Understanding Bubble Size Distribution Using Magnetic Particle Tracking

Explore the methodology of determining bubble size distribution in fluid beds through Magnetic Particle Tracking (MPT). Learn about MPT key features, information obtained from 3D trajectory data, and the application of MPT for characterizing fluidized solids behavior. The usage of magnetic tracers and external magnetic field sensors, combined with sophisticated algorithms, allows for the visualization of bubble dynamics and coalescence dynamics. This cutting-edge technology provides valuable quantitative spatial and temporal information essential for process modeling and validation.

- Bubble Size Distribution

- Magnetic Particle Tracking

- Fluidized Solids

- Tracer Particles

- Process Modeling

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

A Method to Determine Bubble Size A Method to Determine Bubble Size Distribution with Distribution with Magnetic Particle Tracking Magnetic Particle Tracking Jack Halow Separation Design Group Waynesburg, PA Presented at the 2016 NETL Multiphase Workshop August 9-10, 2016 Morgantown, WV

Objectives Develop a methed to determine bubble size distribution with Magnetic particle Tracking (MPT) Acquire data sets to show a proof of concept Apply MPTS to develop statistically significant measures that characterize fluidized solids behavior and bubble size distribution Acquire data sets that can be used for validation of first principles, two phase, low order and process models.

What is MPTS A method using magnetic tracers and external magnetic field sensors to measure motion in fluid beds Tracer particles are constructed by inserting a tiny neodymium magnet into a lower density particle Single tracer particle injected into bed that follows the motion of solids Magnetic field signals from tracer sampled and recorded Algorithms de-convolute signals to give 3D trajectory Trajectory data analyzed to characterize solids motion 090701T03vector.pdw 2.0 mm glass beads 6.5 cm deep bed 85 LPM 6 5 4 Z 3 2 1 -1.0 -0.5 0.0 0.5 1.0 0 Y 1.0 0.5 0.0 -0.5 -1.0 X

MPTS Key Features Ridged but adjustable stand to accurately position field sensors Helmholtz coils to shape and control external magnetic field in the test volume NI16 bit interface and Lab View Software to acquire and log data High quality shielding to reduce noise Algorithms to filter data and further reduce noise Mass flow meter and multiple valves to accurately control and measure flow

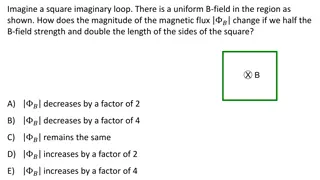

Information we get from MPTS 3D trajectory data Visualize tracer motion Position versus time graphs 3D vector plots Visualize average position Dot clouds 3D or 2D slicesa Quantitative spatial information Frequency distributions i.e. Weibull Fit to statistical models Quantitative temporal information Autocorrelation or FFT Bubble size distribution Overall and versus bed height Determine bubble coalescence dynamics Bubble size Bubble size 107_177 glass beads 107_177 glass beads 100 (U-Umf)/Umf 0.7 1.2 1.5 2.0 35.6-8.21*x 67.9-11.2*x 82.4-12.5*x 105.6-15.9*x 80 Events in 300 seconds 60 40 20 0 0 1 2 3 4 5 6 7 Db - cm

Tracer Rotation Key to Bubble Sizes Tracer in quiet bed Tracer orientation has magnetic axis vertical parallel to external field Bubbles induce shear at the interface with emulsion phase Other shear events less significant Tracer Disturbed by bubble Shear imposes a torque on tracer causing it to rotate Imposed vertical field from earth s magnetic field and Helmholtz coils resists this rotation If tracers center of gravity is not at geometric center, gravity also affects rotation

Torque on the Tracer from Bed Shear Use Faxen s Law from Laminar Theory: Only Gradient perpendicular to magnetic axis matters and fluid is not rotating. So:

What is Gradient and Viscosity? Velocity gradient: 0 dV U = z b d dt tra Viscosity (Grace 1970):

Magnetic torque Interaction of magnet with external magnetic field: H Maximum torque at 90 degrees n

Torque Balance Or Where

Bubble Velocity Using V=0.71(gDb)1/2 to eliminate Db Velocity is relative to tracer, need to subtract U-Umf

All Parameters are Known = frontal angle of bubble at 200 to 240 Lmg = length of magnet p = magnet field strength at pole surface |H| = external magnetic field strength p = particle density mf =void fraction at minimum fluidization dtra = tracer diameter Us = superficial velocity Umf = minimum fluidization velocity

