Overview of Activated Sludge Process in Wastewater Treatment

The activated sludge process involves maintaining a biological mass in suspension within a reactor through mixing. Bacteria are returned from the clarifier to maintain high solids concentration. The principle of this system revolves around sludge age and equilibrium. Different types and modifications of the process like conventional, tapered aeration, step aeration, and high purity oxygen systems aim to optimize wastewater treatment efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Maintain an adequate biological mass in suspension within the reactor by mixing. In most processes, the bacteria is returned from the secondary clarifier in order to maintain a high solids concentration.

The principal of suspended growth system The basic factor in design, control, and operation of suspended growth system is (sludge age). For an equilibrium system Quantity of solids produced = quantity of solids lost

The explicit assumption of the model up are: 1. Waste utilization occur in the biological reactor. 2. Total biological mass in the system is equal to the total biological mass in the reactor.

Important type and modifications of activated sludge process Conventional process: Consist of a rectangular basin, a clarifier, andd a solid return line from the clarifier bottom.

Tapered aeration process: This process attempt to match the oxygen supply to demand by introducing more air at the head.

Step aeration process Distribute the incoming flow to a number of points along the basin

High purity oxygen system Using pure oxygen in treatment process. Two process configurations are available a. Closed reactor with high purity oxygen b. Open reactor with fine bubble diffusion at the tank .

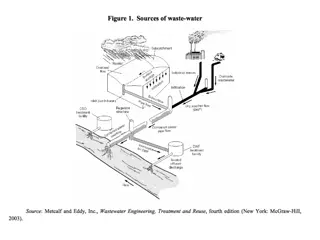

5.9 Biological (Secondary) Treatment System The purpose of primary treatment is to remove suspended solids and floating materials. In many situations in some countries, primary treatment with the resulting removal of approximately 40 60 percent of the suspended solids and 25 to 35 percent of BOD5 together with removal of material from the wastewater, is adequate to meet the requirement of the receiving water body. If primary treatment is not sufficient to meet the regulatory effluent standards, secondary treatment using a biological process is mostly used for further treatment. Biological treatment processes provide similar biological activities to waste assimilation; which would take place in the receiving water, but in a reasonably shorter time. Secondary treatment may remove more than 85 percent of BOD5 and suspended matter; but is not effective for removing nonbiodegradable organics, heavy metals and microorganisms. 13 of 24

5.10 Activated Sludge Process This process is the most widely used process for secondary treatment of wastewater. The wastewater continuously enters and aeration tank where previously developed biological flocs are brought into contact with the organic materials of the wastewater. Air or oxygen-enriched air is continuously injected into the aeration tank as an oxygen source to keep the system aerobic and the activated sludge in suspension. Approximately 8m3 of air is required for each m3 of wastewater. The mixture of wastewater and activated sludge in the aeration basis is called mixed liquor. The biological mass (biomass) in the mixed liquor is called the mixed liquor suspended solids (MLSS) or mixed liquor volatile suspended solids (MLVSS). The microorganism in MLSS are composed of 70-90 percent organic and 10 30 percent inorganic matter. The microbial growth in the mixed liquor is maintained in the declining or endogenous growth phase to ensure good settling properties. 14 of 24

After a certain reaction time (6-8h), the mixed liquor is discharged from the aeration tank to a secondary sedimentation basin (settling tank, clarifier) where the suspended solids are settled out from the treated wastewater by gravity. Most concentrated biological settled sludge is recycled back to the aeration tank (so called return activated sludge, RAS) to maintain a high population of microorganism to achieve rapid breakdown of the organics in the wastewater. The volume of RAS is typically 20-30 percent of the wastewater flow. 5.10.1 Aeration periods and BOD loadings The empirical design of activated sludge is based on BOD loading, food-to- microorganism ratio (F/M), sludge age and aeration period. For normal domestic sewage, the aeration period commonly ranges from 4 to 8h with an air supply 3.7 15.0m3/m3 of wastewater. 15 of 24

5.11 F/M Ratio The F/M ratio is used to express BOD loadings with regard to the microbial mass in the process. The value of the F/M ratio can be calculated by the following equation. F/M = BOD, kg/d MLSS, kg Where F/M = food to microorganism ratio, kg of BOD per day per kg of MLSS. BOD = wastewater 5-day BOD, mg/L MLSS = mixed liquor suspended solids in the aeration tank, mg/l * Conventional Step Aeration, F/M ratio = 0.2 0.5 16 of 24