Sand-Lime Bricks: Advantages, Disadvantages & Applications

Sand-lime bricks, made from sand and lime, offer numerous advantages in masonry construction, including uniformity, strength, fire resistance, and reduced construction costs. However, they also have limitations such as poor abrasion resistance. Discover the uses, characteristics, and differences of sand-lime bricks in this comprehensive guide.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

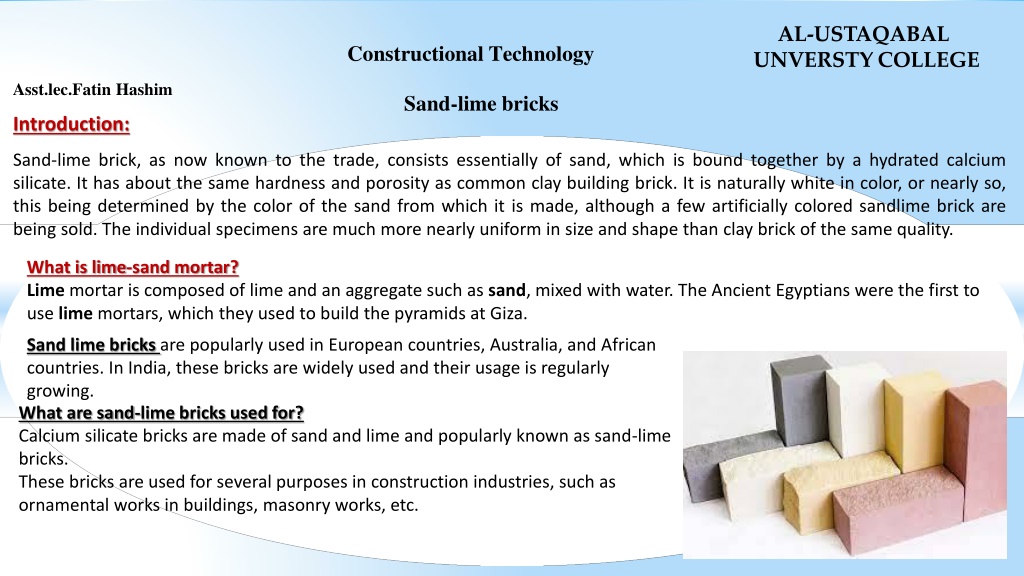

AL-USTAQABAL UNVERSTY COLLEGE Constructional Technology Asst.lec.Fatin Hashim Sand-lime bricks Introduction: Sand-lime brick, as now known to the trade, consists essentially of sand, which is bound together by a hydrated calcium silicate. It has about the same hardness and porosity as common clay building brick. It is naturally white in color, or nearly so, this being determined by the color of the sand from which it is made, although a few artificially colored sandlime brick are being sold. The individual specimens are much more nearly uniform in size and shape than clay brick of the same quality. What is lime-sand mortar? Lime mortar is composed of lime and an aggregate such as sand, mixed with water. The Ancient Egyptians were the first to use lime mortars, which they used to build the pyramids at Giza. Sand lime bricks are popularly used in European countries, Australia, and African countries. In India, these bricks are widely used and their usage is regularly growing. What are sand-lime bricks used for? Calcium silicate bricks are made of sand and lime and popularly known as sand-lime bricks. These bricks are used for several purposes in construction industries, such as ornamental works in buildings, masonry works, etc.

Advantages of Calcium Silicate Bricks: There are many advantages of calcium silicate bricks when used in masonry construction, and they are: *Mortar required for providing plaster on calcium silicate bricks is very less. *The color and texture of these bricks are uniforms. *The compressive strength of sand-lime bricks is about 10N/mm2. So, they are well suitable for multi-storied buildings. *For constructions in clay soils, these bricks are more preferable. *The trouble of Efflorescence does not arise in the case of sand-lime bricks. *Not only bricks, blocks, and tiles can also be made using calcium silicate. *Sand lime bricks provide more comfort and accessibility for architects to attain the desired shape and designs *These bricks have accurate shape and size with straight edges. *The solar heat effect is reduced on exposed walls made of calcium silicate bricks. *Colored sand-lime bricks do not need any finish to the wall, so, the cost reduces. *These bricks have great fire resistance and water repellant properties. *Calcium silicate brick walls resist noise from outside. *The cost of construction gets reduced by about 40% of the total cost due to the following factors: 1. Wastage of calcium silicate products is very less. 2. Less quantity of mortar is needed. 3. Thickness of the wall can be reduced when constructed using these bricks because of high compressive strength.

Disadvantages of Calcium Silicate Bricks: In some conditions, calcium silicate bricks are not suitable and their disadvantages are: *If the clay is available in plenty, clay bricks are more economical than calcium silicate bricks. *These are not suitable for laying foundations, because they cannot provide resistance to water for a longer period. *They cannot also resist fire for longer periods so, they are not suitable for building furnaces, etc. *The abrasion resistance of these bricks is very less so, they cannot be used as paving materials. How can you tell if a brick is calcium silicate? In their natural state, calcium silicate bricks are white to a creamy off-white color, but the addition of ochre (buff or cream colors), iron oxides (pink, red, brown or black) or chrome oxide (green) can enable a very wide variety of colors to be produced.

