Synergistic Co-Processing of Natural Gas and Biomass for Hydrogen-Rich Syngas Production

Examining the synergistic co-processing of natural gas and biomass to produce hydrogen-rich syngas, this study explores reactor configurations, motivation for lab-scale gasification, challenges in biomass utilization, and catalyst-based design of experiments. Results and discussions cover gasifier reactor setups, complex reaction engineering, and the potential for commercial applications.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

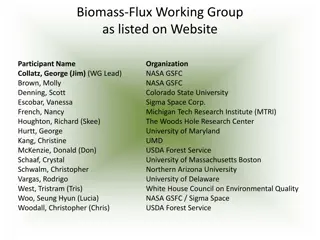

Synergistic Natural Gas Biomass Co-processing to Produce Hydrogen Rich Syngas Amoolya D. Lalsarea Jianli Hua Ali C. Sivrib Cosmin E. Dumitrescub a: Chemical and Biomedical Engineering b: Mechanical and Aerospace Engineering West Virginia University

Outline Motivation Results and discussion Gasifier reactor Proposed reaction pathway configuration Process Scale-up and Path to Natural gas-biomass Commercial Application co-processing Conclusions Design of experiments Future Work 2

Motivation Lab scale scale-up of gasification reactor to bench scale fluidized bed reactor Complexity of fluidization hydrodynamics Complex reaction engineering of biomass / coal gasification Gasification process development to improve efficiency Process intensification 3

Gasifier Reactor Configuration Fixed Bed Reactor Setup Bubbling Fluidized Bed Reactor Setup 4

Natural gas Biomass Co-processing Biomass Utilization Challenges Highly variable composition of feedstock2 Complexity of solid biomass handling3 Low energy density and high oxygen content1,2 Lignin representation HDO of phenolic (C OH), carbonyl (C=O) functional groups, and fufurals Advantages of Shale gas / Natural gas Abundant availability, low prices High energy density4 High H / Ceff ratio of methane (4) as compared to biomass (0.3)5 1. Ref.: https://www.eia.gov/outlooks/aeo/ 2. S. V. Vassilev, D. Baxter, L. K. Andersen, C. G. Vassileva, Fuel 2010, 89, 913 933 3. M. R. Wu, D. L. Schott, G. Lodewijks, Biomass and Bioenergy 2011, 35, 2093 2105 4. A. Demirba , Energy Sources 2002, 24, 601 610 5. K. Bu kowska, E. Klimiuk, in Biomass for Biofuels, 2016, 121 153 5

Design of Experiments Catalyst FeMo / ZSM-5 FeMo / CNF Mo 4 wt.% 4 wt.% Fe 0.5 wt.% Zeolite 0.5 wt.% Carbon Support Fixed Bed Reactor Setup Fluidized Bed Gasifier Setup nanofiber Hardwood Biomass Weight % Reaction temperature: 850oC to 950oC Carbon (C) Hydrogen (H) Oxygen (O) Moisture Ash 45.25 4.65 49.2 7.16 0.32 CH4: 5 to 15 vol.%, CO2: 1 vol.% Balance: Nitrogen (N2) Catalyst to Biomass wt. ratio 3:4 Product Analysis: Inficon Fusion Micro-GC 6

Results and Discussion 100 Hydrogen Carbon Monoxide Carbon Dioxide Methane Fixed bed reactor studies 0.5 % Fe - 4% Mo / ZSM-5 84 80 Biomass gasification at 900oC No catalyst ZSM-5 60 Methane activated synergistic biomass 55 % Conc. 44 32 40 gasification 25 24 Methane - carbon dioxide activated 19 16 20 14 08 10 13 12 06 synergistic biomass gasification 01 01 0 Feed1 Feed1 H2/CO: 0.57 Feed2 H2/CO: 5.9 Feed3 H2/CO: 1.94 H2/CO: 0.35 Fluidized bed reactor studies Feed1: Biomass, Feed2: Biomass + 5% CH4, Feed3: Biomass + 5%CH4 + 1% CO2 Non-catalytic biomass gasification at 900oC 7

Biomass Gasification on FeMo catalyst in absence of methane H2 CO CO2 CH4 70% Hardwood biomass gasification at 55% 54% 60% 850oC, 950oC on ZSM-5 support and Normalized Conc. 50% FeMo/ZSM-5 catalyst 44% 40% High methane concentration due to 24% 24% 30% 25% 19% reverse steam methane reforming in 20% 16% 16% 11% FeMo/ZSM-5 10% 5% 6% H2:CO ratio < 1 0% 950 ZSM-5 850 FeMo1 950 FeMo1 Temperature (oC), Catalyst 8

