Understanding Fuels and Their Classification

Fuels are combustible substances that serve as a source of heat or raw material for various industries. They can be classified as natural or artificial, solid, liquid, or gaseous, and primary or secondary fuels. Primary fuels like coal and wood are directly used for heat, while secondary fuels are manufactured from primary fuels. Fuels can be of organic (vegetable) or inorganic (mineral) origin and are essential for energy production in domestic and industrial settings.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

UNIT V FUELS

Fuels are naturally occurring(fossil fuel) or artificially manufactured combustible organic substances which is a source of heat or raw material for industry. Fuel is a substance that undergoes combination with O2in air to liberate heat. They can be solids, liquids or gases.

They have carbon and hydrogen. The chief fuels are coal and mineral oil. Fuels can be either of vegetable (organic- coal etc) or mineral (inorganic sulphur, iron pyrites etc) origin, can be also nuclear, like enriched uranium oxide.

Definition 1. Defined as any source of heat energy. 2. It is a combustible substance containing carbon as main constituent which on proper burning gives large amount of heat that can be used economically for domestic and industrial purposes. 3. It is any chemical or any reactant which produces energy in a form that can be used for producing power.

Classification Fuels are classified as follows I: Solid, liquid and gases II: i) Natural or raw fuels or primary fuels. Ex: Wood Peat, coal, petroleum ii) Manufactured or processed or artificial or secondary fuels Ex: Coke, charcoal, kerosene, petrol

III : i) Primary fuels ii) Secondary fuels Primary fuels are directly used for the function of heat and its technical utilization as such. They may be solids, liquids or gases. Ex: Coal, wood, petroleum.

Secondary fuels are one from which other fuels are manufactured, which is then utilized as fuel. These are obtained from primary fuels. Ex Coal gas, water gas, producer gas etc are obtained from primary fuel coal.

Natural fuels: Solid Fuels Ex; Wood, peat, lignite, bituminous, anthracite coal Liquid Ex: petroleum Gaseous Natural gas from petroleum wells.

Manufactured fuels Solid: Charcoal, high and low temperature coke. Liquid Petrol or gasoline, kerosene, diesel, ethanol, methanol Gaseous: Coal gas, coke oven gas, producer gas, water gas.

Industrial fuels: I : Power generating fuels : These are burned in power plants for generating energy. II : Process fuels: These are used in industrial furnaces and driers to produce heat which is needed in various industrial processes.

Calorific value : The amount of heat given out by different fuels will be different. This difference is compared based on calorific value. Calorific value is defined as the amount of heat produced in calories during the combustion of one gram of a substance in oxygen. Its unit is kcalg-1.

Calorific value is measured by the number of British thermal units (BTU) liberated by the combustion of one lb of a solid fuel or one cubic feet of a gaseous fuel. 1 BTU is the amount o heat required to raise the temperature of one lb of water through 1oF. Calorific value can be measured using bomb calorimeter.

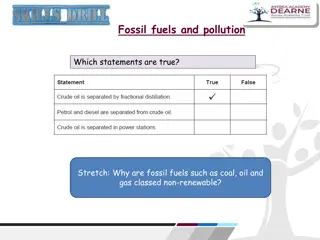

Flash point: For a liquid fuel it is the temperature at which it emits vapour which is kindled by a flame. The lowest temperature, at which oil continues to burn after a flame has been applied to it, is its ignition point. Flash point of gasoline is 45oC, for kerosene it is 73oF.

Ignition temperature: It is the temperature below which a solid fuel will not catch fire and burn.

Essential requirements of fuels: A good fuel should have high calorific value and low moisture content. It should be of low cost and readily available. It should be easily transportable. It should not give any undesirable by products during burning. It should leave only little ash or non- combustible material. If they have large percentage of non- combustible material left as ash then the calorific value decreases.

The combustion product of the fuel must not be harmful. It should burn in air with efficiency without producing much smoke. Its combustion should take place spontaneously and should be controllable. Particle size of solid fuels should be uniform.

It should produce high temperature, called as pyrometric burning effect. This highest temperature obtained by combustion depends upon i) calorific value ii) Velocity of combustion iii) space in which it is burnt iv) physical state of fuel. If same quantity of solid, liquid and gaseous fuels is burnt in same amount of air, gaseous fuel gives the highest pyrometric effect, liquid less effect and solid the least.

