Project Cost Estimation for Microgrid Equipment and Installation

This module delves into estimating project costs for microgrid equipment, including procurement, installation, design, and engineering. It covers categories such as installation costs, design and engineering costs, overhead costs, and contingency costs, to provide a comprehensive understanding of estimating and budgeting for microgrid projects.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

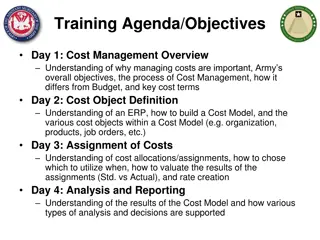

Module 11 -Cost Estimation This module covers how to estimate project costs including: Equipment costs combination of procurement and installation (including construction) costs associated with the microgrid equipment Design costs costs for A&E to perform a detailed design as well as a portion of the engineering analysis necessary to design a microgrid Engineering costs costs to do detailed engineering analysis of the performance and controls for the microgrid Overhead costs costs associated with other entities such as city or military personnel, regulatory agencies, etc. necessary to install the microgrid If overhead costs are not known, these costs are factored into the 25% contingency cost factor to estimate overall costs for a project 1

Elements of cost estimation To simplify the cost calculation, the cost components are broken down into the following categories: Installation Costs costs to procure and install all equipment involved in conceptual designs including construction firm overhead costs Cost for construction overhead for installation can be optionally be calculated separately from equipment procurement costs and then tabulated as long as this is done consistently throughout the estimation process Design and Engineering Costs costs for detailed A&E firm design plans, and engineering involved in installation, testing and final implementation of conceptual design. Estimated to be 25% of the total installation costs Contingency Costs Additional 25% contingency added to account for unanticipated costs associated with the conceptual design such as base or city planning related costs. Overall Construction Costs Sum of installation, design and engineering as well as contingency costs. Approximately 1.5X of installation costs If any of these costs are more directly known, for example design costs are $350K, from an estimate from an A&E firm, these costs can be substituted for this formula used to estimate these costs. 2

Installation costs Installation costs include the following cost components Distribution Infrastructure Costs Generator Costs Cyber Security and Controls Costs Retrofit Costs (if needed) CHP, PV and Energy Storage (if included) Labor for installation 3

Distribution infrastructure costs Distribution infrastructure costs are all costs associated with connecting clusters of buildings together using underground or overhead conductors. This includes: Cabling costs of conductors (overhead (OH) or underground (UG)) Trenching and Conduits trenching, duct bank and conduit costs for UG cables; OH conductors would be costed for pole structures Manholes access to buildings and connections for UG systems Transformers it may be necessary to install transformers to connect building loads to the microgrid if existing transformers cannot be used; transformers are also needed to step up voltages from generators to medium voltage levels 4

Generator costs Generator costs are all costs associated with providing N-1 redundant generation to individual buildings or clusters of buildings. This includes: Generators Natural gas, diesel, microturbines, fuel cells, etc. which supply the main energy source to the microgrid ATS Automatic transfer switches to connect and disconnect backup generators from critical building loads Parallel Switchgear In some cases more expensive parallel switchgear is required to connect multiple generators together Additional Fuel Storage Additional fuel tanks to supply diesel fuel to diesel engines for longer duration outages; can also use propane storage for natural gas engines; some engines are rated for other sources like JP or biofuels during emergency conditions 5

Retrofit costs Retrofit costs are all costs associated with upgrading building service equipment to meet the DBT, such as raising equipment for flood conditions. This includes: Relocation of Service equipment Switchboards, panelboards, transformers, and wiring to be above the DBT for the building New Equipment if equipment cannot be relocated, additional or duplicate equipment must be provided Demo/Restructuring Any costs associated with demolition and restructuring of the existing building structure in order to be able to supply power to meet the DBT 6

Example of retrofits Building Building electrical infrastructure Install additional Backup generation Raise equipment above flood zone Flood Zone

CHP, PV and energy storage costs CHP, renewables and energy storage are all costs associated with utilizing any of these opportunities with the conceptual designs to provide additional benefits. This includes: CHP combined cooling, heating and power; excess heat of building used to supply building heating and cooling relieving electrical requirements and making system more reliable Renewables use of renewables to offset generation use to reduce fuel requirements and emissions Energy Storage use of energy storage to provide non- interruptible power to certain loads or other applications such as smoothing PV and ramp rates of generators to make system more efficient 8

Example CHP benefit analysis Peak Electric Load (kW) Natural Gas Savings ($2013) CHP NG Costs ($2013) Installed System Cost ($2013) CHP Size (kW) Electric Savings ($2013) O&M Costs ($2013) Net Payback (Years) Savings ($2013) Location Bldg A 100 142.7 $70.6k $33.0k $73.9k $8.0k $21.7k $221.0k 11 37.5 56.4 $40.7k $16.7k $30.0k $6.1k $21.3k $81.0k 4 Bldg B Bldg C 15 20.7 $9.9k $5.6k $9.0k $1.5k $5.0k $27.0k 6 100 142.7 $62.6k $33.0k $75.2k $8.0k $12.4k $224.9k 19 Bldg D

