Tungsten Structures for High Heat Flux Components: Opportunities & Challenges

Tungsten has a long history in fusion research, with applications in high-heat-flux components. He-cooled W structures offer performance advantages, such as high heat flux capability and good safety characteristics. Various design configurations and cooling schemes have been developed, with a focus on complexity vs. performance trade-offs.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

page 1 of 15 Tungsten Structures for High Heat Flux Components: Opportunities & Challenges M. S. Tillack and the ARIES Team Japan-US Workshop on Fusion Power Plants and Related Advanced Technologies 22-24 February 2011

page 2 of 15 Tungsten has a long history in fusion research 1. Often chosen for its PMI properties As a limiter in PLT (1970 s) As a coating e.g.in ASDEX since 1990 s As armor in the ITER divertor 2. In ARIES-ST we proposed W as a heat sink material, requiring mechanical and pressure-vessel functions See: ARIES-ST Plasma-Facing Component Design and Analysis, Fusion Eng. & Design49 50 (2000) 363-369. 3. Since then, design efforts have expanded in the US and EU See: Recent US Activities on Advanced He-Cooled W-Alloy Divertor Concepts for Fusion Power Plants, Fusion Engineering & Design, 86 (2011) 71-98.

page 3 of 15 He-cooled W structure offers significant performance advantages for PFC s High conductivity and strength enable high heat flux capability >10 MW/m2 is possible (maybe >15 MW/m2) o High temperature capability gives high conversion efficiency. o Good activation, radiation damage and safety characteristics. o Currently the subject of much attention in the design and materials R&D communities. o R&D in EU on their jet-cooled finger design (HEMJ) Significant increase in materials research in the US

page 4 of 15 The ARIES-ST power core used W structures in the divertor and actively-cooled stabilizers Dual-cooled (He + PbLi) blanket He-cooled high-heat-flux components

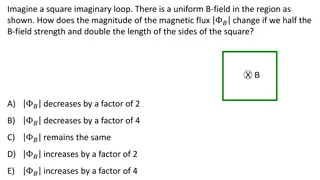

page 5 of 15 Three configurations and cooling schemes were scoped in ARIES-ST 1. 2. 3. Slot duct with extended surfaces (fins) Porous metal heat exchanger in tube Normal (impinging) flow 12 MPa 5 MW/m2 Ti-25Cr-3Be braze

page 6 of 15 Far more detailed W-He divertor designs have been developed since ARIES-ST T-tube Plates with jet and/or pin-fin cooling Finger/plate combinations Fingers

page 7 of 15 These concepts trade complexity vs. performance T-Tube: ~1.5 cm diameter x 10 cm long Impinging slot-jet cooling ~110,000 units for a full power plant EU finger: 2.6 cm diameter Impinging multi-jet cooling ~535,000 units for a full power plant Plate: 20 cm x 100 cm Impinging slot-jet cooling (with pin fins) ~750 units for a full power plant Combined plate and finger Increased design margin in exchange for more finger units, ~89,000 30 Pumping power/Thermal power (%) 25 "Plate" Finger 20 T-tube 15 10 5 0 4 6 8 10 12 14 16 Surface Heat Flux (MW/m2)

page 8 of 15 Material options and properties used in design Pure W W-alloy VM-W W-1%La2O3 or W-1.1TiC ppm of Al2(SiO3)3 or K2SiO3 Composition 100% W Drawn and rolled from sheet Fabrication HIP HIP Armor Thin HHF shell (up to 1 mm) Application Structures (or back plates) Minimum T 800 C 800 C 800 C Maximum T 2500 C (2/3 mp) 1200 C >1300 C Uniform elongation 1.6% at 270 C, 2% at 1200C Unknown (same as W) Unknown (same as W) Yield strength at 1200 C 346 MPa 246 MPa (same as W) Thermal cond. at 1200 C 108 W/mK 96 W/mK Same as W Fracture toughness <30 MPa-m1/2 <30 MPa-m1/2 <30 MPa-m1/2 Note: W-Re alloy is considered undesirable due to transmutation and waste disposal concerns

page 9 of 15 Material applications in the finger divertor Plasma facing armor - Pure W Tiles operate in a temperature range of ~1000 C to 2000 C, without strict requirements on mechanical strength. Good conductivity is required. The most economical way to fabricate tiles is by tungsten powder HIP or injection molding. Cup-shaped thimbles - VMW Vacuum metalized W is doped with ppm levels of K, offering improved mechanical properties and a higher re-crystallization temperature. The thinner the better. Since the thimble wall is ~1 mm thick, we can take advantage of VMW and fabricate them by deep drawing of a thin sheet, rolled in two directions. Front, side and back plates - WL10 (W-1%La2O3) The plates are constructed by brazing together the front, back and side plates. All these plates have thickness < 10 mm and operate in a small temperature range between 750 C 850 C. The material requirements are relatively moderate, and it should be possible to fabricate them from standard tungsten plates as an alternative. W (pure) VM-W (Finger unit) WL10 (W-1%La2O3) (Front/Side/Back Plates)

page 10 of 15 Issues related to tungsten as a structural and heat sink material for fusion 1. Inherently low ductility and fracture toughness 2. Limited temperature window (800~1200) due to DBTT and recrystallization, and overlap with steels 3. Difficult fabrication limited to simpler shapes and joining with brazes 4. Uncertain plasma-material interactions 5. Tritium retention

page 12 of 15 Limited ductility can lead to catastrophic failure Faleschini JNM 2007 (M. Rieth, SOFT 2010)

page 13 of 15 Consequences of surface evolution are still under investigation W cracking after a few shots at 0.5 MJ/m2 Very complex behavior of surfaces vs. temperature, ion energy, etc. (R. Doerner) Fuzzy W does not crack after repeated exposure at 0.7 MJ/m2

page 14 of 15 High tritium retention can occur in tungsten as a result of trapping sites (D. Whyte)

page 15 of 15 Summary 1. Tungsten as a structural material offers the possibility of high performance in a divertor operating at high temperature and high heat flux. 2. Design efforts have shown the possibility of reliable operation above 15 MW/m2 heat flux. 3. As a relatively new structural material in fusion R&D programs, many problems remain to be solved.