Why In Mould Labelling is a Sought Out Option for Packing Products

In-mould labelling is a typical process in which the respective manufacturers place a pre-printed polypropylene label in the mould of packaging during the process of In-Mould Label manufacturers. Hence as the mould gives shape to the end product as well as performs the labelling.\n\nAfter the curing

0 views • 3 slides

BOPP Wrap Around Labels Manufacturer in India

Wrap around labels are roll fed labels available in oriented poly proplyene in pearlised white opaque or natural transparent. We offer oriented polypropylene roll fed labels for 360 degree, full body wrap around labeling of carbonated soft drinks, pet water bottles, beverage, coffee and food product

1 views • 6 slides

BOPP Wrap Around Labels Manufacturer in India

Wrap around labels are roll fed labels available in oriented poly proplyene in pearlised white opaque or natural transparent. We offer oriented polypropylene roll fed labels for 360 degree, full body wrap around labeling of carbonated soft drinks, pet water bottles, beverage, coffee and food product

0 views • 6 slides

Development of Self-Compacting Concrete with Construction and Demolition Waste

This research proposal focuses on developing self-compacting concrete (SCC) using construction and demolition waste. The proposal explores the properties and advantages of SCC, reviews literature on using recycled materials in concrete production, and presents laboratory studies on mechanical proper

1 views • 19 slides

MANUFACTURERS OF SHRINK & & BOPP WRAP AROUND LABELS

Wrap around labels are roll fed labels available in oriented poly proplyene in pearlised white opaque or natural transparent. We offer oriented polypropylene roll fed labels for 360 degree, full body wrap around labeling of carbonated soft drinks, pet water bottles, beverage, coffee and food product

0 views • 3 slides

Recycled Plastics market Tech Innovations Revolutionize Plastic

Recycled Plastics Market Plastic Type(Polyethylene, Polyethylene Terephthalate, Polypropylene, Polyvinyl Chloride, Polystyrene, Other Products), By Source(Plastic Bottles, Plastic Films, Polymer Foam, Other Sources), By Application(Building & Constru

1 views • 4 slides

Flexible Packaging Market Flexible Packaging: Meeting the Needs of a Fast-Paced

Flexible Packaging Market By Packaging Type (Bags, Pouches, Films and Wraps, Others), By Raw Material (Plastic, Paper, Aluminum, Bioplastics, Polyethylene, Polypropylene, Polyethylene Terephthalate, Others), By Printing Technology (Flexography, Digit

0 views • 4 slides

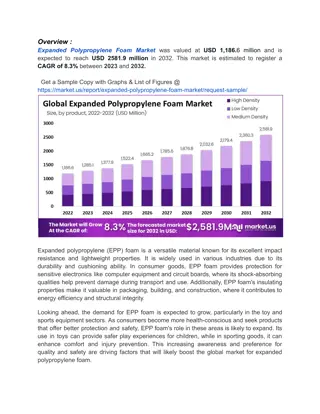

Demand for Impact-Resistant Materials Boosts Expanded Polypropylene Foam Market,

Expanded Polypropylene Foam Market, By Product (High Density, Low Density, and Medium Density), By Application (Bumpers, Roof Pillars, and Other Applications), By End-User(Automotive, Packaging, Consumer goods, Appliances, Oil & Gas), By Region and C

0 views • 4 slides

Polypropylene Market

The global Polypropylene Market size is expected to be worth around USD 193.7 billion by 2033, from USD 115.6 billion in 2023, growing at a CAGR of 5.3% during the forecast period from 2023 to 2033.\nClick here for request a sample: \/\/market.us\/re

1 views • 4 slides

Winners Label Why In-Mould Labels Are Highly in Use - A Detailed Study

In-mould labels are nothing but printed polypropylene labels and it takes the shape of a container post that is directly injected in the mould. The overall process results in making the mould & labels get united together. There are three key process

0 views • 6 slides

Winners Label Why In-Mould Labels Are Highly in Use - A Detailed Study

In-mould labels are nothing but printed polypropylene labels and it takes the shape of a container post that is directly injected in the mould. The overall process results in making the mould & labels get united together. There are three key process

0 views • 6 slides

Incidence of Mesh Fractures in Open Ventral Hernia Repair with Mediumweight Polypropylene Mesh

This study aims to characterize the occurrence of mesh fractures in open ventral hernia repair using mediumweight polypropylene mesh and identify associated risk factors. The research focuses on patients at Cleveland Clinic from January 2014 to April 2022, emphasizing retromuscular placement and a o

1 views • 19 slides

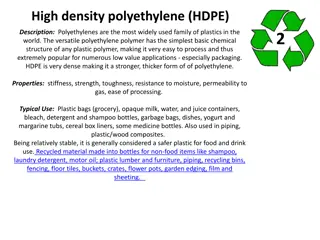

Overview of High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE)

High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are versatile plastics widely used for packaging and other applications. HDPE is known for its stiffness, strength, and resistance to moisture, while LDPE offers flexibility and ease of sealing. Polypropylene (PP) is another popula

0 views • 4 slides

Mechanical Properties of Concrete with Polypropylene Fibre Inclusion

Concrete is a brittle material that is strong in compression but weak in tension. In this study, the focus is on enhancing the mechanical properties of normal concrete by including polypropylene fibers. The inclusion of fibers helps improve crack resistance and flexural strength, acting as crack arr

0 views • 17 slides

In-Mould Labels (IML) Advantages and Benefits for Modern Packaging Solutions

In mould labels are pre-printed polypropylene labels which take the shape of the containers after being directly injected into a mould. In any product, the label serves as an integral part of the final product which is delivered as a pre-decorated it

0 views • 6 slides