Optimization of Crude Oil Blend Scheduling in Industrial Refineries

Explore a discrete-time model for scheduling optimization in a complex industrial-sized refinery, focusing on feedstock storage assignment and crude blend scheduling. The objective is to study various time steps and unit configurations to maximize efficiency and productivity. Various benchmarks and past studies are referenced, highlighting the importance of discrete-time modeling for such large-scale refinery operations.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

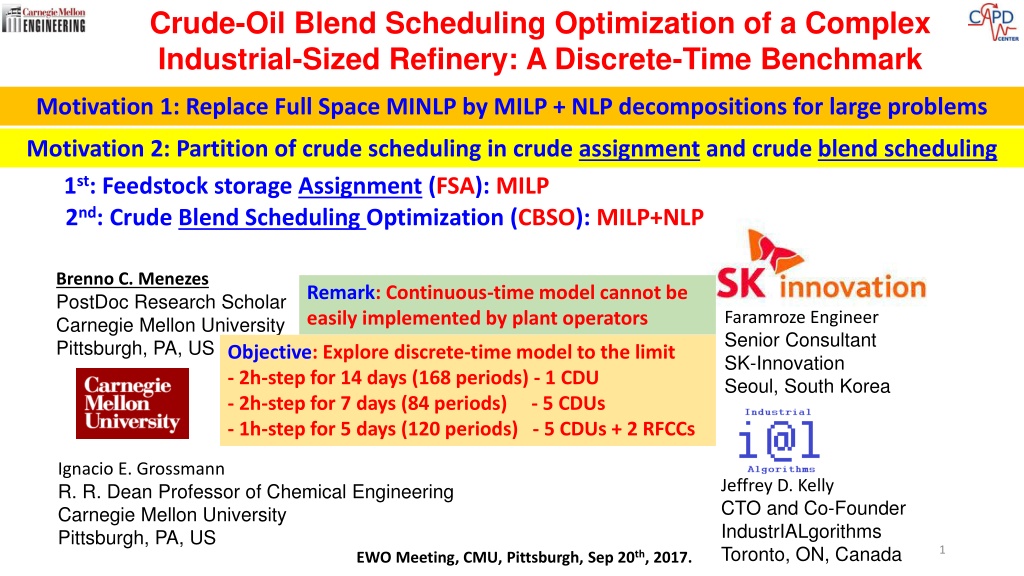

Crude-Oil Blend Scheduling Optimization of a Complex Industrial-Sized Refinery: A Discrete-Time Benchmark Motivation 1: Replace Full Space MINLP by MILP + NLP decompositions for large problems Motivation 2: Partition of crude scheduling in crude assignment and crude blend scheduling 1st: Feedstock storage Assignment (FSA): MILP 2nd: Crude Blend Scheduling Optimization (CBSO): MILP+NLP Brenno C. Menezes PostDoc Research Scholar Carnegie Mellon University Pittsburgh, PA, US Remark: Continuous-time model cannot be easily implemented by plant operators Faramroze Engineer Senior Consultant SK-Innovation Seoul, South Korea Objective: Explore discrete-time model to the limit - 2h-step for 14 days (168 periods) - 1 CDU - 2h-step for 7 days (84 periods) - 5 CDUs - 1h-step for 5 days (120 periods) - 5 CDUs + 2 RFCCs Ignacio E. Grossmann R. R. Dean Professor of Chemical Engineering Carnegie Mellon University Pittsburgh, PA, US Jeffrey D. Kelly CTO and Co-Founder IndustrIALgorithms Toronto, ON, Canada 1 EWO Meeting, CMU, Pittsburgh, Sep 20th, 2017.

Whole Scheduling: from Crude-Oils to Fuels 1996: Lee, Pinto, Grossmann and Park (MILP), discrete-time 2004: Randy, Karimi and Srinivasan (MILP), continuous-time 2009: Mouret, Grossmann and Pestiaux: MILP+NLP continuous-time 2014: Castro and Grossmann: MINLP ; MILP+NLP, continuous-time 2015: Cerda, Pautasso and Cafaro: MILP+NLP, continuous-time (336h: 14 days; binary 4,000; continuous 6,000; constraints 100K; CPU(s) 500) Crude-Oil Scheduling Problem Fuel gas LPG NHT Naphtha Charging or Feed Tanks REF Transferring or Feedstock Tanks Gasoline B L E N S KHT Kerosene 2016 Goal: solve the SK Ulsan refinery scheduling for a week (38 crude, 2 pipelines, 23 storage tanks, 11 feed tanks, 5 CDUs) DHT Diesel Diluent Receiving or Storage Tanks RFCC MINLP Fuel oil Current Benchmark Relax y [0,1] as (0,1) in NLP FCC Asphalt VDU DC DICOPT (5,000 binary variables) Crude-to-Fuel Transformation Crude-Oil Management Blend-Shop Crude Transferring Crude Dieting Fuel Blending MINLP -> MILP + NLP Hydrocarbon Flow Refinery Units Crude Receiving Fuel Deliveries 2 EWO Meeting, Sep 20th, 2017.

