The Importance of Correct Mix Ratios in C35 Concrete for Structural Integrity

Learn why accurate mix ratios in C35 concrete are crucial for structural integrity. Ensure safety and durability in your construction projects.n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

The Importance of Correct Mix Ratios in C35 Concrete for Structural Integrity Concrete is the main building material used in construction projects all over the world. It's strong, long-lasting, and can be shaped into many forms. One special type of concrete is called C35 concrete. Known for its superior strength and durability, C35 is particularly suited for structural applications where higher load-bearing capacity is required. What is C35 Concrete? It is a specific grade of concrete. The "C" stands for "Concrete," and the number "35" refers to its strength. This strength is measured by how much pressure the concrete can handle without breaking. C35 can withstand 35 Newton per square millimeter (N/mm ) or 35 megapascals (MPa) of pressure after 28 days of curing (drying and hardening). This type of concrete is often used in buildings, bridges, and other structures that need to be very strong. It's stronger than regular concrete used in simpler projects like sidewalks or driveways.

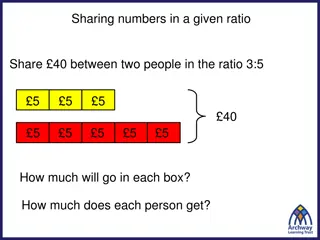

The Basic Ingredients of C35 Concrete C35 is made by mixing several ingredients: 1. Cement: This is the "glue" that holds everything together. It reacts with water to bind the other materials. 2. Water: When mixed with cement, it starts a chemical reaction that makes the concrete harden. 3. Fine aggregates: These are small particles like sand. 4. Coarse aggregates: These are larger particles like gravel or crushed stone. 5. Sometimes, special additives are included to give the concrete certain properties, like making it dry faster or being more water-resistant. The Importance of Correct Mix Ratios Getting the right mix of these ingredients is super important. If you use too much or too little of something, the final product won't turn out right. In concrete, the wrong mix can lead to weak or crumbly concrete that can't do its job properly. Here are some reasons why the correct mix ratio is crucial: 1. Strength: The right mix ensures the concrete reaches its intended strength. Too much water, for example, can make the concrete weak. 2. Durability: Proper ratios help the concrete last longer and resist wear and tear. 3. Workability: The correct mix makes the concrete easier to pour and shape before it hardens. 4. Cost-effectiveness: Using the right amounts of each ingredient avoids waste and keeps costs down. 5. Safety: Strong, properly mixed concrete is safer and less likely to fail in a building or structure. Read More Articles: Cybersecurity 101 - Protecting yourself and Your Company from Internet Threats The Standard Mix Ratio While the exact mix can vary slightly depending on the specific project and local materials, a typical c35 concrete mix ratio might look like this: 1. Cement: 1 part 2. Fine aggregate (sand): 2 parts 3. Coarse aggregate (gravel): 3 parts

4. Water: 0.45 parts (compared to the amount of cement) This is often written as a ratio of 1:2:3:0.45. Remember, these are parts by weight, not volume. The water-to-cement ratio (w/c ratio) is particularly important. For C35, it's usually around 0.45. This means for every 1 kg of cement, you use 0.45 kg of water. How Mix Ratios Affect Concrete Properties Different mix ratios can change how the concrete behaves both when it's wet and after it hardens. Let's look at how each main ingredient affects the concrete: 1. Cement: More cement generally makes stronger concrete. However, too much cement can lead to cracking as the concrete dries. It's also the most expensive ingredient, so using too much raises costs. 2. Water: More water makes the concrete easier to pour and work with. But too much water weakens the concrete and can lead to cracking and shrinking as it dries. Not enough water makes the concrete hard to work with and may not allow the cement to react properly. 3. Fine aggregates (sand): Help fill in small spaces and make the concrete smoother. Too much can make the concrete hard to work with and reduce strength. Too little can make the concrete porous and weak. 4. Coarse aggregates (gravel): Provide the main bulk and strength of the concrete. Too much can make the concrete rough and hard to work with. Too little can lead to more shrinkage and cracking. The Role of Water in C35 Concrete Water plays a special role in concrete mixing. It starts the chemical reaction that makes cement harden, a process called hydration. The right amount of water is crucial: Too little water: The cement won't fully hydrate, leaving the concrete weak. Too much water: The concrete will be easier to pour but will end up weaker and more prone to cracking.

