Wire Nail Making Machine

A wire nail-making machine efficiently produces high-quality nails from metal wire. It automates cutting, shaping, and head formation, ensuring uniform size and strength. Ideal for industrial use, this machine increases production speed and precision, reducing labor costs while maintaining consistent nail standards for construction and manufacturing applications. For more information visit our website: ASVR MACHINE //

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

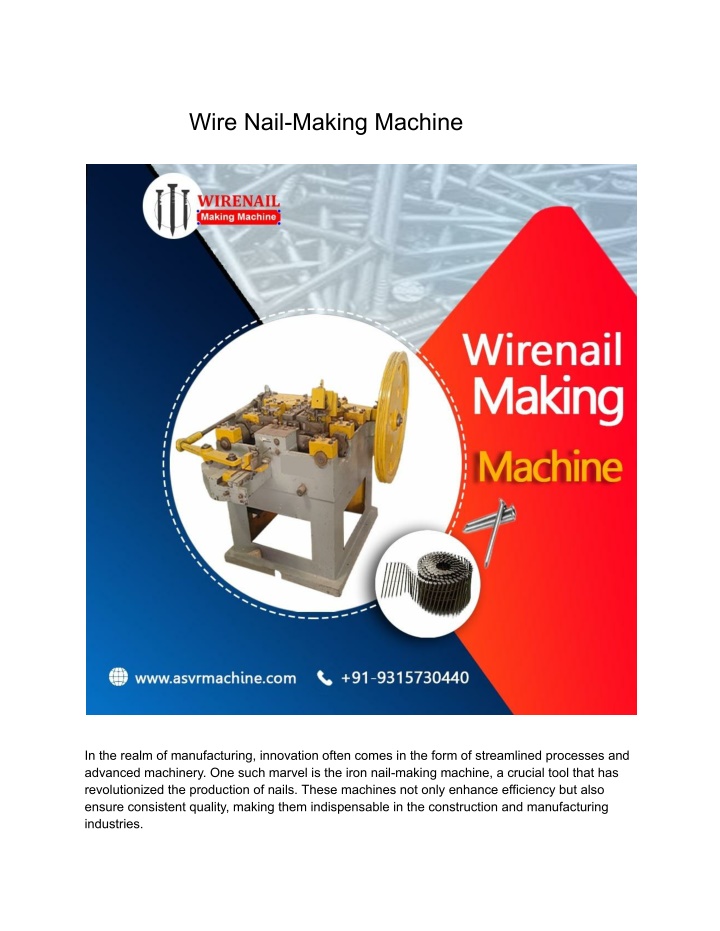

Wire Nail-Making Machine In the realm of manufacturing, innovation often comes in the form of streamlined processes and advanced machinery. One such marvel is the iron nail-making machine, a crucial tool that has revolutionized the production of nails. These machines not only enhance efficiency but also ensure consistent quality, making them indispensable in the construction and manufacturing industries.

The Evolution of Nail Manufacturing Historically, nails were handcrafted by blacksmiths, a labor-intensive process that limited production capacity and consistency. With the advent of the Industrial Revolution, mechanization began transforming industries, and nail production was no exception. Early nail-making machines mechanized part of the process, but modern steel nail-making machines represent a pinnacle of efficiency and automation. How Iron Nail-Making Machines Work A wire nail-making machine is a highly specialized equipment designed to convert wire into nails of various sizes and shapes. The process typically involves several key steps: Feeding: Wire is fed into the machine from a coil. The machine straightens the wire as it is drawn in. Cutting: The wire is cut into predetermined lengths corresponding to the desired nail size. Head Formation: The cut wire pieces are then moved to the heading section where the nail heads are formed. This is achieved through a series of dies and punches. Point Formation: The nails are then pointed at one end to facilitate their intended use. Polishing: The finished nails often go through a polishing stage to ensure smooth surfaces and remove any burrs. Advantages of Modern Wire Nail-Making Machines Efficiency and Speed Modern iron nail-making machines can produce thousands of nails per minute, starkly contrasting to manual or semi-automated processes. This high-speed production capability is essential for meeting the demands of large-scale construction projects and industrial applications. Consistency and Quality Automation ensures that each nail produced meets exact specifications, reducing variability and ensuring consistent quality. This is crucial for construction purposes where materials' uniformity can significantly impact a structure's integrity. Versatility These machines can be adjusted to produce nails of various sizes and types, including common nails, roofing nails, and specialty nails. This versatility makes them suitable for a wide range of applications. Cost-Effectiveness While the initial investment in a iron nail-making machine can be significant, the long-term benefits include reduced labor costs and increased production rates, leading to overall cost savings.

Technological Advancements Recent advancements in iron nail-making machines include the integration of digital controls and monitoring systems. These features allow for precise control over the production process, real-time monitoring of machine performance, and immediate troubleshooting of issues, thereby minimizing downtime. Environmental Impact Modern steel nail-making machines are also designed with energy efficiency in mind. Enhanced energy management systems and the use of sustainable materials in their construction contribute to reduced environmental impact. Additionally, these machines generate minimal waste, as any excess material from the wire can often be recycled within the production process. Applications in Various Industries The primary application of wire nail-making machines is in the construction industry, where they are essential for producing nails used in building frameworks, roofing, and finishing works. However, their utility extends to other sectors such as furniture manufacturing, packaging, and even automotive industries, where specific types of nails are required. Conclusion The wire nail-making machine stands as a testament to the power of industrial innovation. By combining speed, efficiency, and precision, these machines have transformed the way nails are manufactured, driving progress across multiple industries. As technology continues to evolve, we can anticipate further enhancements in nail-making processes, contributing to even greater efficiencies and higher standards of quality in manufacturing.