Understanding Concrete Durability in Extreme Climates

Discover how concrete withstands extreme weather. Learn tips to improve durability for long-lasting structures.n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

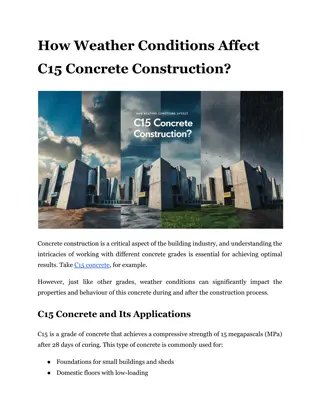

Understanding Concrete Durability in Extreme Climates Concrete is essential for modern construction, yet when exposed to extreme climates, its durability can be severely compromised. From scorching heat to cold, diverse environments present unique challenges that influence how concrete performs and ages over time. Engineers, architects, and builders often prioritise understanding these effects to ensure concrete structures endure. How Environmental Factors Affect Concrete Durability Extreme climates introduce a variety of conditions that can stress concrete, including temperature fluctuations, humidity, and chemical exposure. Each factor plays a distinct role in concrete s ability to resist deterioration over time. Temperature Extremes Temperature extremes affect concrete in notable ways: High Temperatures: In hot climates, high temperatures accelerate hydration, which can lead to faster initial strength gain but may reduce long-term strength.

Rapid water evaporation in high heat can result in shrinkage cracks, affecting structural integrity. Low Temperatures: In cold climates, low temperatures slow down hydration, delaying strength development. Repeated freeze-thaw cycles can cause internal cracking and surface scaling as water within the concrete expands and contracts. Humidity and Moisture Humidity levels also affect concrete s durability in extreme climates: High Humidity: Slows down evaporation during the curing phase, potentially causing segregation. Low Humidity: Increases the risk of plastic shrinkage, leading to surface cracks. Fluctuating Humidity: Frequent changes in moisture can cause concrete to expand and contract, leading to internal stress and cracking. Chemical Exposure Concrete in extreme environments is often exposed to aggressive chemicals: Marine Environments: Saltwater exposure can introduce chlorides that corrode the reinforcing steel within concrete. Industrial Areas: Sulfates and other industrial chemicals can degrade concrete over time. Urban Environments: CO in urban air can lower concrete s pH, accelerating corrosion of reinforcement. Mechanisms of Concrete Deterioration Understanding how deterioration occurs can help in designing concrete structures better suited for extreme climates. Below are some key mechanisms: Carbonation: When CO in the air reacts with calcium hydroxide in concrete, it lowers the pH, making the steel reinforcement vulnerable to corrosion. Chloride Ingress: Chloride ions can penetrate concrete and initiate steel corrosion, especially in coastal and marine areas. Freeze-Thaw Damage: Water expands when it freezes, causing internal stress that can crack or scale concrete surfaces.

Alkali-Silica Reaction (ASR): When reactive aggregates in concrete react with alkalis, an expansive gel forms, leading to cracking. Strategies for Enhancing Concrete Durability To address these challenges, several design and construction practices can be employed to enhance concrete durability in extreme climates. Here s a breakdown of key strategies: Optimising Mix Design Selecting the right mix is fundamental to improving durability in harsh climates: Low Water-Cement Ratio: A low ratio reduces concrete permeability, limiting the penetration of harmful substances and increasing resistance to chemical attacks. Supplementary Cementitious Materials (SCMs): Using materials like fly ash, slag, or silica fume in the mix can improve resistance to chloride and sulfate attacks. Proper Aggregate Selection: Non-reactive aggregates are essential for preventing ASR, while frost-resistant aggregates are recommended for areas prone to freeze-thaw cycles. Use of Admixtures Adding specific admixtures to the concrete mix can significantly enhance durability: Air-Entraining Admixtures: These create tiny air bubbles within the concrete, improving resistance to freeze-thaw damage. Corrosion Inhibitors: Used in areas with high chloride exposure, these admixtures protect the steel reinforcement from corrosion. Construction Practices Proper construction practices are just as important as mix design for ensuring concrete longevity: Adequate Curing: Proper curing helps concrete develop strength and reduces permeability. This can involve using curing compounds or wet burlap to maintain moisture. Temperature Control: To prevent thermal cracking, ice or chilled water can be used in hot climates, while insulation is beneficial in cold weather.

Reinforcement Cover: Ensuring adequate cover over reinforcement provides extra protection against chloride ingress and carbonation. Surface Treatments Protective treatments applied to concrete surfaces can add a layer of defense against harsh conditions: Sealers and Coatings: These form a barrier that can reduce chloride ingress and carbonation, extending concrete s life. Hydrophobic Impregnation: This treatment repels water while allowing the concrete to breathe, making it especially effective in wet environments. Maintenance and Monitoring for Long-Term Durability Maintenance is crucial for ensuring concrete performs as expected over its lifespan. Here are some important considerations: Non-Destructive Testing: Techniques like ultrasonic testing allow for regular inspection of concrete s internal condition without causing damage. Timely Repairs: Addressing minor damage early can prevent it from escalating, especially in extreme climates. Cathodic Protection: In severely corrosive environments, this technique can protect steel reinforcement by using a secondary metal that corrodes instead of the steel. Emerging Technologies for Durable Concrete Innovative technologies offer exciting possibilities for creating concrete that better withstands extreme climates: Self-Healing Concrete: Integrating materials like bacteria or polymers that can heal small cracks can reduce maintenance and enhance durability. Nano-Engineered Concrete: Using nanomaterials in the mix can improve both strength and durability, potentially making concrete more resistant to environmental stresses. Climate Adaptation Modeling: Predictive models that account for changing environmental conditions can help engineers design more resilient structures. Understanding the Role of Ready Mix Concrete

Ready-mixed concrete is a pre-mixed solution manufactured in a batching plant and then delivered to the construction site. This type of concrete is not only convenient but also allows for more consistent quality control compared to on-site mixing. Using ready-mix concrete in extreme climates can offer several advantages: Precision in Mix Design: Because it s mixed in a controlled environment, a ready mix can be tailored to include specific admixtures and supplementary materials, enhancing durability. Time Efficiency: Reducing on-site mixing time allows construction teams to complete projects faster, which is particularly advantageous in climates where extreme weather may interrupt construction. Conclusion Concrete durability in extreme climates is achievable by understanding and mitigating the environmental factors that affect it. By optimising mix design, using appropriate admixtures, and adhering to proper construction and maintenance practices, structures can be better protected against temperature extremes, humidity fluctuations, and chemical exposure. Additionally, innovative technologies and materials like ready-mix concrete tailored for specific climates can further extend concrete s lifespan, making it a more reliable and sustainable building material. Site Article: Understanding Concrete Durability in Extreme Climates