Siddhi Pharma Equipment - Spray Dryer for Pharmaceutical, Cosmetics, and Food Industries

Siddhi Pharma Equipment specializes in manufacturing and exporting spray dryer plants and machineries for pharmaceuticals, cosmetics, chemicals, food, and beverage industries. Their spray dryer unit uses centrifugal atomization to convert liquid solutions into powder products rapidly, making it ideal for heat-sensitive materials. The equipment offers fast drying speeds, good uniformity, and easy control over particle size and moisture content. With a focus on customer satisfaction, Siddhi Pharma Equipment provides end-to-end solutions tailored to meet the needs of various industries.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

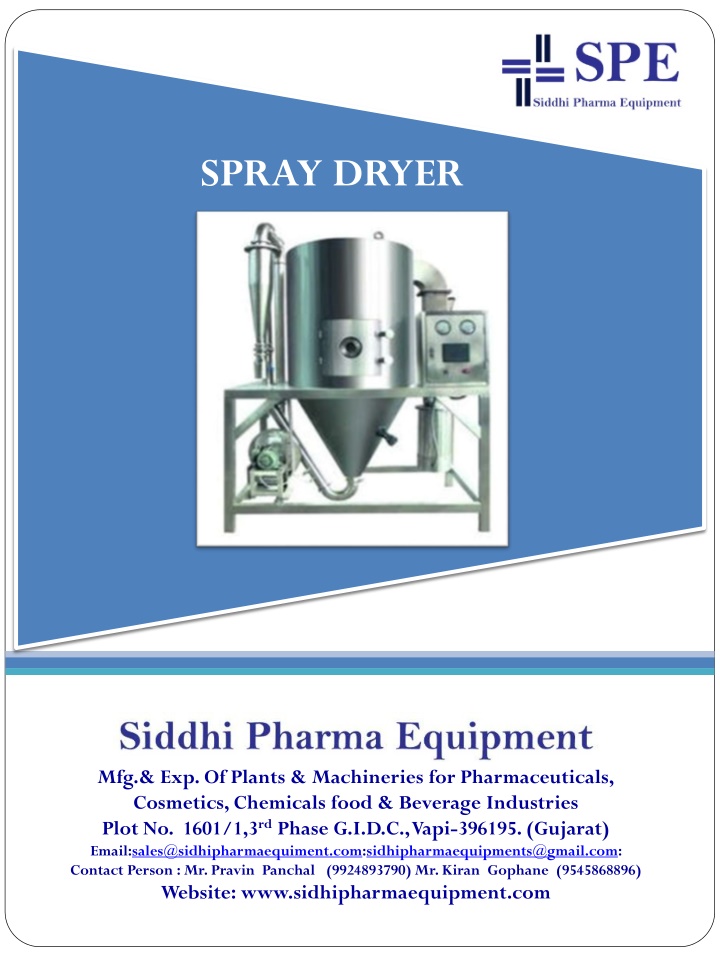

SPRAY DRYER Mfg.& Exp. Of Plants & Machineries for Pharmaceuticals, Cosmetics, Chemicals food & Beverage Industries Plot No. 1601/1,3rd Phase G.I.D.C., Vapi-396195. (Gujarat) Email:sales@sidhipharmaequiment.com:sidhipharmaequipments@gmail.com: Contact Person : Mr. Pravin Panchal (9924893790) Mr. Kiran Gophane (9545868896) Website: www.sidhipharmaequipment.com

SPRAY DRYER : SPRAY DRYER unit is a kind of centrifugal atomizer, which has centrifugal and pressure type. It can atomized solution, suspension liquid, emulsion and slurry into small drops of liquid (surface area increased), through the hot air to dry rapidly (within a few seconds to tens of seconds), thus directly get powder products. Raw material is throws out and atomized by centrifugal force role in rotary table (90-160 - m/s peripheral speed) from the plate edge, the whole system adopts hot air circulation drying

Silent Features : The drying speed is fast, and after the spraying of the liquid materials, the superficial area of the materials is increased greatly. In the hot air flow, 95-98% of water can be evaporated at a moment. The time to complete the drying just needs several seconds, that is especially suitable for the heat sensitive materials. This product has good uniformity, liquidity and solubleness, the product purity and quality is good, too. The production process is simple the operation is convenient. For the liquid with 40-60% of moisture content, they can be dried into powder and granular products at one time. It won t need to be crushed or screened after the drying, which reduces the production procedures and increases the product purity. For the product grain size, bulk density and moisture content, it can be adjusted by changing the operating conditions at the certain ranges, so it is convenient to control and manage. Advantageous\ Benefits : The dry particle size can be easily controlled by atomization of the liquid feed and the design of the hot gas inlet. . The shape of most spray dried particles is spherical, which provides for fluid- like flow properties. This makes many downstream operations, such as packaging, pressing, filtering, and handling easier and less costly. The surface area produced by atomization of the liquid feed enables a short gas residence time, ranging from 3-40 seconds depending upon the application, which permits spray drying without thermal degradation.

Technical Specification : AS PER CLIENT SPECIFICATION Single Source Provider for all your technical requirements. One of the most important Siddhi Pharma Equipment guideline is to be closest to our Customers. We strive to create end-to-end solutions that meet our clients needs and their expectation. Application : Pharmaceutical Food Chemical Cosmetics Allied Industry