The water-to-cement ratio for concrete (usually around 0.45) is carefully chosen to provide enough water for full hydration while maintaining strength. Testing the Mix Before using C35 in a big project, it's important to test it. This usually involves making small samples of the concrete mix and testing them after they've cured for 28 days. The tests check things like: 1. Compressive strength: How much pressure the concrete can handle before breaking. 2. Slump test: This checks how workable the wet concrete is. 3. Air content: Too much or too little air in the concrete can affect its strength and durability. If the tests show that the concrete isn't meeting the C35 standards, the mix ratio might need to be adjusted. Common Problems from Incorrect Mix Ratios Using the wrong mix ratios can lead to several problems: 1. Low strength: If the concrete isn't strong enough, it might not be able to support the weight it needs to hold. 2. Cracking: Too much water or cement can lead to cracks as the concrete dries. 3. Shrinkage: Concrete naturally shrinks a bit as it dries, but too much shrinkage can cause problems. 4. Poor workability: If the mix is too dry, it can be hard to pour and shape. 5. Segregation: This happens when the different ingredients separate, usually because there's too much water. 6. Bleeding: This is when water rises to the surface of the concrete, which can weaken the top layer. 7. Porosity: If the mix is too dry or doesn't have enough fine aggregates, the concrete can end up with too many tiny holes, making it weak and prone to water damage. Factors That Can Affect the C35 Concrete Mix Ratio While there's a standard mix ratio, sometimes it needs to be adjusted. Here are some reasons why:

1. Local materials: The exact properties of cement, sand, and gravel can vary from place to place. 2. Weather conditions: Hot, cold, or humid weather can affect how the concrete behaves. 3. How the concrete will be used: Some projects might need concrete that's easier to pour, while others might prioritise quick drying. 4. Equipment available: The type of mixing and pouring equipment can influence the best mix ratio. 5. Transportation time: If the concrete needs to travel a long way before being poured, the mix might need adjusting. 6. Special requirements: Some projects water-resistant or that can set quickly. might need concrete that's extra The Mixing Process Getting the right mix ratio is important, but so is the mixing process itself. Here's a basic outline of how C35 concrete is usually mixed: 1. Measure ingredients carefully, usually by weight. 2. Add coarse aggregates to the mixer. 3. Add fine aggregates. 4. Add cement. 5. Start the mixer and blend dry ingredients. 6. Slowly add water while mixing continues. 7. Mix for several minutes until the concrete is uniform. It's important to mix thoroughly to ensure all the ingredients are evenly distributed. Read More Articles: Is Your Cybersecurity Putting Your Business at Risk? Pouring and Curing C35 Concrete Once the concrete is mixed, it needs to be poured quickly. C35 usually stays workable for about 30-60 minutes, depending on the temperature and humidity. After pouring, the concrete needs to be cured. This is the process where the concrete hardens and gains strength. Proper curing is crucial for reaching the full strength of C35 concrete: 1. Keep the concrete moist for at least 7 days. This can be done by spraying it with water or covering it with wet burlap.

2. Protect it from extreme temperatures. Very hot or cold weather can affect how the concrete cures. 3. Allow it to cure for at least 28 days before subjecting it to full loads. The Importance of Quality Control Because the mix ratio is so important for C35, quality control is crucial. This involves: 1. Careful measurement of all ingredients. 2. Regular testing of the concrete mix. 3. Proper training for all workers involved in mixing and pouring. 4. Keeping detailed records of each batch of concrete. 5. Having a plan for what to do if a batch doesn't meet standards. Good quality control helps ensure that every batch of C35 is up to standard and will perform as expected in the finished structure. Environmental Considerations The production of cement, a key ingredient in concrete, has a significant environmental impact due to CO2 emissions. Some ways to make C35 concrete more environmentally friendly include: 1. Using supplementary cementitious materials like fly ash or slag to partially replace cement. 2. Optimising the mix design to use cement more efficiently. 3. Using recycled aggregates where possible. 4. Ensuring proper quality control to avoid waste from batches that don't meet standards. Conclusion As building techniques and materials science advance, we might see new ways to improve C35 concrete or alternatives that perform even better. But for now, understanding and correctly using mix ratios remains a fundamental skill for anyone working with this important building material. Transform your construction projects with Pro-Mix Concrete s top-quality C35 mix. Our durable, high-strength concrete ensures your structures stand the test of time. Contact our c35 concrete suppliers today to get the best concrete solution for your needs!

Site Article: The Importance of Correct Mix Ratios in C35 Concrete for Structural Integrity