Whole Scheduling: from Crude-Oils to Fuels 1996: Lee, Pinto, Grossmann and Park (MILP), discrete-time 2004: Randy, Karimi and Srinivasan (MILP), continuous-time 2009: Mouret, Grossmann and Pestiaux: MILP+NLP continuous-time 2014: Castro and Grossmann: MINLP ; MILP+NLP, continuous-time 2015: Cerda, Pautasso and Cafaro: MILP+NLP, continuous-time (336h: 14 days; binary 4,000; continuous 6,000; constraints 100K; CPU(s) 500) Crude-Oil Blend Scheduling Problem CBSO Fuel gas FSA FSA LPG NHT Naphtha Charging or Feed Tanks REF Transferring or Feedstock Tanks Gasoline B L E N S (MILP) KHT Kerosene 2016 Goal: solve the SK Ulsan refinery scheduling for a week (38 crude, 2 pipelines, 23 storage tanks, 11 feed tanks, 5 CDUs) DHT Diesel Diluent Receiving or Storage Tanks RFCC 1st Feedstock Storage MINLP -> MILP + NLP Assignment (FSA) Fuel oil FCC Asphalt VDU DC Minimize the Quality Variation Feedstocks -> Storage Tanks Crude-to-Fuel Transformation Reduces optimization search space for further scheduling 2nd Crude Blend Scheduling Optimization (CSBO) Crude-Oil Management Blend-Shop Crude Transferring Crude Dieting Fuel Blending Yields Rates (crude diet, fuel recipes, conversion) (MILP+NLP) Hydrocarbon Flow (Menezes, Kelly & Grossmann, 2015) Includes logistics details Refinery Units PDH Decomposition (logistics + quality problems) 1. JD Kelly, BC Menezes, IE Grossmann, F Engineer, 2017, FOCAPO. 2. JD Kelly, BC Menezes, F Engineer, IE Grossmann, 2017, FOCAPO. EWO Meeting, Sep 20th, 2017. Crude Receiving Fuel Deliveries 3

Automated in Python/IMPL: FSA + Root + CBSO with Factors FSA root yjit: Current assignments 1st: Feed tanks to CDU; 2nd: Storage to Feed tanks; 3rd: Feedstock Storage Assignment xm: CDU Throughputs (varying for the remaining amount in the feed tanks and with performance term to smooth throughput) CBSO Multi-period NLP for near past, current and near future assignments Quality Logistics Quality Logistics (MILP) Quality Setups Score Setups Yields Factors Qualogistics Quality Sub-Solver (NLP) Yields (for CDU) Factors (for Storage to Feed tanks) Logistics Sub-Solver (MILP) 4 EWO Meeting, Sep 20th, 2017.

2017 (simple crude-oil topology + towers in cascade) Blender updated as [0,1] from the NLP PDH converges to 3% after 4 iterations 5

2017 (simple crude-oil topology + towers in cascade) Blender recipes updated from the NLP PDH converges to 3% after 3 iterations 6

Reproduce an Industrial-Sized Problem using Factors Units: 5 CDUs without modes + 4 Blenders + VDU + 2 RHDS + 2 RFCC Tanks: 20 storage and 10 feed; 2 intermediate for each unit 5 days: 120-hours discretized into 1-hour time-period duration The logistics problem (MILP): 45,753 continuous + 28,543 binary variables 8,612 equality and 72,368 inequality constraints Non-Zeros: 628,795; Degrees-of-freedom: 63,427 CPU(s): 170 seconds (2.83 min) in 8 threads CPLEX 12.6. The quality problem (NLP): 121,394 continuous variables 99,099 equality and 516 inequality constraint Non-Zeros: 125,462; Degrees-of-freedom: 22,295 CPU(s): 933 seconds (15.55 min) in the IMPL SLP engine linked to CPLEX 12.6. MILP-NLP gap: 3% after 5 PDH iterations. IMPL (Industrial Modeling and Programming Language) using Intel Core i7 machine at 2.7 Hz with 16GB of RAM 7 EWO Meeting, Sep 20th, 2017.

NEXT STEPS 2016 (real crude-oil topology + simplified towers) 2018 (Full crude-oil topology and Full Refinery) 2017 (simple crude-oil topology + towers in cascade) EWO Meeting, Sep 20th, 2017.

Conclusion Novelty: Segregates crude management in storage assignment1 and crude blend scheduling.2 Phenomenological decomposition in logistics (MILP) and quality (NLP) problems applied in a scheduling problem updating crude-oil recipes and distillate yields. Impact for industrial applications: UOPSS modeling, pre-solving, and parallel processing, reverse polish notation, complex number for derivatives, among others, solved for the 1st time a highly complex refinery scheduling. (MILP 50K binary variables and NLP 120K continuous with 60% NLP) 1. JD Kelly, BC Menezes, IE Grossmann, F Engineer, 2017, FOCAPO. 2. JD Kelly, BC Menezes, F Engineer, IE Grossmann, 2017, FOCAPO. 9 EWO Meeting, Sep 20th, 2017.

Thank You Q?&A! www.industrialapplications.club www.induapps.club brenno@induapps.club 10