Siddhi Pharma Equipment - Roto Cone Vacuum Dryer (RCVD) & Double Cone Vacuum Dryer

Siddhi Pharma Equipment specializes in manufacturing and exporting plants and machinery for pharmaceuticals, cosmetics, chemicals, food, and beverage industries. They offer innovative Roto Cone Vacuum Dryers (RCVD) and Double Cone Vacuum Dryers with superior drying efficiency and precise models for various industries. The dryers feature advanced technology, robust construction, and are easy to clean and maintain, delivering uniform and high-quality dried products. Contact Siddhi Pharma Equipment for all your technical requirements in pharmaceutical, food, chemical, cosmetics, and allied industries.

Uploaded on Oct 10, 2024 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

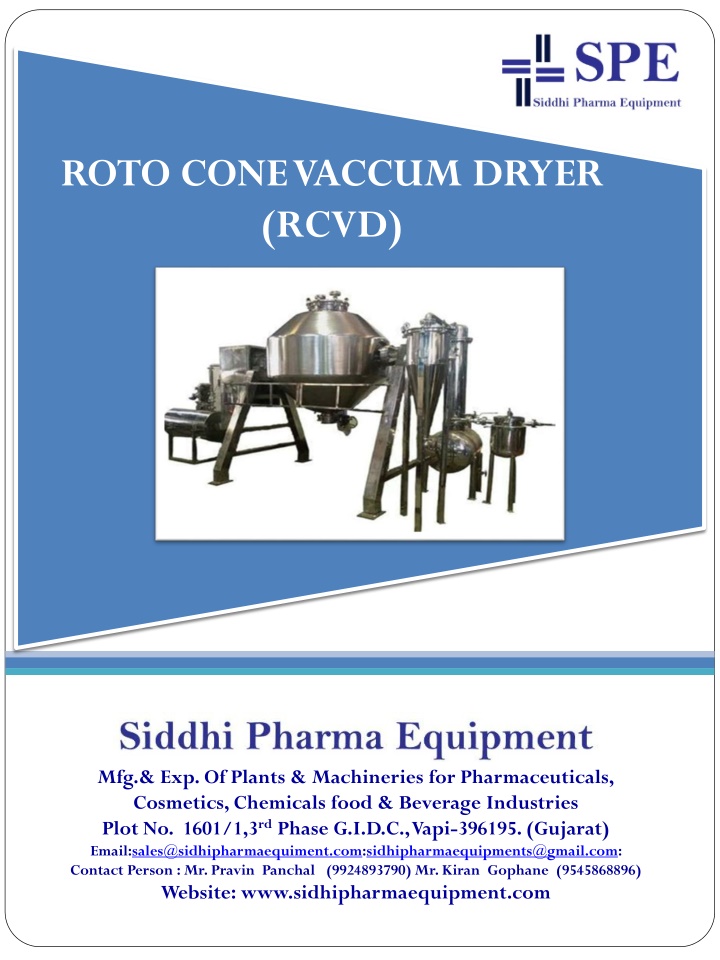

ROTO CONE VACCUM DRYER (RCVD) Mfg.& Exp. Of Plants & Machineries for Pharmaceuticals, Cosmetics, Chemicals food & Beverage Industries Plot No. 1601/1,3rd Phase G.I.D.C., Vapi-396195. (Gujarat) Email:sales@sidhipharmaequiment.com:sidhipharmaequipments@gmail.com: Contact Person : Mr. Pravin Panchal (9924893790) Mr. Kiran Gophane (9545868896) Website: www.sidhipharmaequipment.com

DOUBLE CONE VACUUM DRYER : The DOUBLE CONE VACUUM DRYER also utilizes the vacuum drying technology with greater drying efficiency. Wet product goes through an indirect heating process and agitation with tumbling action, all while inside a vacuum to achieve rapid drying. In this process, recovery of solvent is also possible through condensation processes. With constant innovation, the RVCD manufacturer has been able to deliver highly precise models that achieve thorough drying of product, uniformity of products, reduced drying time and an easy to clean and maintain machine. The roto cone vacuum dryer is mainly used in chemicals processing and pharmaceutical industries where air contamination can easily occur with other types of dryers.

Silent Features : Dry Mechanical Seal for vacuum side. Dry Mechanical Seal for Waterside. FLP Motor & FLP Control panel enclosed in SS304 panel. Digital Temperature Indicators (FLP) at Hot Water inlet and outlet. Digital Temperature Indicator (FLP) and Dial Vacuum Gauge in vapor line. Digital Temperature Controller (FLP) with Pneumatic Valve at Hot water inlet. Provision for Nitrogen purging Vacuum release with interlocking to isolation valve. Temperature and Vacuum Gauges (Dial Type) on Cone. Safety Guard/railing telescopic type with limit switch (FLP) with interlocking. Drain plug and safety valve on HW/Steam Jacket. Pulse jet type dust filter is provided in side the cone. Positioning wheel /inching button for cone. Advantageous\ Benefits : Reduces drying time Eliminates need for re-drying of lumps Handling and exposure of final product is avoided Gives uniform size dry product. System can process crystalline or amorphous powders which are prone to lumps Easy to clean internal surface ensures purity of product . Optimum and continuous vacuum maintenance during process Uniform material shuffling over the heated contact surface of the cone.

Technical Specification : Single Source Provider for all your technical requirements. One of the most important Siddhi Pharma Equipment guideline is to be closest to our Customers. We strive to create end-to-end solutions that meet our clients needs and their expectation. Application : Pharmaceutical Food Chemical Cosmetics Allied Industry