Example PV benefit analysis Usable PV Output (kW) System Cost Energy Value Payback: (years) Service Bldg A Bldg B Bldg C Bldg D Bldg E 550 360 300 240 210 $2635k $1724k $1437k $1150k $1006k $156.6k $102.5k $85.4k $68.4k $59.8k 10.5 10.5 10.5 10.5 10.5

Cyber security and control costs Cyber security and control costs are all costs associated with providing cyber security and controls to individual buildings or clusters of buildings. This includes: Control infrastructure Costs to install communications infrastructure necessary for microgrid controls (including monitoring, cyber security and protection) Control Center Laptops, pagers, etc. with different levels of access to monitor and control microgrids Generator Controls Local as well as overall supervisory controls involved with synchronization, startup and outputs of generators and isolation devices System Protection Devices involved in detecting and clearing faults which may occur within microgrids 11

Microgrid Element Costs COST ESTIMATE WORKSHEET Equipment and Installation Costs ($K) Construction Overhead (20%) ($K) Design Overhead (12.5%) ( $K) Engineering Overhead (12.5%) ($K) Total Costs ($K) Total Costs with Contingency (25%) ($K) Equipment/Approach Pin and Sleeve Building rewiring Pin and sleeves Portable Generators 10 10 2 2 2.5 2.5 2.5 2.5 17 17 21.5 21.5 Cost 2 x Cost Individual Building Hardening Building rewiring Building Generators 10 2 2.5 2.5 17 21.5 Cost 2 x Cost Microgrids Controls Fiber Optic Communications Building rewiring Generators Trenching and Cable 100 20 25 25 170 215 50 10 20 6.25 13 6.25 13 72.50 146 90 100 Cost 182 2 x Cost 100/1000ft 50/1000 ft PV Installed Costs PPA 3.50/kW 0.12/kWhr Batteries Installed costs 4.25/kW CHP Installed costs MA Incentive 2.25/kW (0.75/kW) Fuel Storage 2/1000 gal 4/1000 gal 12

Example system Existing 3 Buildings 60 kW G Ga G Ga Utility Feeder #1 Connected kVA = 600 kVA Load (30%) = 180 kW One 60 kW backup generator A A 200 kVA Utility Feeder #2 B B 150 kVA Above DBT Below DBT C C 250 kVA 13

Example system load data Existing Transformer Rating (kVA) 200 150 250 600 Peak Load Estimate (30%) (kW) 60 45 75 180 Existing Backup Generator (kW) Below DBT Building A B C 60 60 N N Y Total 14

Example system with microgrid New System with 3-building Microgrid Connected kVA = 600 kVA Load (30%) = 180 kW Generation needed (N-1) = >240 kW New Microgrid 60 kW G Ga Utility Feeder #1 A MH 125 kW 200 kVA 200 kVA Gb Utility Feeder #2 Building B has 50 kW of PV Potential B MH 150 kVA 150 kVA Above DBT Below DBT Building C below DBT requires retrofitting C MH Additional 2 125 kW generators added to existing 60 kW generator in new microgrid Any generator fail minimum 185 kW supply 250 kVA 250 kVA Gc Gc 125 kW 15

Cost calculations for example microgrid per unit cost ($K) Equipment Units Cost ($K) 0.3 147.6 100.0 17.5 11.0 4.8 220.0 1200 2 3 3 3 50 1 360.0 295.2 300.0 52.5 33.0 240.0 220.0 1500.7 375.2 225.1 2101.0 Cables Generators Controls Transformers Manholes PV Retrofit Infrastructure Total Design/Engineering Contingency Total with contingency 16

Another example microgrid Utility Power 900 kW New Diesel Generation Substation Breaker Critical Building Loads Dedicated Microgrid Feeder (Existing Conduit) Breaker Tie to Storage Resources Other Loads 100 kW Solar PV Array 50 kW Microturbine 200 kW Diesel Generator 600 kWh Battery Storage System 17

Cost spreadsheet with engineering, design and contingency costs Equipment and Installation costs ($K) Constructio n OH (20%) ($K) Engineering OH (12.5%) ($K) Total Costs ($K) Total Costs with Contingency (25%) ($K) Design OH (12.5%) ($K) Equipment Microgrid Breaker 100.0 20.0 12.5 12.5 145.0 181.3 Underground Feeder 530.0 106.0 66.3 66.3 768.5 960.6 Microgrid Controls 375.0 75.0 46.9 46.9 543.8 679.7 Misc Equip 250.0 50.0 31.3 31.3 362.5 453.1 Total w/o Generation 1255.0 251.0 156.9 156.9 1819.8 2274.7 Generation 1600 kW New Generation 1200.0 240.0 150.0 150.0 1740.0 2280.0 Total w/generation 2455.0 491.0 306.9 306.9 3559.8 4554.7 18