Mechanical Properties of Concrete with Polypropylene Fibre Inclusion

Concrete is a brittle material that is strong in compression but weak in tension. In this study, the focus is on enhancing the mechanical properties of normal concrete by including polypropylene fibers. The inclusion of fibers helps improve crack resistance and flexural strength, acting as crack arresters. The research aims to compare the performance of concrete with and without polypropylene fiber, assess durability, and recommend the optimum fiber percentage. Additionally, the literature review discusses the types of fibers, advantages of fibrillated polypropylene fibers, and the hydrophobic nature of polypropylene, which does not affect the water-cement ratio.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

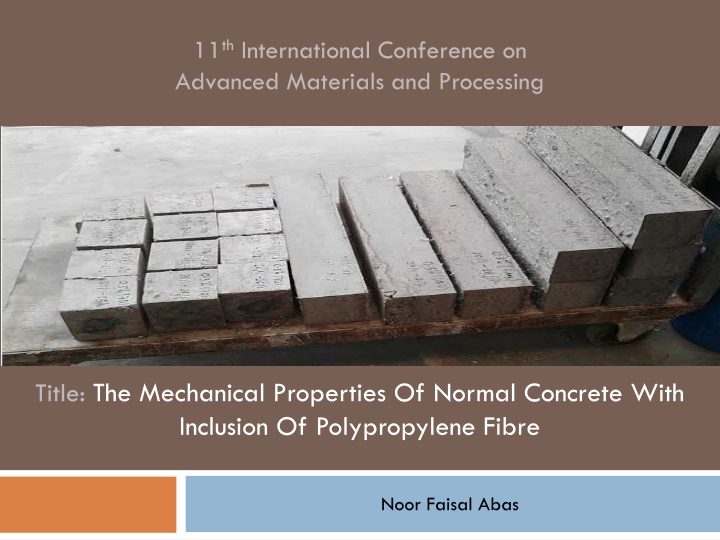

11th International Conference on Advanced Materials and Processing Title: The Mechanical Properties Of Normal Concrete With Inclusion Of Polypropylene Fibre Noor Faisal Abas

INTRODUCTION Concrete is inherent brittle material which related to strong compression but weak in tension Concrete are the most man made product with combination of aggregate,cement,water and admixture. Fibre reinforced concrete are used in improve the existing of crack and enhance the flexural strength. Fibre also act as crack arrester to hold the concrete from a bigger width of crack Polypropylene fibre and steel fibre are popular fibre that usually use in construction industry. Polypropylene are fibre that easy to work it, and don t affect the surface texture or appearance of finished concrete (Cheng & Olsen, 2003)

PROBLEM STATEMENT Concrete are known as brittle and easily crack Crack play a important role as they change concrete structure into permeable elements and consequently with high risk of corrosion Crack exist at all stage in the life of a concrete structure. It can influence by load change due to settlement of plastic, rise curing temperature and etc. (Beeby & R.S, 1995) Crack not only reduce the quality of concrete and make it aesthetically unacceptable but also make structure out of service. Huge crack that significance to structure failure take a great concern in repairing and rehabilitation of structure in time consuming and cost.

OBJECTIVE To compare the mechanical properties of normal concrete and the performance of concrete in addition of polypropylene fibre To examine the durability of concrete when mix with polypropylene fibre To recommend optimum percentage of polypropylene fibre

LITERATURE REVIEW Fibres are divide into 2 type: -Synthetic Fibres Example: Polypropylene fibres, polyester fibres -Natural Fibres Example: Coconut fibre,kenaf fibre,oil palm fibre Polypropylene fibre are divide into 2 type: - Fibrillated -Monofilament

Fibrillated polypropylene fibre Monofilament polypropylene fibre

LITERATURE REVIEW Polypropylene fibre was firstly use in construction industry on year 1965 Usage of fibrillated polypropylene fibre in concrete has portray some advantage over that monofilament due to ease distribution in matrix and improvement on the mechanical bond between fibre and matrix (N.Meamanian, 1991). Polypropylene fibre are known as hydrophobic where it does not absorb water and does not influence in water cement ratio (Amit Rai, 2014). Polypropylene also be function in reduce the micro crack that happen on concrete when curing process and apply of it to improve strength of concrete while the matrix protect the fibre (Dr.T.Ch.Madhari, 2014).

METHODOLOGY LITERATURE SURVEY MIX DESIGN LABORATORY TEST PROGRAMME FLEXURAL STRENGTH COMPRESSIVE STRENGTH WATER ABSORPTION RESULT ANALYSIS FINAL REPORT

METHODOLOGY Doe (Department of the Experiment) method Concrete mix content(kg) Water Cement (kg) Fine aggregate (kg) Coarse aggregate Polypropylene fibre w/c ratio 0% 11.36 17.22 45.97 68.96 0 0.66 0.3% 11.36 17.22 45.97 68.96 0.16 0.66 0.6% 11.36 17.22 45.97 68.96 0.32 0.66 0.9% 11.36 17.22 45.97 68.96 0.48 0.66 Polypropylene fibre are supplied from Timuran Engineering Sdn.Bhd. The length of this type of fibre is 19mm with specific gravity 0.9 kg / dm 3 All mould was filled with mixed concrete, it was placed under the roof for 24 hour to ensure that the concrete are generally hardened. After 24 hour, the mould can be open and the concrete specimens are placed on the water tank for the curing process. The result of each test are take every 7,14,21 and 28 days.