Biomass Gasification on FeMo/ZSM-5 with 5 to 15% CH4 Biomass CH4 reaction at850oC Biomass CH4 reaction at950oC H2 CO CO2 CH4 H2 CO CO2 CH4 84% 77% 100% 100% 80% 76% 81% 80% 80% 74% Normalized Conc. Normalized Conc. 60% 60% 40% 40% 21% 20% 18% 20% 17% 14% 20% 11% 5% 5% 2% 3% 3% 4% 1% 1% 1% 1% 1% 1% 0% 0% 5% CH4 H2:CO = 6 10% CH4 H2:CO = 5.0 15% CH4 H2:CO = 4.2 5% CH4 H2:CO: 7.4 10% CH4 H2:CO: 3.7 15% CH4 H2:CO: 3.7 9

Temperature effect on methane activated biomass gasification Biomass and 5% CH4 reaction Biomass and 10% CH4 reaction 100% H2 CO CO2 CH4 H2 CO CO2 CH4 84% 100% 80% 81% 77% 80% 80% Normalized Conc. Normalized Conc. 60% 60% 40% 40% 21% 20% 20% 17% 14% 11% 5% 5% 1% 1% 1% 1% 1% 1% 0% 0% 850 950 Temperature (oC) 850 950 Temperature (oC) H2:CO = 7.5 H2:CO = 5.9 H2:CO = 3.8 H2:CO = 5 10

CH4 CO2 Activated Biomass Gasification High temperature catalytic Hydrogen Carbon Monoxide Carbon Dioxide Methane 60 55.9 methane carbon dioxide activation 50 Catalyst: FeMo/ZSM-5, FeMo/CNF 40 % Conc. H2:CO = 2 Zeolite and carbon nanofiber catalyst 31.6 29.3 30 20 16.3 16.3 support 10.3 10 8.36 6.36 Gas yieldZSM-5 < Gas yieldCNF 0 ZSM-5 CNF Catalyst Support H2/CO: 1.94 H2/CO: 1.97 11

Proposed Reaction Pathway Adsorption of biomass components like phenols, furfurals, and carbonyl oxygen on oxophilic Mo active site Decoupling of carbon oxygen bond to form steam adsorbates 12

Synergistic Steam Methane Reforming Synergistic Bi-reforming 13

Hydrogen Carbon Monoxide Carbon Dioxide Methane 83.8 100 Feed1: Biomass 80 Feed2: Biomass + 5% CH4 Feed3: Biomass + 5% CH4 + 1% CO2 FB Fixed bed 55 % Conc. 60 38.4 42.1 31.6 40 19 16.3 10.3 14.2 20 8.72 13 8.36 12 8.67 BFB Bubbling fluidized bed 0.93 0 F1 / FB F1 / BFB F2 / FB F3 / FB Feed (F#) / Reactor Type (FB: Fixed Bed, BFB: Bubbling Fluidized Bed) H2/CO: 0.35 H2/CO: 0.91 H2/CO: 5.9 H2/CO: 1.94 14

Hydrogen Carbon Monoxide Carbon Dioxide Methane 70 55 50 60 38.4 50 42.1 % Conc. Fluidized Bed Product Gas Composition 40 15 30 17 19 20 16 8.67 13 8.72 12 10 0 Biomass_fixed bed H2/CO: 0.35 Biomass_fixed bed H2/CO: 0.91 Coal - 10% Steam_BFB H2/CO: 3.23 Biomass and coal gasification at 900oC 15

Conclusions Natural gas biomass and natural gas carbon dioxide - biomass synergy Hydrogen rich syngas for applications like fuel cells and conventional processes like ammonia synthesis Synthesis gas for value added chemical synthesis Process scale-up is achievable by continuous feeding of biomass-catalyst in a fluidized bed or moving bed reactor 16

Future Work Replicating all the fixed bed experimental conditions on bubbling fluidized bed setup Achieve continuous streamlined feeding of coal / biomass Extended continuous operation of fluidized bed reactor 17

Publications 1. Hydrogen Rich Syngas Production through Synergistic Methane Activated Catalytic Biomass Gasification; Amoolya Lalsare, Yuxin Wang, Qingyuan Li, Ali C. Sivri, Cosmin E. Dumitrescu, Jianli Hu (under review at ACS Sustain Chem Eng) 2. Syngas (H2:CO = 2) production through methane carbon dioxide activated synergistic bi-reforming in catalytic biomass gasification; Amoolya Lalsare, Ali C. Sivri, Ryan Egan, Roman J. Vukmanovich, Cosmin E. Dumitrescu, Jianli (submitted to ChemSusChem) 18

Acknowledgements Authors are pleased to acknowledge U.S Department of Energy and National Energy Technology Laboratory, Morgantown along with Leidos Research Support Team for the continuous support and cooperation for the specific work and broadly for the NETL Gasifier Support Stand Project 19

Thank you! Questions? 20

Gas Yield Tar Char 100 2 3 5 5 7 8 9.9 12.5 10 13 11 15 11 12 80 Yield (mole%) 60 88 87.5 90.1 84 84 82 40 80 80 20 0 850, 0 950, 0 850, 5 850, 10 850, 15 950, 5 950, 10 950, 15 Temperature (oC), CH4 (vol.%) 21