Copper Nickel Alloy 90/10 Secondary scrap

Copper Nickel 90/10 Scrap denotes the recyclable material originating from the Copper Nickel 90/10 alloy, comprising 90% copper and 10% nickel, alongside minor traces of other elements. This alloy is renowned for its exceptional resistance to corro

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

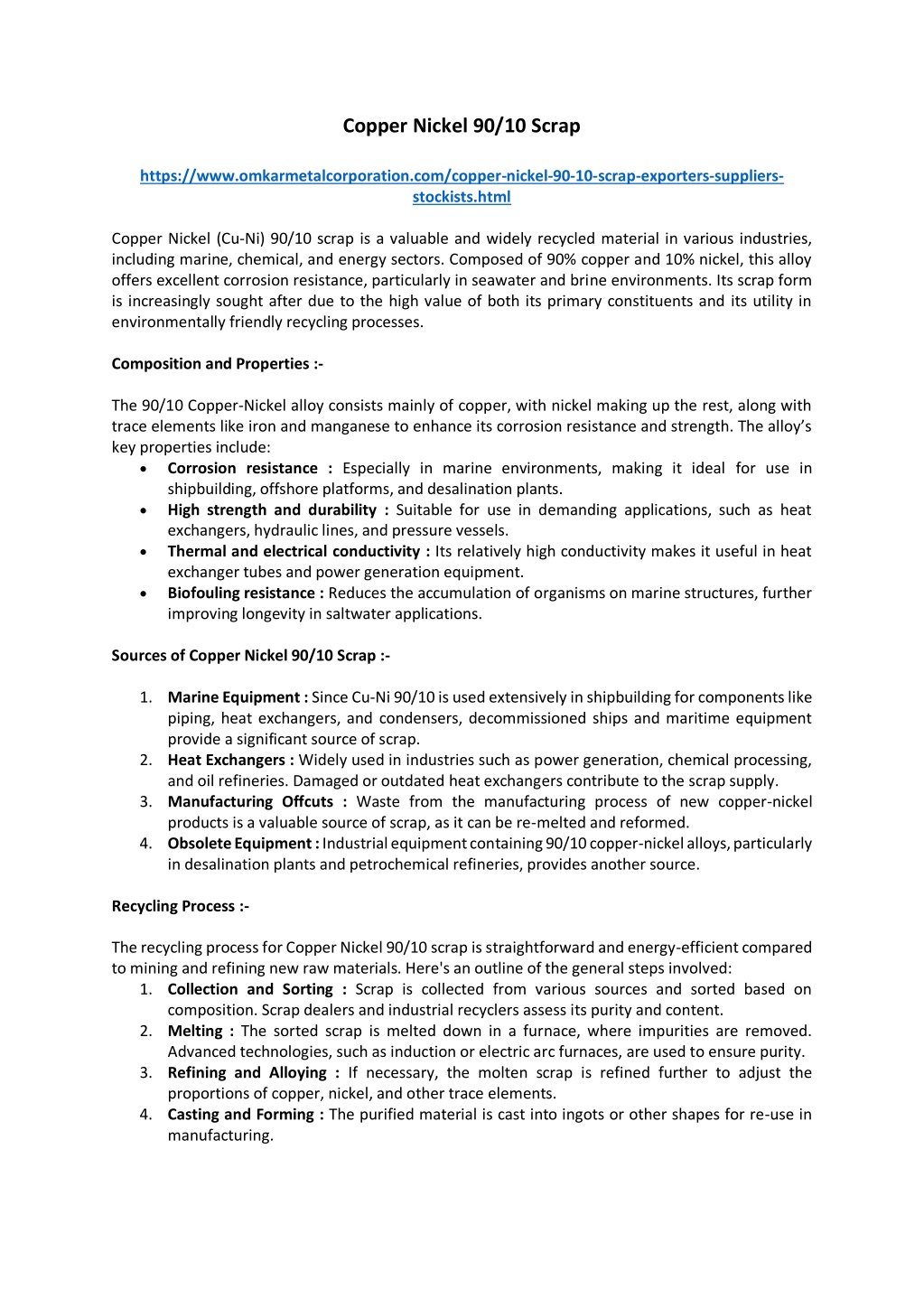

Copper Nickel 90/10 Scrap https://www.omkarmetalcorporation.com/copper-nickel-90-10-scrap-exporters-suppliers- stockists.html Copper Nickel (Cu-Ni) 90/10 scrap is a valuable and widely recycled material in various industries, including marine, chemical, and energy sectors. Composed of 90% copper and 10% nickel, this alloy offers excellent corrosion resistance, particularly in seawater and brine environments. Its scrap form is increasingly sought after due to the high value of both its primary constituents and its utility in environmentally friendly recycling processes. Composition and Properties :- The 90/10 Copper-Nickel alloy consists mainly of copper, with nickel making up the rest, along with trace elements like iron and manganese to enhance its corrosion resistance and strength. The alloy s key properties include: Corrosion resistance : Especially in marine environments, making it ideal for use in shipbuilding, offshore platforms, and desalination plants. High strength and durability : Suitable for use in demanding applications, such as heat exchangers, hydraulic lines, and pressure vessels. Thermal and electrical conductivity : Its relatively high conductivity makes it useful in heat exchanger tubes and power generation equipment. Biofouling resistance : Reduces the accumulation of organisms on marine structures, further improving longevity in saltwater applications. Sources of Copper Nickel 90/10 Scrap :- 1.Marine Equipment : Since Cu-Ni 90/10 is used extensively in shipbuilding for components like piping, heat exchangers, and condensers, decommissioned ships and maritime equipment provide a significant source of scrap. 2.Heat Exchangers : Widely used in industries such as power generation, chemical processing, and oil refineries. Damaged or outdated heat exchangers contribute to the scrap supply. 3.Manufacturing Offcuts : Waste from the manufacturing process of new copper-nickel products is a valuable source of scrap, as it can be re-melted and reformed. 