Why Is It Advised To Choose On Site Mix Concrete For Your Site Work

Unsure about concrete for your construction site? Explore the benefits of on-site mixed concrete - cost-effective, fresh, and customizable. Learn why it might be the perfect solution!

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

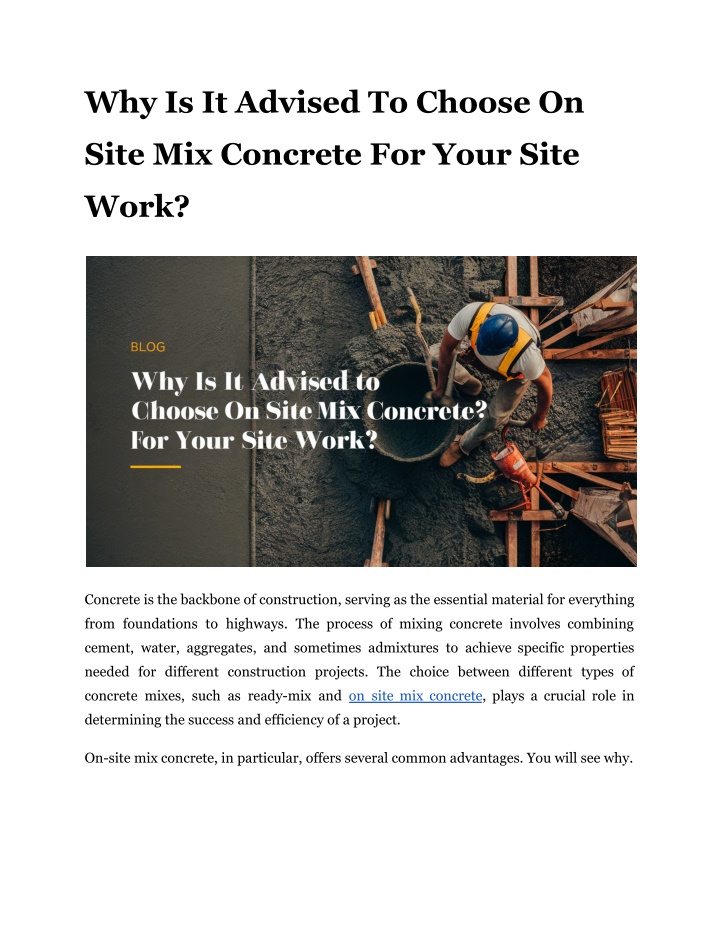

Why Is It Advised To Choose On Site Mix Concrete For Your Site Work? Concrete is the backbone of construction, serving as the essential material for everything from foundations to highways. The process of mixing concrete involves combining cement, water, aggregates, and sometimes admixtures to achieve specific properties needed for different construction projects. The choice between different types of concrete mixes, such as ready-mix and on site mix concrete, plays a crucial role in determining the success and efficiency of a project. On-site mix concrete, in particular, offers several common advantages. You will see why.

Advantages of On-Site Mix Concrete Cost Efficiency On-site mix concrete can be more cost-effective for smaller projects primarily because it eliminates the need to purchase large volumes of concrete in advance. This is particularly beneficial for small-scale or sporadic projects where the exact amount of concrete needed can vary. By mixing concrete on-site, you only use the exact quantity required, which reduces material waste and avoids the cost associated with excess concrete that would otherwise need to be discarded. This method not only saves money but also reduces the financial burden of overordering. Read More Articles: Revealing the Secrets: The Allure of the Smoking Mystery Box Flexibility and Customisation One of the standout advantages of on-site mix concrete is its unparalleled flexibility. This method allows for the mixing of small or large batches of concrete as needed, which can be particularly useful for projects with varying requirements. The mix design can be adjusted on-site to meet immediate project demands. Search up mix on site concrete near me and see just how many companies pop up promising exactly this. This ability to customise the mix on the fly ensures that the concrete produced meets the exact specifications needed for each unique application, providing a tailored solution that ready-mix concrete cannot offer. Reduced Waste On-site mixing significantly minimises waste by producing only the amount of concrete that is needed at any given time. This not only helps in managing project costs but also contributes to environmental sustainability. Plus, on-site mixing lessens the overall environmental impact of the construction project by avoiding overproduction and reducing the disposal of excess material. This approach is particularly advantageous in