Fuels should have proper ignition point. If have low ignition temperature then fire hazards can happen. But high ignition temperature makes fuel safe for transportation and storage, but not favorable for starting fire. So moderate ignition temperature and moderate velocity of combustion is favored for a good fuel.

Energy characteristics of a fuel: Energy characteristics of a fuel depends on Heat of combustion: It is the amount of heat obtained by burning a unit mass or volume of a fuel. Energy content : It is the amount of potential heat energy contained in a unit volume of a fuel and measured as the volume of fuel in m3 corresponding to one ton of reference fuel, whose heat of combustion is 292.4kj/kg(700kcal/kg)

Solid and liquid fuels contain organic combustible part(C,H,O) and a mineral in combustible part which is moisture and inorganic compounds like silicates, phosphates, sulphates, sulphites of metals like Ca, Al, Fe, K and Na. These mineral substances are converted into metal oxides on burning of solid fuel and remaining ash.

Sulphur as sulphides is oxidized to SO2. Moisture and minerals lower the energy ratings of fuels, raise the cost of transportation and complicates processing technology. When fuel is heated without access of air (pyrolysis) gaseous and liquid products from that are contained as vapours in the pyrolysis products. This vapour and gas mixture also containing the fuel water is called volatile matter.

Water Gas: Water gas is often called as blue gas since the flame formed will be blue in colour when burnt. Water gas is a mixture of CO and H2. It is produced by passing steam over red hot bed of coke at 1400 to 1000 0C.

H2O + C CO + H2 This is an endothermic reaction, so temperature falls from 1400 to 10000C. At this temperature CO2is also formed. 2H2O + C 2H2+ CO2 -29 kcal. -19 kcal

This CO2has no calorific value. Formation of water gas depends on the decomposition of steam by coke at 758oC, at this temperature 25.3% steam is decomposed so the composition will be 56.2% of H2, 7.8% CO and 27%CO2. At 1000oC 93% stem is decomposed so the composition will be 50.7% H2, 48%CO and 1.3% CO2.

And at 1125oC 99.4% of steam is decomposed so the composition will be50.9%H2, 48.5% CO and 0.6%CO2. To maintain the percentage of decomposition ie at 1000oC or above, blast of steam is stopped and air blast is passed to raise the temperature to 1400oC.

Then pass stem blast and then pass air blast and so on. Since air forms explosion with water gas, water gas is removed by passing steam for one minute, this steam is called purge steam. The average composition of water gas is 48% of H2, 1% of CH4, 42% of CO, 3% of CO2and6% of N2. The calorific value of water gas is about 300 Btu/cu ft.

Uses: Used as a source of H2and as a reducing agent in metallurgy. It is added to coal gas for street lighting. Used to synthesis chemicals like alcohols and oxygenated compounds.

Producer Gas: Producer gas is a mixture of CO and N2. This a cheap individual fuel obtained from low grade coal. This is prepared by passing air over a bed of white hot coke or solid carbonaceous fuel at 1000 1400oC. C + O2+ 2N2 (air) CO + 2N2 H = -27.06kcal

During preparation, actually CO2is first produced; it then reacts with coke to give CO. Instead of coke and coal, peat, wood waste, spent tar can be used. But largely used raw material is coke and coal. Coke or anthrasite or charcoal is used if producer gas is used in gas engines for power production. It is manufactured in a plant known as gas producer .

The fuel is stacked in a grate in the cylindrical furnace, made of fire clay refractory bricks. The blast of air is blown through the grate. The fuel is fed from the top. Gas produced leaves the furnace through the gas outlet. 2C + O2 2CO + 58000 cal C + O2 CO2 +97000 cal CO2+ C 2CO -39000 cal

The CO2formed is reduced to CO by heated coke and as the reaction is endothermic, the temperature of the bed is kept high at above 1000oC. The proportion of CO increases with increase in temperature.

Producer gas has lower calorific (1300kcal/m3) value of any gaseous fuel and the temperature of its flame is the lower of any fuel. Its calorific value is 150Btu per cubic feet. Its average composition is 10% H2, 8% CH4,20% CO, 4%CO2and 64% N2.

