Trickling Filter: A Sustainable Wastewater Treatment Solution

The trickling filter is a biological treatment process utilizing a solid media where bacteria accumulate to maintain high populations. Bacteria growth occurs on the media surface with oxygen provided by air diffusion. As bacteria metabolize waste, they reproduce, creating a biological layer. Filter classification includes low-rate and high-rate trickling filters based on organic loading rates. Distribution systems involve rotary distributors or fixed nozzles for uniform wastewater flow. Trickling filters remove 65-85% of BODS and suspended solids from sewage through biological slime growth, enhancing wastewater treatment efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

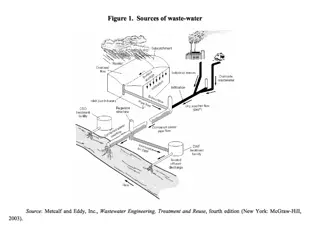

This process utilize a solid media upon which bacteria solids are accumulated, in order to maintain a high population. Trickling filter utilize a relatively porous media such as rock or plastic material or wood.

Bacteria growth occurs upon the surface while oxygen is provided by air diffusion through the void spaces. The wastewater is applied to the surface usually in an intermittent fashion and percolates through the filter.

As metabolize the waste they will reproduce gradually producing biological layer, the bacteria in the interiors layer find themselves in a nutrient limited situation since the organic matter and oxygen are utilized. the bacteria on the filter surface thickening of the

Filter classification Low rate trickling filter: The organic loafing rate range from 0.3 to 1.5 kg/ cubic meter. High rate trickling filter: Organic load 1.5 19 kg/ cubic meter. Employing recirculation of wastewater around the filter.

Distribution system There are two types of distribution system 1. rotary distributors: consist of a hollow arm pivoted at center fitted with nozzel which provide a uniform flow / unit area. 2. fixed nozzel: it is less expensive than rotary distributors and they are located so as to ensure reasonably uniform distribution of wastewater.

5.8.2 Trickling Filter The trickling filter is an established biological treatment process removing 65 to 85% BODS and suspended solids. The process consists of a bed of highly permeable medium. An overhead rotating distributor applies sewage to the media. The flow trickles over and flows downward to the underdrain system. The media provides a large surface area to develop biological slime growth which is also known as zoogleal film. The film contains living organisms that break down organic material in the sewage. Many variations of the trickling filters have been constructed, however the recom- mended designs are given in Table 5.12. 5.8.3 Design Requirements for Trickling Filters Secondary screens and flow balancing tanks to equalise the flow must be provided before trickling filters. Provisions shall be available for even distribution to achieve complete wetting of the filter media. 9 of 34

5.8.4 Sequencing Batch Reactors (SBR) Sequencing Batch Reactors are suspended activated sludge systems where flow of sewage into a reactor, biological oxidation, and clarification of the sewage take place within the same reactor on an alternative sequence of cyclical mode. There are five (5) basic sequences in a cycle, namely: 1. Fill 2. React (Aeration) 3. Settle 4. Decant 5. Iddle SBR plants typically consist of a minimum of two (2) reactors in a plant. When one unit of reactors is in, the fill mode, the other reactor(s) may be in the stage of react, settle, decant or iddle. 11 of 34

Flow Diagram 5.8 : SBR Operation 12 of 34

Figure 5.9 : Flow Diagram of Bandar Tun Razak STP Screen Pit (Existing Pumping Station) Outfall Grit Chamber Sequential Measuring Equalization Batch Reactor Tank Tank Tank Screening, Grits Waste and Oil sludge Mechanical Thickener Supernatant Filtrate Disposal Sludge Dewatering 13 of 34