What is the difference between hydraulic lime and hydrated lime? Hydraulic limes (so-called because they set underwater, not dissolve in water) are made in the same way as non-hydraulic lime but using different limestone. They are sold as hydrated lime and have an initial set when water is added, followed by hardening while they absorb carbon dioxide What is the best sand for lime mortar? For lime putty mortars, the sand used for building, painting, and backing coats of render and plaster should be a washed sharpcoarse sand. We use sharp sand to BS882 which is free of vegetable matter, clay, and salts. For finishing coats of internal plaster, we mix a very fine, kiln-dried sand with the lime putty. Materials Used for Sand Lime Bricks The materials listed below are used for the production of calcium silicate bricks. Sand ,Lime ,Water,Pigment Sand Calcium silicate bricks (Ca O Si) contain a high amount of sand is about 88 92%. It means the properties of these bricks depends upon the characteristics of sand used. So, the sand used shall be well-graded and should not contain any impurities like organic matter, soluble salts, etc., not exceed 4% only which helps the brick in pressing and provides smoother texture. Different colored sands affect the final color of the natural brick, with red sand, creating a brick that tends to be red with a slight finish, and white sand producing a near white brick.

Lime The lime content in calcium silicate bricks ranges from 8 to 12%. The lime used shall be of good quality, and of high calcium. The lime used must be free of any impurities and must be completely moistened (calcium hydroxide) before the bricks go through the hardening process. Fly ash or rice husk is sometimes used to improve the properties of lime paste. Water Clean water should be used for preparing calcium silicate bricks. Seawater or water containing soluble salts or organic matter more than 0.25% is not suitable. Pigment Pigments are generally used to give color to the bricks. They are added to the sand and lime while mixing.Total weight of brick contains 0.2 to 3 % of pigment quantity. Different pigments used to get different colors are tabulated below:

Manufacturing of Calcium Silicate Bricks: In the first step, suitable proportions of sand, lime and pigment are taken and mixed thoroughly with 3 to 5 % of water. Then paste with moldable density obtains.The mixture is molded into bricks using rotary table press which uses mechanical pressure to press the bricks. The pressure of pressing varies from 31.5 to 63 N/mm2..As each brick is produced it is normally automatically stacked to a wait transfer to the hardening chamber known as autoclave In the final stage, bricks are placed in an autoclave. An autoclave is a steel cylinder with tightly sealed ends. The diameter ofthe autoclave is bout 2m and the length is about 20m. Essentially the autoclave is a large pressure cooker into which the uncured bricks are conveyed on trucks running on rails. After placing bricks in this closed chamber saturated steam pressure is released which is about 0.85 to 1.6 N/mm2. The temperature inside the chamber is raised up to approximately 200 C and the reaction process begins. Silica content in sand and calcium content in lime reacts and forms a crystal-like compound called calcium hypo silicate. This process is done for 6 to 12 hours. Then the steam is shut off through a valve in an autoclave, this allows the bricks to cool steadily. Finally, the obtained bricks are transported to the workplace Are the lime sand bricks made of sand only, or what? Lime sand bricks (also known as calcium silicate bricks) are made by mixing sand and (fly ash as an additive) and lime. Pigments can also be added to the color. Then the mixture is formed under pressure to form bricks; The materials are linked together by a chemical reaction that occurs when wet bricks dry under heat and pressure when placed in an autoclave. Can you add lime to cement? Incorporating an appropriate proportion of hydrated lime into a cement-based mixture improves plasticity and workability, making the product easier to handle on the trowel. Hydrated lime also increases water retention, which helps to improve the contact and bond with the other material.

What is hydrated lime made of? Hydrated lime made from pure calcium oxide will be roughly 74 percent calcium oxide and 24 percent chemically combined water. Dolomitic hydrated lime will have about 48 percent calcium oxide, 34 percent magnesium oxide and 17 percent water. Hydrated lime is white and powdery. How do you stop lime mortar from cracking? In general, when the mortar has stiffened up, it should be firmly compacted into the joints by beating with a stiff bristle brush. This will help eliminate any initial shrinkage cracking and ensure that the mortar is fully compacted into the joint with a good bond to the surrounding masonry. What is the difference between lime mortar and lime plaster? The principal difference between a lime mortar and a lime plaster or render is one of consistency. ... Whilst lime mortar is predominantly a building material, used to bind together masonry, lime plasters and renders need to be spreadable and may therefore contain more water and a finer aggregate

In the final stage, bricks are placed in autoclave https://youtu.be/VaZBqToeOu8 Sand lime brick production