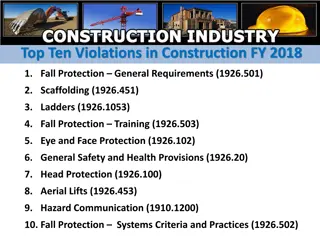

Ensuring Eye Safety in Construction Workplaces

Eye injuries are a common occurrence at construction sites, with thousands happening daily in the US. Construction workers face a high risk of eye injuries due to various factors like dust, metal, wood, and other particles. Wearing appropriate eye protection is crucial to prevent such injuries, as regular glasses or contact lenses do not offer sufficient protection. This guide emphasizes the importance of selecting the right eyewear for different job requirements and highlights the need for emergency procedures in case of accidents.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

OSHA Construction Eye Protection June 14, 2019 By Team Safesite

Quick Overview 2000 eye injuries occur everyday at work in the US. Construction workers have one of the highest eye injury rates.

Common Causes Of Eye Injuries 2000 eye injuries occur everyday at work in the US and construction workers have one of the highest eye injury rates. Particles of dust, metal, wood, slag, drywall, cement etc. are the most common source of eye injury to carpenters. Even minor eye injuries can cause lifelong vision problems and suffering a simple scratch from sawdust, cement, or drywall can cause corneal erosion that is constantly painful

Wearing the right type of eye protection equipment is the key to preventing most on-the-job eye injuries.

If your workplace has airborne dust or grit and a risk of flying particles or splashing chemicals, you need eye protection. Regular glasses do not provide adequate protection, and contact lenses are never a substitute for safety gear. Many types of eye protection exist, including designs that can be worn over prescription glasses. Worksite Tips:

Choosing Eyewear 1. Select the protective eyewear best suited to the job. 1. Glasses with impact-resistant lenses and side shields provide adequate protection for most types of work. 1. Flexible-fitting or cushion-fitting goggles fit easily over prescription glasses and provide front and side protection. 1. Prescription glasses that meet protective requirements of safety glasses are available

Choosing Eyewear, continued 5. Special purpose eyewear, such as chemical or chipping goggles, provide maximum protection from fumes and flying debris. 6. Full face shields may be worn in addition to protective eyewear when it's necessary to protect from impact hazards. 7. Full face shields worn by themselves do not adequately protect from impact hazards.

Emergency Procedures 1. Know the locations of eyewash stations, face-washing units and first-aid equipment. 1. Complete required training and know how to use emergency equipment. 1. Report accidents to your supervisor and get medical help immediately.

Potential Eye Injuries 1. Dust, dirt, metal or wood chips entering the eye from activities such as chipping, grinding, sawing, hammering, the use of power tools or strong wind 1. Chemical splashes from corrosive substances, hot liquids and solvents 1. Radiant energy from welding, harmful rays from the use of lasers or other radiant light, as well as heat, glare, sparks, splash and flying particles

Digitize Your Safety Workflow Safesite is a FREE, easy to use digital safety management tool. Get started with safety inspections, audits, and checklists in seconds.