Pumping System Residual Pressure Head Calculation

Calculating the residual pressure head in a pumping system with various pipe fittings involves determining head losses at different points and transitions in the system. The solution includes calculations for head loss between points, friction factors, contraction and expansion transitions, and more. Utilizing equations and diagrams, the process is explained step by step for accurate determination of the residual pressure head at the pipe outlet.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

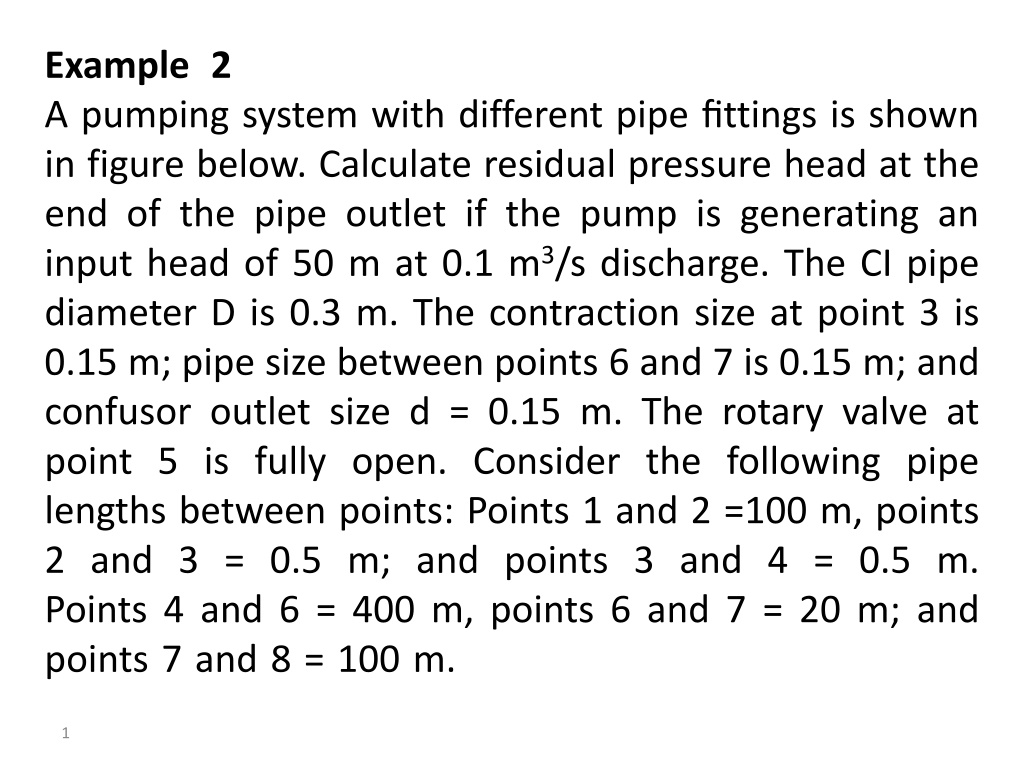

Example 2 .. A pumping system with different pipe fittings is shown in figure below. Calculate residual pressure head at the end of the pipe outlet if the pump is generating an input head of 50 m at 0.1 m3/s discharge. The CI pipe diameter D is 0.3 m. The contraction size at point 3 is 0.15 m; pipe size between points 6 and 7 is 0.15 m; and confusor outlet size d = 0.15 m. The rotary valve at point 5 is fully open. Consider the following pipe lengths between points: Points 1 and 2 =100 m, points 2 and 3 = 0.5 m; and points 3 and 4 = 0.5 m. Points 4 and 6 = 400 m, points 6 and 7 = 20 m; and points 7 and 8 = 100 m. . 1

Solution: 1. Head loss between points 1 and 2. Pipe length 100 m, flow 0.1 m3/s, and pipe diameter 0.3 m. calculate for temperature of 20 C: 2

1.1651 ? 25 = 1.792 10 61 + 1.165 1 20 25 = 1.792 10 61 + =1.012 *10-6 m2/s ??=? ? 4 ? ??? = 4 0.1 ??= ? 1.012 10 6 0.3 ??= 419380 3

Using Table 1 for CI pipes, is 0.25 mm. The friction factor f is calculated by using the following Eq. : 3.7 ?+5.74 ??0.9 0.25 10 3 3.7 0.3 ? = 0.0197 Using the following equation to calculate the head loss hf12 in pipe (1 2) : hf12=8 f L Q2 ?2 9.81 0.35 ????= ?.???? 2 ? = 1.325 ?? 2 5.74 ? = 1.325 ?? + 4193800.9 8 0.0197 100 0.12 2g D5= 4

2. Head loss between points 2 and 3 (a contraction transition). For D = 0.3, d = 0.15, and transition length = 0.5 m, the contraction angle ??can be calculated using the following Eq. : ?1 ?2 2? ??= 2 tan-1 0.3 0.15 2 0.5 ??= 2 tan-1 5 ??= 0.298 ???????.

