Sludge Treatment and Disposal Methods in Wastewater Management

This comprehensive guide covers various aspects of sludge treatment and disposal in wastewater management processes. It includes information on the composition of sewage sludge, production estimates, sludge content percentages, and calculations for determining sludge volume under different treatment scenarios such as digestion, dewatering, and incineration.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

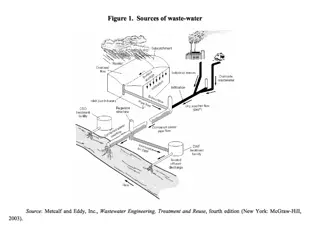

Sewage sludge consist of organic and inorganic solids. The specific gravity of inorganic (2.5) while the organic matter has a specific gravity of 1.01 to 1.06. In secondary process, the solids generated as below: 1. In attached growth process, 0.4 0.5 kg solids produced / kg BOD applied. 2. In suspended growth process ranging from 0.2 to 1.0 kg solids produced/ kg BOD applied depending on sludge age.

ex/ Estimate the solids production from a trickling filter plant treating 1000 m3/ day with a BOD of 210 mg/L and S.S. of 260 mg/L. Assume primary clarifier removes 30% of the BOD and 60% of the influent solids. Sol. The removal in the primary = 0.6 * 260 = 156 mg/L Production in the secondary = 0.7 * 210 * 0.5 = 74 mg/L Total solids production will be approximately : {(156 + 74) * 1000 * 1000} / 106 = 230 kg/day.

Sludge content: The sludge contains amount of water depending on the process involved: Trickling filter plus primary sludge may range from 5 10 % solids. Activated sludge plus primary from 2-5 % solids Activated sludge by itself may contain less than 1% solids.

Ex/ A wastewater plants produce 1000 kg of dry solids / day at moisture content of 95% the solids are 70% volatile with a specific gravity of 1.05 and 30% nonvolatile with a specific gravity of 2.5. Determine the sludge volume: a. As produced. b. After digestion reduce the volatile solids content by 50% and decrease the moisture content to 90%. c. After dewatering to 75% moisture. d. After dewatering to 10% moisture. e. After incineration (only nonvolatile solids remain) Solution: The mass of sludge is 1000/0.05 = 20 000 kg

A. 70% of solids are volatile = 0.7 * 1000 = 700 kg Specific gravity of volatile is 1.05 Volume of volatile solids = 700/(1.05* 1000) = 0.666 m3= 666 L 30% of solids nonvolatile = 0.3 * 1000 = 300 kg Specific gravity of nonvolatile = 2.5 Volume of volatile solids = 300/(2.5* 1000) = 0.12 m3 = 120 L. Volume of water= mass/density = (20 000 1000) / 1000 =19 m3 total volume of sludge = volume of volatile solids + volume of non volatile solids + volume of water Total volume of sludge= 666 + 120 + 19000 = 19786 L

B. After digestion, the volatile solids are reduced to 50 % (350 kg), the total solids content is therefore 650 kg (300 + 350). The total mass of sludge = 650 /(1- 0.9) =6500 kg Total volume of sludge = 333 +120 + 5850 = 6303 L C. After dewatering, the total mass is 6500/0.25 = 2600 kg. Total volume = 333 + 120 + 1950 = 2403 L D. After drying, the total mass is 650/0.9 = 722 kg And the volume is: 333 + 120 + 72 = 525 L E. After incineration only nonvolatile solids remain, the total mass is 300 kg and the volume = 300/ (2.5 *1000) = 0.12 m3= 120 L. A 100% B 32% C12% D 3% E 1%

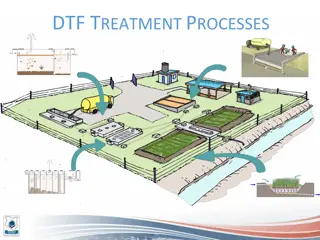

Sludge Treatment: 1. Thickening 2. Digestion 3. Dewatering (drying). Thickening: several techniques are available for volume reduction: a. gravity thickener: they are very similar in design and operation to the secondary clarifier used in suspended growth process. Gravity thickener should be able at least to double solids content (eliminate half the volume).

b. Flotation thickeners: using different air (air bubbles) to float suspended solids Used to thicken light sludge such as waste activated sludge. Waste activated sludge can be concentrated to approximately 4% solids by this technique. Retention time 30 minute to 1 hours. Digestion: It is the conversion of solids to noncellular end products. The goals of this process are reduce the volume of thickened sludge and convert the remaining solids to inert materials and relatively pathogen free.

a. anaerobic digestion It produces considerably less biomass than aerobic processes. Reactor for anaerobic digester consist of closed tank with airtight covers b. Aerobic digestion It is energy consumptive The digested sludge is relatively inert but dewaters poorly Simple operation and maintenance and low capital cost

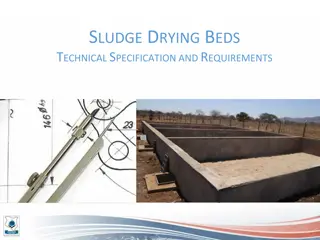

Dewatering (drying): Dewatering system range from outdoor sludge drying beds to extremely sophisticated mechanical systems such as vacuum filters. Drying beds: at least two beds should be provided even in small plants. Dewatering occurs as a result of drainage and evaporation and it is heavily dependent on climate. Area required varies according to climate and sludge characteristics. Times required range from several months to few weeks.