Recent Developments in Vertical Electropolishing at KEK-Marui

Recent results and advancements in Vertical Electropolishing (VEP) at KEK-Marui have shown promising outcomes for cost reduction and cavity treatment techniques, including the use of wing-cathode and ninja-cathode developments. The progress towards vertical tests at KEK demonstrates ongoing innovation and challenges in the field.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

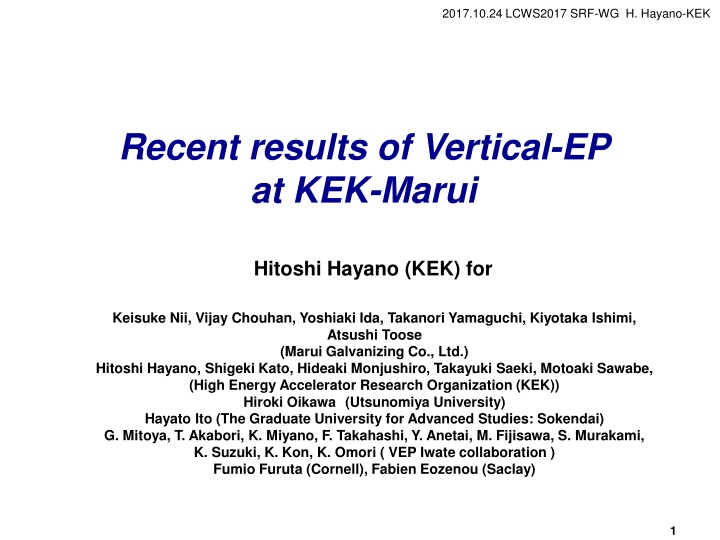

2017.10.24 LCWS2017 SRF-WG H. Hayano-KEK Recent results of Vertical-EP at KEK-Marui Hitoshi Hayano (KEK) for Keisuke Nii, Vijay Chouhan, Yoshiaki Ida, Takanori Yamaguchi, Kiyotaka Ishimi, Atsushi Toose (Marui Galvanizing Co., Ltd.) Hitoshi Hayano, Shigeki Kato, Hideaki Monjushiro, Takayuki Saeki, Motoaki Sawabe, (High Energy Accelerator Research Organization (KEK)) Hiroki Oikawa (Utsunomiya University) Hayato Ito (The Graduate University for Advanced Studies: Sokendai) G. Mitoya, T. Akabori, K. Miyano, F. Takahashi, Y. Anetai, M. Fijisawa, S. Murakami, K. Suzuki, K. Kon, K. Omori ( VEP Iwate collaboration ) Fumio Furuta (Cornell), Fabien Eozenou (Saclay) 1

US-Japan Cost-down : A-4. Cavity chemical treatment The change of the SC-cavity chemical treatment, from horizontal EP and sulfuric acid + HF (TDR) to vertical EP (VEP) + non-HF solution + bipolar EP, will be effective to ILC cost down. VEP with wing-cathode Bipolar EP using non-HF solution ILC EP cost-down The development of vertical EP (VEP) is the first step. 2

Wing Cathode (Ninja-cathode) Development partial metal wing during insertion during EP Al small electrode Al small electrode partial metal wing metal wing insulator wing Flat removal was attained 4

Roughness Monitoring by coupon cavity partial metal wing Viewport insulator wing metal wing smooth surface finish was attained partial metal wing metal wing Viewports enable us to look H2bubbles generation and flow insulator wing 5

Single-cell VEP at Marui motor for cathode rotation water spray for cavity outside cooling partial metal wing insulator wing 13-15V, 30mA/cm2, 28degree, 50rpm, 5L/min 6

Recent 1-cell VEP at Marui towards vertical test at KEK 07 September, 2017 * Vertical test was suspended by the accident, AC-power-down during cool-down, Vac. pressure was increased, then severe Q-desease happened on 21 Sep. 2017. The next vertical test is scheduled in November. 7

Recent Single-cell VEP at Marui Side View EP EP Top View Ninja-5 single-cell cavity with support-jig Automated EP acid control valves ( VEP Iwate collaboration) VEP mount 8

Recent Single-cell VEP at Marui Cavity-bottom acid reservoir Cavity-top acid reservoir cost effective ALL PVC-made system ( VEP Iwate collaboration ) EP acid reservoir tank has 5-filtered-room for H2bubble erasing: it was effective. EP acid reservoir tank with water-chiller 9

Recent Single-cell VEP at Marui before VEP after VEP shiny finish surface was attained!! 10

