Scaling up the Use of Machine Learning in Chemical Process Industries - Solvay

Solvay is utilizing machine learning to improve the production process in the chemical process industries. Join the Solvay Discovery Summit at JMP Europe Sitges on 7th March 2023.

- machine learning

- chemical process industries

- Solvay Discovery Summit

- production process

- Solvay

- digital transformation

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Scaling up the Use of Machine Learning in Chemical Process Industries - Solvay Discovery Summit JMP Europe Sitges (Barcelona), 7th March 2023 David Peig - Digital Champion GBU Soda Ash & Derivatives, Solvay Carlos P rez - Industrial Data Scientist, Solvay Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 1

Summary 1. Solvay today: Key figures 4. Scaling up JMP at GBU SA&D Awareness sessions/Training Practical use cases 2. GBU Soda Ash & Derivatives: Key figures 5. JMP add-in to connect to MES 3. How machine learning helps to improve our production process? 6. Main challenges and lessons learned Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 2

1. Solvay Today: Key figures We are a science company, founded in 1863, whose technologies bring benefits to many aspects of daily life. Our innovative solutions contribute to safer, cleaner, and more sustainable products found in homes, food and consumer goods, planes, cars, batteries, smart devices, health care applications, and water and air purification systems. Our Group seeks to create sustainable shared value for all, notably through its Solvay One Planet plan crafted around three pillars: protecting the climate, preserving natural resources and fostering better life. Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 3

2. GBU Soda Ash & Derivatives: key figures Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 4

Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 5

Complex continuous production process: Solvay process Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 6

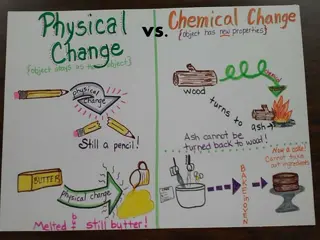

3. How machine learning can help to improve our production process? Our strategy: to be competitive and keep our leadership position in a global commodity market (Soda Ash) and premium markets (BICAR) Objective: reduce as much as possible the variable and fixed costs in our manufacturing sites while ensuring the overall equipment efficiency (OEE) and quality of our products: Variable costs: Yield (Na precipitation Yield in Carbonatation sector) Energy efficiency (Distillation sector, calcination sector, lime kilns ) Fixed costs: Maintenance costs (unplanned mechanical breakdowns in industrial assets, regular maintenance/cleaning, etc) Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 7

3. How machine learning can help to improve our production process? Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 8

3. How machine learning can help to improve our production process? Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 9

4. Scaling up JMP in GBU SA&D 4.1 Awareness session and training Initiative developed online in 2021 47 engineers in the GBU SA&D Lead by Industrial Data Scientist team (Corporate) Content: Awareness session (1 day) Statistical thinking part (7 days, individual online course) JMP introduction part (7 days, individual online course + practical exercises + plenary session) JMP machine learning techniques (15 days, individual online course + practical exercises + plenary session) Selection of real cases to solve + regular support with weekly plenary meetings & individual coaching Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 10

4.2 Practical use cases (1) Title: Increase Na Yield precipitation in Rheinberg (Germany) and Torrelavega (Spain) sites Objectives of JMP usage: To screen multiple variables and select the most important ones to explain the variability of the target (Na Yield) Predictor screening Intuitive and code free advanced analytics tool To visualize the long-term variability of the target and its relationship between the most important variables. To elaborate statistical reports about the performance of different approaches Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 11

4.2 Practical use cases (2) Title: Root causes for the CO3 content in BICAR variability increase (product quality) Objectives of JMP usage: To screen multiple variables and select the most important ones to explain the variability of the target (CO3 content in the final product) Predictor screening To visualize in a graphical way the interaction between the process variables and the target to generate debate between process engineers/operators. To help on decision making process to reduce the variability of the target and therefore the need of downgrading the product. Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 12

5. JMP Add-in to connect to MES Open-source Add-in to automate the data extraction tasks from industrial historians IP.21 and PI 98 sites IP.21 and PI 10k-100k sensors per site Integrates description and engineering units Summary table Time series table ADD, REFRESH, UPDATE Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 13

5.2 JMP Add-in to connect to MES Enable data analytics with JMP Analysis done on latest recorded data Dashboard Summary table Time series table ADD, REFRESH, UPDATE Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 14

6. Main challenges and lessons learned Around 20% of the target population continue using JMP in a routine basis in the GBU SA&D two years after the awareness campaign/training. The main blocking points identified are: Resistance of change. Some people are more comfortable using Minitab or only excel files. Lack of time: priorities in the role of production/process engineers not always fully oriented on process optimization (too much reporting, etc). The points to keep during this process are: Awareness session with practical industry successful examples Predictor screening tool as key tool for variability sourcing combined with process expertise Combination of plenary sessions with individual practise with the tool Points to reinforce/implement for the future: To convince the site management about the importance of analytics for the production/process engineers to launch awareness sessions dedicated for them Strong individual coaching for production/process engineers when developing the first projects using JMP Digital Transformation of the GBU Soda Ash & Derivatives - Solvay page 15