Gravitational Torque If magnet is not centered in tracer, the offset center of mass will produce a torque Gravitational torque contribution can be calculated, but small size makes this difficult Torque from Fluidized Bed Better approach is to determine in fluid bed by finding external field that offsets gravity and lets tracer to freely rotate Magnetic torque Gravity

Experiments 5.5 cm bed with porous plate distributor Settled bed depth of 11 cm (H/D=2) Glass beads 107-177 micron 177-250 micron Us up to 2Umf 300 sec runs External field varied from 0 to 6x earth field Determine number of <90 degree rotations or events (to match force balance) in run

Rotations Vary with External Field External Field Controls Rotations External Field Controls Rotations 177 - 250 micon glass beads 177 - 250 micon glass beads 70 Earth's Vertical Field 60 Flow Rate 12..2 lpm 14.3 lpm 19.4 lpm 50 Events in 300 sec 40 30 20 10 0 -1500 -1000 -500 0 500 Vertical Field - milli-Gauss

Results for 107-177 Glass Beads 100 (U-Umf)/Umf 0.7 1.2 1.5 2.0 35.6-8.21*x 67.9-11.2*x 82.4-12.5*x 105.6-15.9*x 80 Events in 300 seconds 60 40 20 0 0 1 2 3 4 5 6 7 Bubbles>Db - cm

Results for 177-250 Glass Beads 100 (U-Umf)/Umf 80 0.3 0.6 1.1 58.4-10.9*Db 77.9-15.3*Db 116.3-19.8*Db Events (300 sec) 60 40 20 0 0 1 2 3 4 5 6 7 Bubbles > Db - cm

Bubble Frequency 16 107-177 Glass Beads 107-177 Glass Beads d(Events)/dDb is a constant Bubble Frequency - sec-1 12 (U-Umf)/Umf 0.2 1.2 1.5 2.0 Probability on an event require tracer encounter a bubble with tracer is (x-area of bubble/x-area of bed) 8 4 0 1 2 3 4 5 Db - cm Number of bubbles in bed= d(Events)/dDb / (Dbub /Dbed )2 Bubble Frequency ~1/(Dbub)2 20 177-250 glass beads 177-250 glass beads Bubble frequency - sec-1 15 (U-Umf)/Umf 0.3 0.6 1.1 10 5 0 1 2 3 4 5 Db - cm

Conclusions Preliminary evaluation appears promising for determining bubble size statistics from MPT measurements An indirect measurement (like exoplanet detection from star brightness variability) Vector nature of magnetic field has potential to measure more bed properties like shear and turbulence What s next? Make measurements in single orifice bed with controlled known bubble size One instrument does both solids motions and bubble size distributions

Publications E. Patterson, J. Halow, and S. Daw, Innovative Method Using Magnetic Particle Tracking to Measure Solids Circulation in a Spouted Fluidized Bed, Ind. Eng. Chem. Res. 2010, 49, 5037 5043. J. Halow, K Holsopple, B. Crawshaw, S. Daw, C. Finney, Observed Mixing Behavior of Single Particles in a Bubbling Fluidized Bed of Higher-Density Particles, Ind. Eng. Chem. Res.,2012, 51, 14566-14576. C.S. Daw, J. Halow, A Random Walk Model for Biomass Particle Mixing in Bubbling Fluidized Beds, Ind. Eng. Chem. Res., 2014 J. Halow, An Update on Magnetic Particle Tracking, NETL Multiphase workshop, August, 2015, Morgantown, WV

Background Understanding solids motion in multiphase systems is neede for many processes Various methods have been used -- 2-D beds, tracer methods (radioactive, fluorescent, color, temperature, etc) and tomographic methods, in bed probes Passive magnetic tracking is non-invasive, safe, inexpensive and easy to use All methods have drawbacks and limitations

MTPS Current Capabilities Beds up to 10 cm in diameter have been studied (larger sizes possible) Sampling rates up to 200 hertz Runs times to 10 minutes Sensitivity <0.1 milligauss with smallest tracers equivalent to ~30 cm Temperatures to 200-300 Centigrade possible Can be applied to spouting, bubbling, circulating fluid beds, granular flow or liquid flow systems Tracer sizes > ~ 2 mm and densities > 0.4 g/cc Trade offs can be made with tracer size, bed size, bed properties to extend range of experiements

Why linear correlations? Actual bubble size number distributions are not linear Event occurs when a bubble encounters a tracer so Probability on an encounter of any bubble with tracer is (x-area of bubble/x-area of bed) Or (Dbub /Dbed )2 Number of bubbles = Events x (Dbub /Dbed )2 Number distribution is 1/ (Dbub)3