Recent Single-cell VEP at Marui 60 1 8 Removal thickness ( m) 50 UP mark 1,9 40 2,10 3,11 30 4,12 5,13 6,14 Side view 20 10 7,15 0 8,16 1 2 3 4 5 6 7 8 Point of measurement Upper Lower 60 9 16 9 16 Removal thickness ( m) 50 40 Top view 30 20 1 8 10 0 Average removal 39 m 8 16 3 11 4 12 5 13 6 14 2 10 7 15 9 1 Point of measurement Upper Lower Flat removal was attained!! Lower Upper 11

Recent Wing Cathode (Ninja-cathode) for 9-cell Insulating wings (3 wings per cell) Ninja-5 I-V curves of the coupons Side View Top Cell Top Iris Equator Bottom Iris Cathode housing covered with meshed sheet (catch-up H2bubbles) EP EP Top View Center Cell Enhanced cathode surface area (additional Al electrodes) Top Iris Equator Bottom Iris Parameters Condition Acid (H2SO4:HF) 9:1 VEP condition (Follow the 1-cell VEP best condition) Bottom to top 50 rpm Acid flow direction Acid flow rate 5-7 L/min Bottom Cell Top Iris Equator Bottom Iris Cathode rotation speed Cathode Ninja-5 Voltage ~13 V Current Density 18 mA/cm2 Cavity temperature 15 C 13V 13

Roughness Monitoring by 9-cell coupon cavity The world s first 9-cell coupon cavity has been fabricated. 9-cell coupon cavity Coupon holders and view ports (Near iris position) Coupon holder (Equator position) In order to optimize VEP parameters, a 9-cell coupon cavity was fabricated. Nb coupons are set on equator positions of 1st, 5th and 9th cell. View ports with Nb coupon are set near iris of 1st, 5th and 9th cell. EP current can be measured for individual coupon. Coupons are removed for surface analysis. 14

Roughness Monitoring by 9-cell coupon cavity Roughness (Rz) Microscope images of the coupons Almost smooth surface were attained, except one location. 15

EP removal thickness of 9-cell coupon cavity Removal Thickness Average removal: 35 m Asymmetry between top and bottom (60 m - 30 m) 0 Still Non-Flat removal for 9-cell cavity Top View Cavity was connected to Automated EP acid control valves 180 16

Recent 9-cell VEP at Marui towards vertical test at KEK 05 October, 2017 * Vertical test was suspended by the accident, Vaccum leak happened at RF pickup feedthrough silver-brazing during 120C baking, on 15 Oct. 2017. 17

Recent 9-cell VEP at Marui VEP Conditions cavity was water-spray cooled Cathode: Ninja cathode v5 (contains 3 wings in each cell) Cathode rotation: 20 rpm Acid flow rate: ~5 L/min Voltage: ~14-16 V Cooling: Acid cooling in acid reservoir using Chiller-1 (5 kW) Spray of water cooled by chiller-2 (1.2 kW) Cavity-top acid reservoir was filled with bubbles Target cavity temperature ~ 15 Target current: 160 A Target removal thickness: 50 m C EP acid reservoir tank has 5-filtered-room for H2bubble erasing, but still bubbles were remained in this 9-cell VEP. 18

Surface finish From the Top (Before VEP) From the Top (After VEP) Input coupler Flange Bubbles might gathered at the flange of input coupler and made the surface rougher. HOM cup was also rough surface. 19

Vertical Tests of VEP 1-Cell Cavities at Cornell and Saclay 20

Collaborative Study with Cornell and Saclay Collaborator : Fumio Furuta (Cornell), Fabien Eozenou (Saclay) ( Cornell ) ( Saclay ) 21

Cathode comparison with Cornell VEP Cornell-KEK Feb. 2016 VEP at Cornell using Marui-Ninja-cathode During EP insertion Ninja-3 Concept of newly developed Ninja-cathode (retractable wing for H2bubbles flow control and acid flow control) KEK-Marui-Cornell development 1-cell Cavity VEP With Ninja-cathode at Cornell Right Vertical Test shows, KEK-VEP (Ninja cathode) has similar performance with Cornell-VEP (rod cathode), reached to 35MV/m. 22

Summary of recent VEP development VEP setup and unique Ninja cathodes were developed for surface treatment of Nb cavities. VEP parameters and design of the Ninja cathode were optimized for single cell cavity. Smooth surface and symmetric removal of Nb along cavity length were obtained with the Ninja cathode. The Ninja cathodes and optimized VEP parameters were applied to two single-cell cavities which showed good performance in vertical tests performed at Cornell University and CEA-Saclay. The world s first 9-cell coupon cavity has been fabricated. VEP parameters are being optimized using the cavity. Vertical test of 9-cell cavity with VEP & Ninja-cathode was suspended by the feedthrough leak. The reason of leak is now under investigation. 23

End of slide 24