Exploring Alternatives to Plastic Pollution

Discovering cheaper and more durable alternatives to plastic is crucial in combating global pollution. Educating the masses about the impact of plastic usage and introducing innovative solutions like using chicken feathers and liquid wood can help reduce plastic waste significantly.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Plastic Plastic

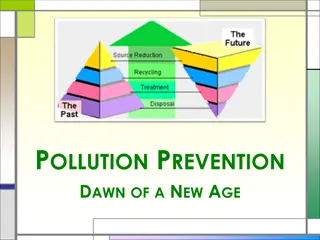

Knowing alternatives- since the excessive usage of plastic has caused major plastic pollution around the world, people should look for it's alternatives. Existing alternatives- there are a lot of existing alternatives but they haven't come into practice because they are too expensive and also some are not as durable as plastic. The crowd will not buy expensive alternatives. Cheaper and durable alternatives should be made for a large part of the mass to use it.

Convincing the mass- if you want the plastic usage and pollution to be in control or minimal, it is very important to educate the mass about it, because in the case of India, the literacy rate varies from State to state, Kerala having the highest- 93.91% and Bihar having the lowest- 63.82%. Know about the global plastic pollution- Many countries in the world produce huge amount of plastic waste and contribute to the global pollution. Countries like China, Indonesia, Philippines,vitenam and Sri Lanka are the largest producer and consumer of plastic.

During primary and secondary research, it was observed and concluded that people are not willing to opt for alternatives of plastic because either it is more expensive and has high manufacturing cost or the alternatives are not as durable as plastic. So the main area of concern of our project is finding cheaper alternatives to plastic or reducing the manufacturing cost of existing alternatives. We are keen to work on existing alternatives to make it more durable so it can replace plastic in most of the industries.

Chicken Feathers The United States found out that disposing of chicken feathers is a problem, but with the help of innovation, they can be a material useful to make a water-resistant thermoplastic. Chicken feathers are consist of keratin, a tough and durable protein like plastics. It can be found in hair and wool. The keratin-based plastic is proven to be more resistant to tearing than other plastics made from soy, starch, and other agricultural sources. It is cost-effective, renewable, and fully biodegradable.

Liquid Wood Liquid wood looks, feels and acts like plastics but unlike petroleum-based plastic, this is biodegradable and suitable for various product packaging. Some researchers use this as substitute to make toys, golf tees, and hi-fi speaker boxes. PCL Polyesters Polycaprolactone is a synthetic aliphatic polyester that s not created from renewable resources but could degrade after weeks of composting. The process is easy, but it is seldom used because of its manufacturing costs.

PLA Polyesters Polylactic acid (PLA) is an aliphatic polyester and can be made from lactic acid. PLA can also be created from wheat or sugarcane. It has the ability to decompose within forty-seven days in an industrial composting site, and it would not release toxic fumes when burned. It is open to new packaging applications for green plastic, automotive parts, and coffee cups.

PHA Polyesters Polyhydroxyalkanoate (PHA) polyesters are biodegradable plastics that resemble with man-made polypropylene. They are less flexible than petroleum-based plastics, and useful in in plastic films, injection-molded bottles, and packaging.

EG Bags Joining the ranks of nature's crusaders is a 25- year-old native from Mangalore who has designed an ingenious substitute for the ubiquitous plastic bags - one that can be deceptive at first glance. When submerged in warm water ,it begins to dissipate - contrary to plastic bags that do not react this way since it contains chemical additives. These bags degrade naturally when discarded and cause no harm to animals if they consume it and are completely non toxic to enviornment.

Plastic From Seeweed Indonesian start-up Evoware is working with bioplastics: a line of fully biodegradable plastics made from seaweed. Evoware teamed up with local seaweed farmers to come up bioplastics. The company chose seaweed because it dissolves in water and leaves behind zero waste, is 100 percent biodegradable and can act as a natural fertilizer for plants, and can be grown with minimal resources. Evoware has even come up with edible-grade

Bioplastics to replace the plastic packaging being used for food wrappers. In addition to being completely edible,this bioplastics has been touted as highly nutritious and rich in fiber, vitamins, and minerals. These bioplastics are tasteless, odorless, and can last for as long as two years if kept sealed in their original packaging.

Plastic From Milk To create an all-around better packaging solution, Tomasula and colleagues at the U.S. Department of Agriculture are developing an environmentally friendly film made of the milk protein casein. These casein-based films are up to 500 times better than plastics at keeping oxygen away from food and, because they are derived from milk, are biodegradable, sustainable and edible.

Although the researchers first attempt using pure casein resulted in a strong and effective oxygen blocker, it was relatively hard to handle and would dissolve in water too quickly. They made some improvements by incorporating citrus pectin into the blend to make the packaging even stronger, as well as more resistant to humidity and high temperatures.

1 - EnviGreen Bags Eg bags are made of Potato, tapioca, corn, natural starch, vegetable oil, banana, and flower oil. Despite all the organic materials used in making Eg bags, GYLCEROL can be added in making, as a plasticizer (produce or promote plasticity and flexibility and to reduce brittleness). Glycerol is produced by the fermentation of sugar, or from vegetable and animal oils and fats.

It is a material that makes the polymer chain molecules bend and slide past each other more easily, which adds to the flexibility of the plastic. In expensive Effective

2 - Bio-plastic from Seaweed The term bioplastic represents a plastic substance that is based on organic biomass rather Than petroleum. Seaweed production does not require any agricultural land or fresh water, and all its biomass can be used. The purpose of Seaweed for food is to create a sustainable source of healthy food Products, additives and feed by means of cultivation in the Dutch waters.

- How to maximise seaweed value? Multiple processing of seaweed to ensure all are optimally used at the highest possible economic value. Making seaweed products more appealing to consumers by developing attractive product and accessible information. Reducing the use of antibiotics and applicants for the pharmaceutical industries.

- What does bio-plastic mean? It basically means a substance was derived from plastic-based material. Starch and cellulose are two of the most common renewable feedstocks used to create bioplastics; these typically come from corn and sugarcane.

- What are the benefits of bio- plastic? The greatest advantages of bioplastic industry are a smaller energy footprint and a less polluted ecosystem. Bioplastics are gaining popularity because they don t contain bisphenol A, as this element has been used in many food products which is very harmful for humans, hence edible bio-plastic is much more beneficial in this case.

3. Plastic with milk Plastic was made by adding vinegar to the milk and then separating the liquid and semi liquid materials and giving the semi liquid material a shape and letting it freeze. Instead of this we can add a STARCH to it which will increase it s consistency. Starch becomes soluble in water when heated. The granules swell and burst, the semi-crystalline structure is lost and the smaller amylase molecules start leaching out of the granule, forming a network that holds water and increasing the mixture's viscosity. https://www.youtube.com/watch?v=OQsI_c3F23s

This will help the structure to be stiff and remain in the same way. Also, all the materials are edible including starch and it can be called an edible plastic with more research.

Presented by: Ritika Shah Sakshi J Shah Punya Harikumar Nancy Khilwani Ayushi Monpora