MLVSS is the volatile portion of the MLSS and ranges from 0.75 to 0.85. Typically they are related, for design purposes, by MLVSS = 0.80 MLSS. 5.12 Trickling Filter The trickling filter is the most commonly used unit of the fixed-growth film-flow type process. A trickling filter consists of a bed of coarse material, such as stone slates or plastic media, over which wastewater from primary effluent is sprayed. The underdrain is used to carry wastewater passing through the biological filter and drain to the subsequent treatment unit and to provide ventilation of the filter and maintenance of the aerobic condition. Wastewater from the primary effluent is distributed to the surface of the filter bed by fixed spray nozzles or rotary distributors. 14 of 24

Biological slime occurs on the surface of the support media while oxygen is supplied by air diffusion through the void spaces. It allows wastewater to trickle downward through the bed media. Organic and inorganic nutrients are extracted from the liquod film by the icroorganism in the slime. The biological activity of the trickling filter process can be described as shown below. 15 of 24

16 of 24

The microbial layer on the filter is aerobic usually to a depth of only 0.1 ~ 0.2mm. Most of the depth of the microbial film is anaerobic. Almost all trickling filters constructed in the late 1980s have been of high rate media type. Plastic media have become popular. The depth of plastic media range from 4 to 12m. NRC formula. The NRC (National Research Council) formula for trickling-filter performance is an empirical expression developed by the National Research Council from an extensive study of the operating data of trickling treatment plants at military bases within the United States during World War II in the early 1940s (NRC 1946). The equation for a single-stage or first-stage rock filter is E1 = 100 (SI units) 1 + 0.532 W/VF 17 of 24

Where efficiency of BOD removal for first stage at 20oC E1 = including recirculation and sedimentation, % W = BOD loading to filter, kg/d = flow times influent concentration volume of filter media, m3 V = F = recirculation factor 18 of

The recirculation factor is calculated by F = 1 + r (1 + 0.1r)2 Where r = recirculation ratio, Qr/Q recirculation flow, m3/d Qr = wastewater flow, m3/d Q = 19 of

The recirculation factor represents the average number of passes of the influent organic matter through the trickling filter. For the second-stage filter, the formula becomes E2 = 100 (SI units) 0.0532 W1 1 E1 VF 1 + Where E2 = efficiency of BOD5 removal for second-stage filter, % W1 = BOD loading applied to second-stage filter, kg/d Other terms are as described previously. Overall BOD removal efficiency of a two-stage filter system can be computed by 1 - 35 1 - E1 1 - E2 E = 100 100 100 100 100 20 of

Where the term 35 means that 35 percent of BOD of raw wastewater is removed by primary settling. BOD removal efficiency in biological treatment process is significantly influenced by wastewater temperature. The effect of temperature can be calculated as ET = E20 1.035T-20 Formulation for plastic media. Numerous investigations have undertaken to predict the performance of plastic media in the trickling filter process. The Eckenfelder formula (1963) and the Germain (1965) applied Schulze formulation (1960) are the ones most commonly used to describe the performance of plastic media packed trickling filters. 21 of 24

Eckenfelder formula. Eckenfelder (1963) and Eckenfelder and Barnhart (1963) developed an exponential formula based on the rate of waste removal for a pseudo-first-order reaction, as below : 1 + m Se/Si = exp - KAs D/qn Where Se = effluent soluble BOD5, mg/L Si = influent soluble BOD5, mg/L K = observed reaction rate constant, m/d or ft/d As = = surface area/volume, m2/m3 or ft2/ft3 specific surface area D = depth of media, m or ft q = = Q/A influent volumetric flow rate influent flow, m3/d or ft3/d Q = cross-sectional area of filter, m2 or ft2 A = m,n = empirical constants based on filter media 22 of 24

Also may be simplified to the following form :- Se/Si = exp - kD/qn where k is a new rate constant, per day 23 of

The mean time of contact t of wastewater with the filter media is related to the filter depth, the hydraulic loading rate, and the nature of the filter packing. The relationship is expressed as t = C = C D qn (Q/A)n an d C ~ 1/Dm Where t = mean detention time C, n = constants related to the specific surface and configuration of the packing 24 of 24