1/3 ??= 0.315 ?? ??= 0.315 0.298 1 3 ??= 0.210 Using the following Eq. to calculate the head loss hm23 8 ?2 ?2? ?1 8 0.32 0.152 2 0.12 ?2 9.81 0.154 0.34 ????= ?.??? ? 2 ?1 2 2 ?2 4 ?2 ?= ?? 4 ?23= 0.21 6

3. Head loss between points 3 and 4 (an expansion transition). For d = 0.15, D = 0.3, the expansion ratio r =D/d= 2, and transition length = 0.5 m. calculate the expansion angle ?? ??= 2 tan-1 2? ??= 2 tan-1 2 0.5 ??= 0.298 ???????. ??= ?? ?1.67 ?? ?2 ?1 0.3 0.15 0.533 ? 2.6 0.5 0.25 0.6 ? ?? 1 + 3 0.533 2 2.6 0.5 0.25 0.29831 + 0.6 21.67 ? 0.298 0.298 ??= ??= 0.716 7

2 ?1 ?2? ?1 2 2 ?2 4 ?2 8 ?2 ?= ?? 4 8 0.32 0.152 2 0.12 ?2 9.81 0.34 0.154 ?23= 0.21 ????= ?.??? ? 8

4. Headloss between points 4 and 6. =1.012 *10-6 m2/s, ??= 419380 , = 0.25 mm , D=0.3m, Q=0.1 m3/s, pipe length= 400m. 2 3.7 ?+5.74 ? = 1.325 ?? ??0.9 2 0.25 10 3 3.7 0.3 5.74 ? = 1.325 ?? + 4193800.9 ? = 0.0197 9

Using the following equation to calculate the head loss hf46 in pipe (4 6) : hf46=8 f L Q2 8 0.0197 400 0.12 ?2 9.81 0.35 2g D5= ????= ?.???? 5. Head loss at point 5 due to rotary valve (fully open). For fully open valve ? = 0 2.3 ? ??= 133 ? 2? ??= 0 hm5 =0 m 10

6. Head loss at point 6 due to abrupt contraction. For D = 0.3 m and d = 0.15 m, the form-loss coefficient will be: ?2 ?1 2.35 ??= 0.5 1 2.35 0.15 0.3 ??= 0.5 1 ??= 0.402 11

2 ?1 ?2? ?1 2 2 ?2 4 ?2 8 ?2 ?= ?? 4 8 0.32 0.152 2 0.12 ?2 9.81 0.34 0.154 ?6= 0.402 ???= ?.??? ? 12

7. Head loss in pipe between points 6 and 7. Pipe length = 20 m, pipe diameter = 0.15 m, and roughness height = 0.25 mm. ??=? ? 4 ? ??? = 4 0.1 ??= ? 1.012 10 6 0.15 ??= 838927 13

The friction factor f is calculated by using the following Eq. : 3.7 ?+5.74 ??0.9 0.25 10 3 3.7 0.15 ? = 0.0227 Using the following equation to calculate the head loss hf67 in pipe (6-7) : hf67=8 f L Q2 ?2 9.81 0.155 2 ? = 1.325 ?? 2 5.74 ? = 1.325 ?? + 8389270.9 8 0.0227 20 0.12 2g D5= ????= ?.??? ? 14

8. Head loss at point 7 (an abrupt expansion). An abrupt expansion from 0.15 m pipe size to 0.30 m. Kf = 1 2 ?1 ?2? ?1 2 2 ?2 4 ?2 8 ?2 ?= ?? 4 8 0.32 0.152 2 0.12 ?2 9.81 0.34 0.154 ?7= 1 ???= ?.??? ? 15

9. Head loss in pipe between points 7 and 8. Pipe length = 100 m, pipe diameter = 0.30 m, and roughness height =0.25 mm. ??=? ? 4 ? ??? = 4 0.1 ??= ? 1.012 10 6 0.3 ??= 419380 16

The friction factor f is calculated by using the following Eq. : 3.7 ?+5.74 0.25 10 3 3.7 0.3 ? = 0.0197 Using the following equation to calculate the head loss hf78 in pipe (7 8) : 2 ? = 1.325 ?? ??0.9 2 5.74 ? = 1.325 ?? + 4193800.9 hf78=8 f L Q2 8 0.0197 100 0.12 ?2 9.81 0.35 2g D5= ????= ?.???? 17

10. Head loss at outlet point 8 (confusor outlet). Calculate the form-loss coefficient: ? ? 3.5 0.3 0.15 3.5 ??= 4.5 ??= 4.5 ??= 5.5 V2 2g = Kf 8Q2 2g D4 hm = Kf 8 0.12 hm8 = 5.5 2 9.81 0.34 hm8 = 0.561 m 18

Total headloss : hL= 0.670 + 0.193 + 0.657 + 2.679 + 0 + 0.369 + 4.940 + 0.918 + 0.670 + 0.561 hL = 11.657 m Thus, the residual pressure at the end of the pipe outlet = 50 - 11.657 =38.343 m. 19