METHODOLOGY Compressive strength test -compressive strength is the important test which give an idea about characteristic of hardened concrete and quality of concrete -The test is done according to BS EN 12390-3:2009. Flexural test - The flexural test used prism specimen where this test using the two points loading up and down arrangement - It is a important test in measure the FRC because fibre are well known in enhancing the flexural strength in concrete. -This test is followed according to BS EN 12390-5-2009 with using GOTECH Universal Testing Machine. Water absorption test -Water absorption test is conducted to determine the absorption ability of the concrete specimens. -It shows by the ratio weight of water absorbed by the composite material for a period of the time to the weight of dry materials.

METHODOLOGY CORE MACHINE FLEXURAL MACHINE COMPRESSIVE TEST MACHINE Core specimen (75mmx100mm) Cube specimen (100mmx100mmx100mm) Prism specimen (500mmx100mmx100mm)

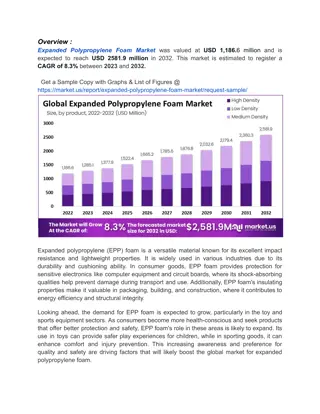

RESULTS & DISCUSSION COMPRESSIVE STRENGTH 18 Compressive Strength (N/mm2) 16 14 12 0%(control) 10 0.30% 8 0.60% 6 0.90% 4 2 0 7 Day 14 Day 21 Day 28 Day Age (Day) The average of 0% compression test (control) 0.3% 0.6% 0.9% 7 Day 13.26 13.15 13.16 11.69 14 Day 14.32 13.90 13.42 12.77 21 Day 14.80 14.82 15.35 13.67 28 Day 16.07 16.25 16.06 14.17 Highest compressive strength 16.25N/mm2(0.3%) & 16.07 N/mm2 (control mix)

RESULTS & DISCUSSION FLEXURAL TEST 12 Flexural Strength ( Mpa) 10 8 0%(control) 6 0.30% 0.60% 4 0.90% 2 0 7 Day 14 Day 21 Day 28 Day Ages (Day) Average of 0%(control) 0.3% 0.6% 0.9% Flexural test 7 Day 6.52 7.44 7.54 7.39 14 Day 6.78 9.30 8.53 9.49 21 Day 8.21 9.34 9.31 10.40 28 Day 7.80 9.72 9.94 10.23 Highest flexural strength is 10.23 Mpa (0.9%) while control just 7.80 Mpa .

RESULTS & DISCUSSION WATER ABSORPTION TEST 7 Water absorption test (%) 6 5 0%(control) 4 0.30% 3 0.60% 2 0.90% 1 0 7 Day 14 Day 21 Day 28 Day Ages (Day) Average of 0%(control) 0.3% 0.6% 0.9% Water absorption test 7 Day 6.33 6.09 6.44 6.48 14 Day 6.10 5.82 5.43 6.00 21 Day 6.26 6.06 5.47 5.52 28 Day 5.43 5.19 5.34 5.48 The lowest result is 5.19% (0.3%) while for the control is just 5.43% (control) In theory, the water absorption decrease with the age because of quality of concrete that improve according to reduction of water absorption in the specimen.

CONCLUSION The inclusion of polypropylene fibre in normal concrete doesn t enhance the compressive strength when the highest result was 0.3% while above than 0.3% become decrease.Beside,normal concrete got lower result that 0.3%. According to the flexural test, it can conclude that increases flexural strength is highly depend on the content of polypropylene fibre .Thus, 0.9% has higher result 10.40 Mpa compare to normal concrete that just 8.21 Mpa. Overall concrete that inclusion with fibres has high result than normal concrete. The inclusion of Polypropylene fibres in normal concrete is effectively improve in durability of fibre reinforced concrete where in theory, the water absorption decrease with the age because of quality of concrete that improve according to reduction of water absorption in the specimen. The lowest result is 0.3% with 5.19% at 28 day . The optimum percentage of fibre was 0.9% of polypropylene fibre where it has higher result in flexural test. The higher flexural results are depending on the fibre content. Inclusion of fibre has proved that it can slow down the propagation of crack.

REFERENCE 1)A.M.ALhozaimy, P. &. (1996). Mechanical Properties of Polypropylene Fibre Reinforced Concrete and The Effect of Pozzolanic Material. Cement & Concrete Composite, 18, 85-92. 2)Amit Rai, D. Y. (2014). Application and Properties of Fibre Reinforced Concrete. Journal of Engineering Research and Application, 4 (5), 123-131. 3)Beeby, A., & R. N. (1995). Designer's Handbook to Eurocode 2:1 Design of Concrete Structure. USA: Thomas Telford Service Ltd. 4)Carpinteri, A. (1986). Mechanical Damage and Crack Growth In Concrete (First ed.). Netherland: Martinus Nijhoff Publishers. 5)Cheng, F.-T., & Olsen, E. (2003). Concrete Countertop. New Town: The Tounton Press. 6)Dr.T.Ch.Madhari, L. R. (2014). Polypropylene Fibre Reinforced Concrete. International Journal of Emerging Technology and Advanced Engineering, 4 (4), 117. 7)Gonzalo Martinez, F. G. (2011). Mechanical Properties of Polyproplyene Fibre Reinforced Concrete after Gamma Radiation. 42 (5), 567-572. 8)N.Meamanian, A. &. (1991). Distribution and Opening of Fibrillated Polypropylene Fibre In Concrete. Cement and Concrete Composite, 13, 107-114. 9)Pillai, S. U., & Menon, D. (1998,2003). Reinforced Concrete Design (Second ed.). India, New Delhi: Tata McGraw-Hill Publishing Company Limited.