Sustainable Value Chains: Building Capacity for Environmental Initiatives

Developing sustainable value chains requires adopting life cycle management approaches, interpreting results with SWOT analysis, and considering how environmental initiatives can enhance the value proposition. Guidelines are provided for assessing maturity levels, identifying areas for improvement, and brainstorming potential projects such as offering organic product lines and enhancing operational efficiencies.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

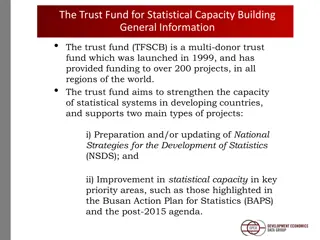

UNEP/SETAC Life-Cycle Initiative Life Cycle Management Capability Maturity Model (LCM-CMM) Building Capacity for Sustainable Value Chains International Life Cycle Partnership To bring science-based life cycle approaches into practice worldwide

DEVELOPING AN IMPROVEMENT PLAN

GUIDELINES Business context & priorities Maturity level determines scope Need for new procedure or methodology Need for standardization/ integration Maturity assessment helps target improvements to key areas Processes that deviate from average maturity identify gaps & strengths

SWOT MATRIX INTERNAL FACTORS Strength Weakness Positioning Org. Development Growth Opportunity EXTERNAL FACTORS Screening LCA to assess potential for organic cotton Develop procedures to support GHG, eco- labels Use strengths to take advantage of opportunities Overcome weaknesses by taking advantage of opportunities Positioning Org. Development Risk Mgmt. Develop supply chain environmental reporting Assess partners for green chemistry alternatives Threat Use strengths to avoid threats Minimize weakness and avoid threats

CAN ENVIRONMENTAL INITIATIVES ADD TO VALUE PROPOSITION? Costs- Do environmental drivers influence cost structure? Customer value- Are we in a position to communicate environmental benefits? Risk- Are we exposed or in a position to assume risk for a fee? Resources & capabilities- Are we in a position to leverage technical strengths? Market power- Are we in a position to exercise power to drive higher standards? Information- Are we in a position to control the flow? Do customers want environmental data?

BRAINSTORM POTENTIAL PROJECTS Offer organic product line Boiler efficiency upgrade Implement lean practices to increase inventory turns See companion Worksheet #7

PROJECT SELECTION Organizational Realities Impact Environmental and Financial Alignment with corporate strategy & goals Opportunity / Available resources Organizational development Build competency in critical skills Facilitate cross- functional integration Promote collaborations with external organizations Project Sponsor Go/ No Go Decision

IMPROVEMENT PLAN ID# Project Description Performance Improvement Target Organizational Development Objective Upgrade steam boiler system, insulate pipes 15% reduction in energy use; < 4 yr. payback Define procedure for GHG accounting 1 Install heat recovery on continuous wash line, monitor water use 20 % reduction in energy use; < 3 yr payback Develop formal energy mgmt program 2 Screening LCA of organic cotton 5% increase in margin; improve market share by 5% Draft eco- design guidelines for product engineering standards; Assess training needs Assess business oppty for organic product line 3 Meet near term quantitative performance targets Balanced with longer term organizational learning more reliance on process measures Delayed impact on effectiveness! See companion Worksheet #8

ACTION LEARNING WORKSHOP Hosted by business manager Facilitated by LCM champion Active learning Feedback from work outcome S W Accelerated implementation O T OPPTY ANALYSIS DETAILED DESIGN LIFE CYCLE MGMT CONCEPT VALIDATE DELIVER ACTIONABLE TASKS

ROLES & RESPONSIBILITIES Function Role Key information Environment, health & safety Hazard risk assessment, regulatory requirements Waste streams, injuries, hazards, regulatory trends, stakeholder expectations Engineering (IPD) Design of products & services Concept, design requirements, tools, technical standards Advanced Programs Product/ technology strategy Competitive analysis Facilities & operations Process capability, available services Baseline data, takt time, costs, process capability Finance Business case analysis Cost drivers, capital appropriation, value engineering Supply management Value chain analysis Make vs buy, variety analysis, supplier capability Sales & marketing Launch strategy Marketing trends, customer requirements, competitive data Customer support Aftermarket strategy Customer feedback, warranty Quality Continuous improvement Defect rates, root cause, MFA

PROJECT CHARTER Description of problem Why important to customer, organization Improvement goal Integration with other initiatives, measures of success Scope- boundaries, assumptions, constraints Schedule & resources Team membership Information gaps Reality check Go/ No Go criteria

EVENT CHECKLIST Workshop sponsor & LCM champion endorse charter Top level product system life cycle map completed Priority environmental and social themes identified (external perspective) Critical technologies and processes identified (internal perspective) Key functional group representatives identified EH&S technical support information gathered Event logistics Conference room Computer, A-V equipment, flip charts Food, breaks & other creature comforts Pre-event awareness training

PROCESS IMPROVEMENT KAIZEN Typical Agenda Day One Goals & objectives Training: Kaizen principles, process mapping, hazard identification Activity: Map process(es), identify inputs & outputs, hazards Day Two Training: Risk assessment, root cause analysis, brainstorming Activity- Rank & prioritize hazards, conduct root cause, brainstorm potential alternatives Day Three Training: Alternative selection process Activity: Investigate alternatives, implement quick fixes Day Four Training: Developing alternatives, financial analysis Activity: Complete alternatives assessment, apply cost accounting tool, project schedule Day Five Training: Ground rules for mgmt presentation Activity: Complete report to mgmt, complete quick fixes, Make final presentation to mgmt

PROCESSES AND SYSTEMS Outputs Inputs Process or System PPDP (Detail Level Map) PMT / IPT Engineering SUPPLIERS Configuration Management CUSTOMERS Producer Assy & Test Quality Feedback Feedback What is the purpose of this process? What are the key inputs? What must be accomplished to go to next step? Are there any unnecessary steps? Where are the problems? 13

DfE DESIGN CHARRETTE Typical Agenda Day One -AM Goals and objectives Training: DfE principles, Product requirements, life cycle analysis, hazard identification Activity: Map product system life cycle processes, identify & prioritize hazards Day One - PM Training: Risk assessment, root cause analysis, decision criteria, brainstorming Activity- Review & validate priority hazards, rank selection criteria, brainstorm potential alternatives Day Two- AM Activity: Continue brainstorming, investigate any information gaps Activity: Rank alternatives using pre- defined selection criteria Day Two- PM Training: Financial analysis, value proposition Activity: Develop action plan for detailed evaluation of alternatives

LINK PRODUCT ARCHITECTURE AND PROCESS DESIGN Product Design Process Design Sub-sys 1 Sub-sys 2 PPDP (Detail Level Map) PMT / IPT Engineering Sub-sys 3 Configuration Management Producer Assy & Test Quality What are functional requirements? Which performance criteria constrain process selection? Which performance criteria dictate materials selection? Which components or sub-systems drive cost and quality? 17