terms of resource efficiency and aligns with sustainable construction practices aimed at reducing the carbon footprint of building activities. Quality Control of Your On Site Mix Concrete On-site mix concrete offers superior control over the quality of the mix by allowing for real-time adjustments to the proportions and materials. This flexibility ensures that the specific requirements of each project can be met with precision. When concrete is mixed on-site, skilled laborers can monitor and modify the mix as needed, ensuring the correct ratios of water, cement, aggregates, and any necessary admixtures. This hands-on approach helps in maintaining the desired properties such as strength, durability, and workability. The potential for higher quality control is significantly enhanced with on-site mixing. Skilled personnel can continuously check and test the mix, making immediate corrections if any deviations are detected. This proactive quality management reduces the likelihood of defects and inconsistencies, leading to a more reliable and durable final product. Logistics and Storage Benefits One of the key logistical advantages of on-site mix concrete is the reduction in complexity. Since the materials are brought to the site and mixed as needed, there is no requirement for the large-scale storage of pre-mixed concrete. This not only simplifies the logistics but also frees up valuable space on-site that would otherwise be occupied by ready-mix deliveries and storage silos. On-site mixing also eliminates the dependency on timely deliveries from a central plant, which can be particularly beneficial in remote or congested areas where transportation might be challenging. When you search for mix on-site concrete near me and have a good company come mix your concrete on-site, construction teams can avoid delays caused by traffic, road conditions, or scheduling conflicts with the concrete supplier. This ensures a more consistent workflow and helps in maintaining project timelines.

Additionally, the need for extensive storage facilities is minimised. Raw materials such as cement, aggregates, and admixtures can be stored in smaller, more manageable quantities, reducing the footprint on the construction site and making it easier to organise and manage materials efficiently Enhanced Innovation and Customisation Innovative Additives One of the main benefits of on-site mixing is the flexibility it offers to introduce and adjust additives during the mixing process. This adaptability is crucial for achieving desired properties such as enhanced strength, durability, workability, and reduced setting times. For instance, air-entraining admixtures introduce tiny, stable air bubbles into the concrete mix, improving its workability and resistance to freeze-thaw cycles. This is particularly beneficial in climates with extreme temperature variations. Accelerating admixtures are used to speed up the setting time, which is useful in colder weather conditions or when early strength is required. Conversely, retarding admixtures slows down the setting process, allowing for longer working times, which is advantageous in hot climates or for complex pours. Another example is the use of super-plasticizers, which significantly reduce the water content in the mix without compromising its workability. This results in higher-strength concrete with enhanced durability. Self-healing concrete is another innovative material that can be integrated into on-site mixes. It contains special additives that react with water and carbon dioxide to heal cracks automatically, extending the lifespan of the concrete. Read More Articles: Do Salesforce Consulting Partners Provide Ongoing Support and Maintenance After Implementation

Custom Design Features On-site mixed concrete also allows for unparalleled customisation in architectural designs and unique features. Contractors can create bespoke concrete that meets the specific aesthetic and structural requirements of a project. This flexibility is particularly advantageous for complex and detailed designs that might not be achievable with pre-mixed concrete. A notable example of this customisation is the use of decorative concrete. Incorporating coloured aggregates, dyes, and surface treatments produce visually appealing concrete surfaces that mimic the look of natural stone, tile, or even wood. Exposed aggregate finishes, where the top layer of concrete is removed to reveal the underlying aggregates, are another popular design feature that can be easily achieved with on-site mixing. Get Your On Site Mix Concrete From The Best Suppliers Integrating these benefits, your construction projects can achieve superior performance and aesthetic appeal. For the best on-site mix concrete services, look no further than Pro-Mix Concrete. When you search "mix on site concrete near me," we stand out for our commitment to quality, reliability, and customer satisfaction. Trust Pro-Mix Concrete to deliver the perfect mix for your project every time, ensuring the highest standards in the industry. Site Article: Why Is It Advised To Choose On Site Mix Concrete For Your Site Work?