Why In Mould Labelling is a Sought Out Option for Packing Products

In-mould labelling is a typical process in which the respective manufacturers place a pre-printed polypropylene label in the mould of packaging during the process of In-Mould Label manufacturers. Hence as the mould gives shape to the end product as well as performs the labelling.nnAfter the curing time, packaging & labelling becomes a single piece. There are three key methods of the in-mould label printing process and these include injection moulding along with blow moulding & thermoforming. Read it on & learn more about the process.

Uploaded on | 1 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

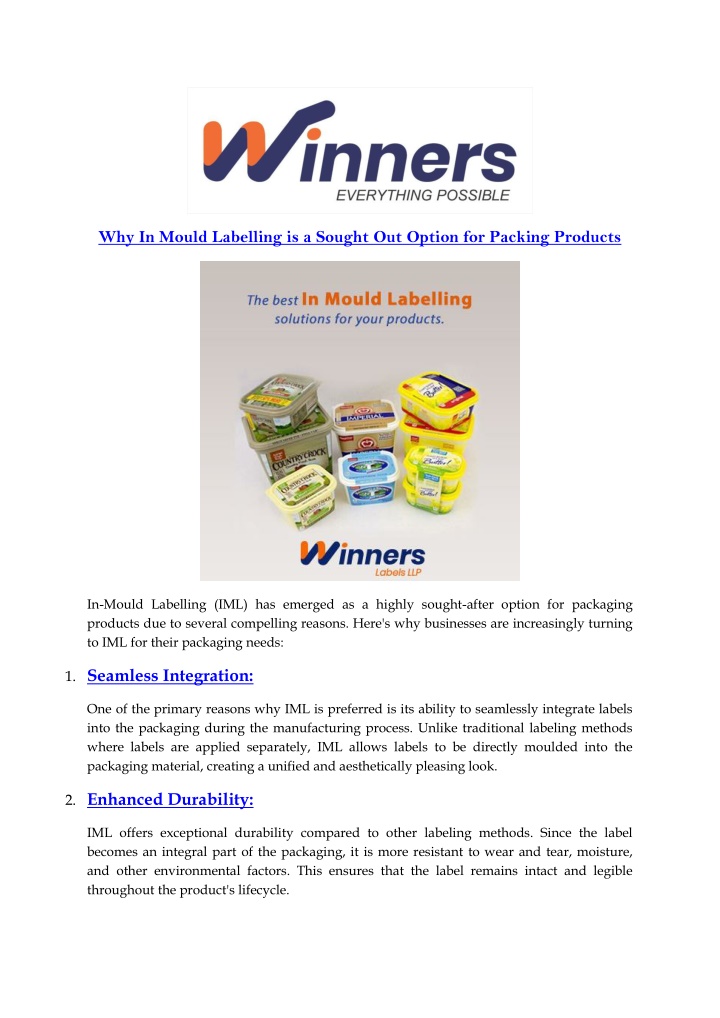

Why In Mould Labelling is a Sought Out Option for Packing Products In-Mould Labelling (IML) has emerged as a highly sought-after option for packaging products due to several compelling reasons. Here's why businesses are increasingly turning to IML for their packaging needs: 1.Seamless Integration: One of the primary reasons why IML is preferred is its ability to seamlessly integrate labels into the packaging during the manufacturing process. Unlike traditional labeling methods where labels are applied separately, IML allows labels to be directly moulded into the packaging material, creating a unified and aesthetically pleasing look. 2.Enhanced Durability: IML offers exceptional durability compared to other labeling methods. Since the label becomes an integral part of the packaging, it is more resistant to wear and tear, moisture, and other environmental factors. This ensures that the label remains intact and legible throughout the product's lifecycle.

3.Vibrant Graphics and Designs: IML enables the use of high-quality graphics and intricate designs, thanks to advanced printing technologies. Manufacturers can achieve vibrant colors, fine details, and attractive finishes, enhancing the visual appeal of the packaging and making products stand out on the shelf. 4.Cost-effectiveness: While the initial investment in IML technology may be higher than traditional labeling methods, it offers long-term cost savings. The durability of IML reduces the need for re- labeling or repackaging due to damaged or worn-out labels, ultimately lowering overall packaging costs. 5.Eco-friendly Solution: IML is considered an environmentally friendly packaging solution. Since the label is integrated into the packaging material, there is no need for additional adhesives or liners, reducing waste and making recycling easier. Additionally, some IML materials are recyclable, further minimizing environmental impact. 6.Resistance to Counterfeiting: IML labels can incorporate security features such as holograms, QR codes, or RFID tags, making them more resistant to counterfeiting. These features help brands protect their products from counterfeiters and reassure consumers of authenticity. 7.Versatility: IML is suitable for a wide range of packaging applications across various industries, including food and beverage, cosmetics, household products, and automotive parts. Its versatility allows manufacturers to create customized packaging solutions tailored to their specific needs. 8.Efficiency in Production: IML streamlines the packaging process by combining labeling and moulding into a single step. This reduces production time and labor costs, making it an efficient choice for high- volume manufacturing. In summary, In-Mould Labelling offers numerous benefits such as seamless integration, durability, vibrant graphics, cost-effectiveness, eco-friendliness, resistance to counterfeiting, versatility, and efficiency in production, making it a highly sought-out option for packaging products across industries.

GET IN TOUCH WITH US: Winners Labels CB - 70, SALT LAKE CITY, KOLKATA - 700 064 CONTACT NO: +91 9830087119 / 9831070140 / 9831016222 EMAIL: INFO@WINNERSLABELS.COM WEBSITE: https://www.winnerslabels.com/ Photo frame Heat Transfer labels manufacturer in India Comb Heat Transfer labels manufacturer in India Oil container Heat Transfer labels manufacturer in India Tiffin box Heat Transfer labels manufacturer in India Bangles Heat Transfer labels manufacturer in India Stationery Heat Transfer labels manufacturer in India ABS container Heat Transfer labels manufacturer in India Container Heat Transfer labels manufacturer in India Pencil box Heat Transfer labels manufacturer in India PP container Heat Transfer labels manufacturer in India Steel Heat Transfer labels manufacturer in India Heat Transfer labels manufacturer in India Paper Heat Transfer labels manufacturer in India In-Mould labels manufacturer in India Tiffin box Heat Transfer labels manufacturer Photo frame Heat Transfer labels manufacturer Oil container Heat Transfer labels manufacturer ABS container Heat Transfer labels manufacturer Stationery Heat Transfer labels manufacturer Comb Heat Transfer labels manufacturer Steel Heat Transfer labels manufacturer PP container Heat Transfer labels manufacturer Bangles Heat Transfer labels manufacturer Paper Heat Transfer labels manufacturer Container Heat Transfer labels manufacturer Pencil box Heat Transfer labels manufacturer In-Mould labels manufacturer Heat Transfer labels manufacturer