Uses: It is used for heating coal gas retorts, in furnace and gas engines.

Oil Gas: This oil is used in labs. It is obtained by cracking heavy oil like kerosene, during which a mixture of gaseous hydrocarbons are produced. C16H34 6CH4+ 2C2H4+ C2H2+ 4C The average composition of oil gas is 25-30% CH4,50-55%H2,10-12%CO and 3%CO2 . Its calorific value is 4500-5400kcal/m3.

Natural gas: This is a mixture of methane (80- 98 %), ethane, propane, butanes, pentanes, CO2, N2 etc. Its calorific value is 1200-1400kcal/m3. This is found in vicinity of coal mines or oil fields.

It is used in domestic, industrial and as a chemical raw material for various syntheses. It accumulates in underground reservoirs either with or with out petroleum oil. Natural oils obtained from oil wells may be either wet or dry.

i) Dry Variety This type contains mainly of methane and does not contain either gasoline vapour or crude petroleum. Its composition will be 96%CH4, 0.8%C2H4and 3.2%N2.

ii) Wet variety This type consists of a mixture of methane and higher HC, like n-propane, n-butane. Isobutene, isopentane etc. It is obtained from oil producing wells along with petroleum. Calorific value of this variety is higher than dry variety because of its high percentage of heavier unsaturated molecules.

By products from natural gases: The products formed like methane, ethane, propane, butane, natural gasoline and LPG are of industrial importance. These are separated from crude gas as liquids by the absorption of higher HC in petroleum or catalytically polymerizing higher HC into liquid HC. Natural gas is transported in the form of liquid.

The gas contains undesirable compounds like H2O, H2S, which should be removed before usage. The gas obtained by fermentation of organic matter in sewage is also called sewage natural gas. The sewage is collected and subjected to anaerobic fermentation, were by the nitrogenous matter in it is converted into nitrates and a part of the carbonaceous matter is converted into sewage natural gas consisting mainly of methane and CO2.

This gas contains 70% methane and 30%CO2. The calorific value of the gas is 62.5Btu/Cu ft.

Cow dung is the main source of natural gas. Cow dung on fermentation gives gas with composition as in sewage gas. The residue formed in this process is used as manure. Natural gas burns with smoky flame in ordinary burners. So use special appliances.

Natural gas can be liquefied under pressure and cooling to -121oC. This can be mixed with other fuels to increase their calorific value. This gas is used for the manufacture of carbon black.CH4natural gas used for the manufacture of formaldehyde and methanol by controlled oxidation. Helium is also recovered from natural gas.

Coal gas: Coal gas is obtained from the destruction of coal ie when coal is heated in the absence of air. One ton of coal gives12000cubic feet of coal gas at 1000oC and the yield is 18%.The yield can be increased to 22% by increasing the temperature to 1400 -1500oC.

Coal gas produced by this process is a mixture of gases and about 95% of it is combustible. The compounds present in the mixture depend on the temperature of carbonization. The average composition of the gas is 49% of H2, 32% of CH4, 8% of CO,4-5% acetylene and ethylene, 4% of N2, 1% of O2and 1% of CO2.

H2, CH4and CO are non-illuminating but heat producing, N2, O2and CO2are inert or diluents. H2S, CS2, NH3, cyanogens etc are present as impurities. Its calorific value is about 4900kcal/m3.

This gas is used to provide inert atmosphere in number of preparations, used to provide reducing atmosphere in metallurgical operations, in smelting of metals and alloys, used as fuel and illuminanent, used in producing fuel gases and in making graphite, and does not condense on cooling.

Gobar or bio gas: This is a mixture of methane, CO2, H2and H2S. The average composition is 55% CH4, 7.4% H2, 35%CO2, 2.6%N2and traces of water. This is produced by the anaerobic fermentation of animal waste in the absence of O2and in the presence of H2O.

The carbohydrates, proteins and fats in animal waste are broken down by bacteria to form CH4. The residue formed during the process can be used as manure since the essential nutrients like N2and phosphorous remains intact.

The gas is highly flammable and is used as fuel. Natural gas is also biogas, which results from long time decay of animal and vegetable matters brought about by bacteria s at high temperature, high pressure etc. The average calorific value is 5300kcal/m3.