4.Obsolete Equipment : Industrial equipment containing 90/10 copper-nickel alloys, particularly in desalination plants and petrochemical refineries, provides another source. Recycling Process :- The recycling process for Copper Nickel 90/10 scrap is straightforward and energy-efficient compared to mining and refining new raw materials. Here's an outline of the general steps involved: 1.Collection and Sorting : Scrap is collected from various sources and sorted based on composition. Scrap dealers and industrial recyclers assess its purity and content. 2.Melting : The sorted scrap is melted down in a furnace, where impurities are removed. Advanced technologies, such as induction or electric arc furnaces, are used to ensure purity. 3.Refining and Alloying : If necessary, the molten scrap is refined further to adjust the proportions of copper, nickel, and other trace elements. 4.Casting and Forming : The purified material is cast into ingots or other shapes for re-use in manufacturing.

Applications of Recycled Copper Nickel 90/10 :- Recycled Copper Nickel 90/10 scrap is re-used in several industries, often in the same applications as the original material : Marine Engineering : Pipes, heat exchangers, and valves used in seawater environments. Desalination Plants : Condensers and heat exchangers for handling high-salinity fluids. Chemical Processing : Equipment in chemical plants that need to withstand corrosive environments. Energy Production : Heat exchangers and power generation equipment. Copper Nickel Alloy Scrap Buyer, Copper Nickel Alloy 90/10 Secondary Stocks, Copper Nickel Alloy 90/10 Excess Stock, Copper Nickel Alloy Flat Bar Cut Lengths. We Are Buyer Of Copper Nickel Alloy Sheet Cuttings, Copper Nickel Alloy 90/10 Round Bar Cut Lengths, Copper Nickel Alloy 90/10 rejected Stocks, Copper Nickel Alloy Plate Cuttings, Copper Nickel Alloy 90/10 Secondary scrap purchaser, Copper Nickel Alloy 90/10 processed Secondary scrap, Copper Nickel Alloy 90/10 resources recovery, Copper Nickel Alloy 90/10 Secondary scrap prices, Copper Nickel Alloy 90/10 Secondary scrap, Copper Nickel Alloy 90/10 Secondary scrap buyer, Copper Nickel Alloy 90/10 Secondary scrap purchase Specification Of Copper Nickel 90/10 SCRAP :- Grade Cupro Nickel 90/10 Type Recyclable Thickness Condition 2mm-10mm Waste Scrap Types Turnings, Shavings, Plate Cuts, Round Cuts, Shaftings, Pipe Cuts Condition of Supply Loose Bales, Compressed Bales, Pillow Bales, Bulk, Capsules, Side slits For More Details Contact Us : 91-9320777636 If any enquiries please contact us our support team will connect you as soon as possible.