Understanding Secondary Clarifiers in Wastewater Treatment

Secondary clarifiers play a crucial role in wastewater treatment processes by producing clarified effluent and concentrating biological solids. This involves settling tanks following trickling filters and suspended growth processes, each with specific objectives. Column and continuous flow analyses help optimize the performance of secondary clarifiers by measuring solid flux and settling characteristics. A practical example demonstrates how to calculate solids flux and determine clarifier size based on influent concentration and flow rate.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

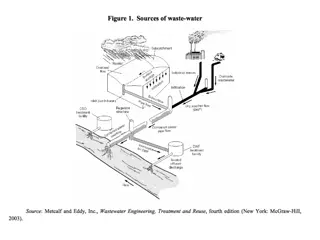

1. Secondary clarifier following trickling filter: The function of settling tank that follow trickling filter is to produce a clarified effluent. They differ from activated sludge settling tank is that the clarifier has a much lower suspended solid content and sludge recirculation is not necessary. 2. Suspended growth process clarifier: Secondary clarifier in this process must accomplish two objectives: a. They must produce a clarified effluent to meet discharge standards. b. They must concentrate the biological solids to minimize the quantity of sludge that must be handled.

Column analysis: If a column is filled with a concentrated suspension and allowed to settle quiescently, the contents will soon divided into zones as shown in figure below:

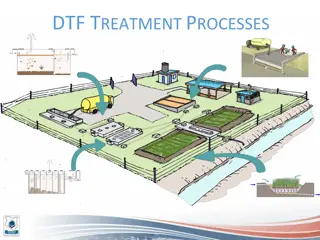

Continuous flow analysis: The zones settling described for batch analysis are applicable within limits to secondary clarifier. Solid flux: is defined as the mass of solids per unit time passing through a unit area perpendicular to the direction of flow: Solid flux (kg/ m2hour) = solid concentration (kg/m3) X velocity (m/hr) Solid flux has two components: 1. Solid flux due to withdrawal of sludge. 2. Solid flux due to gravity settling.

Ex. A column analysis was run to determine the settling characteristics of an activated sludge suspension, the results of the analysis are shown in the table below: Concentration (mg/L) 1400 2200 3000 3700 4500 5200 6500 8200 Velocity (m/hr) 3 1.85 1.21 0.76 0.45 0.28 0.13 0.089 The influent concnetration of of (MLSS) is 3000 mg/L and the flow rate is 8000 m3 /day , determine the size of the clarifier that will thicken the solids to 10 000 mg/L.

Solution: 1. Calculate the solids flux from the above data: G = MLSS (kg/m3) X velocity (m/hr) Concentration (mg/L) 1400 2200 3000 3700 4500 5200 6500 8200 G (km/ m 2hr) 4.2 4.07 3.63 2.8 2.03 1.46 0.9 0.73 2. Plot solids flux vs MLSS concentration as shown in the figure

5 4 3 2 1 0 0 2000 4000 6000 8000 10000

3. Determine total solids loading to the clarifier: 8000 X (1/24) X3 = 1000 kg/hr. 4. Determine the surface area of the clarifier 1000 /2.4 = 416.7 m2 Assuming circular shape Diameter: 23 m 5. Check clarification function: 8000 X (1/24) = 333 m3 /hr. at 3000 mg/L. the settling velocity is 1.21 m/hr = 333/ 1.21 = 275 m2 A = Q/Vs