Physical Distribution in Marketing

Physical distribution in marketing involves the planning, implementation, and control of the physical flow of materials and goods from production to end-use to meet buyer needs. This process includes logistics management, components like order processing, transportation, warehousing, and inventory management, and objectives such as cost management and customer service. Balancing distribution cost and service trade-offs is crucial for achieving efficiency in physical distribution.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Chapter 9 Physical Distribution Chapter 2 PhysicalDistribution

Chapter Plan Concept & Definition Logistics Relation with other Marketing Mix Variables Importance of Physical Distribution Components of Physical Distribution Chapter 2 PhysicalDistribution

Definition Physical distribution involves planning, implementing and controlling the physical flows of materials and final goods from place of production to the place of end use to satisfy buyers needs. Philip Kotler Chapter 2 PhysicalDistribution

Logistics Logistics management includes both physical distribution and physical supply Chapter 2 PhysicalDistribution

Relation with Marketing Mix A. Product-physical Distribution FMCG- Mass Distribution Perishable product- shortest distri. B. Price-Physical Distribution Reciprocal Relationship C. Promotion-Physical Distribution Grab the market potential Chapter 2 PhysicalDistribution

Objectives of Physical Distribution Process 1. Total Cost Concept 2. Customer Service Concept a. Time b. Dependability c. Communication d. Convenience e. Accuracy Chapter 2 PhysicalDistribution

Objectives of Physical Distribution Process 3. Distribution Cost- service trade offs Achieve right balance between them Flexibility is important in balancing the cost and service Chapter 2 PhysicalDistribution

Component of Physical Distribution 1. Order Processing 2. Transportation 3. Warehousing 4. Material Handling 5. Inventory Management and Control Chapter 2 PhysicalDistribution

Order Processing a. Verifying customers credibility b. Checking for any outstanding payment c. Monitoring stock level d. Preparing invoice e. Arranging transporter f. Sending the consignment and information Chapter 2 PhysicalDistribution

Selection of the transportation mode 1. Suitability or nature of product 2. Affordability 3. Availability 4. Customers specifications 5. Competitor s transportation mode Chapter 2 PhysicalDistribution

Warehousing Type of warehouse 1. Private warehouse 2. Public warehouse 3. Distribution warehouse 4. Bonded warehouse 5. Mother depot Number and Size of Warehouses Chapter 2 PhysicalDistribution

Warehousing Location Availability of basic facilities such as electricity, water, labour, transport etc. Space Roads Government rules and regulations Chapter 2 PhysicalDistribution

Warehousing Layout 1. Proper lighting, ventilation, and fire precaution 2. Protection from temperature, moisture, etc 3. Security arrangement 4. Space arrangement Chapter 2 PhysicalDistribution

Warehousing Storage Methods Optimum use of space Ease in storing and picking Accurate identification of material Possible to follow FIFO Provision for fast moving items Chapter 2 PhysicalDistribution

Material Handling Involves placing and positioning of material to facilitate movement and storage Common equipments are conveyors, bucket Elevators, hoists, lifts, cranes, forklifts, trolleys, dumpers, trailors, trucks Chapter 2 PhysicalDistribution

Inventory Management & Control Major tool to cost reduction objective Just in time Reliability of suppliers Close communication between suppliers and customers Attention to quality Adequate storage facilities and transportation options Chapter 2 PhysicalDistribution

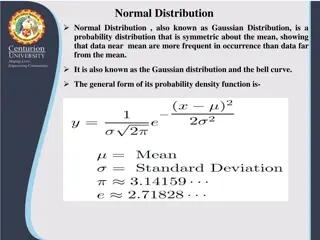

Economic Order Quantity (EOQ) At EOQ Ordering Cost=Carrying Cost EOQ =Square route ( 2AP/CU) Where, A= annual demand in units B= Ordering Cost per Order C= Carrying Cost U= Unit Price Chapter 2 PhysicalDistribution

Summary Physical Distribution is highly co-related with other variables of marketing mix Order processing, transportation, warehousing, material handing and inventory management and control are important components of physical distribution Chapter 2 PhysicalDistribution

Summary Material handling involves decision on placing and positioning of material to facilitate their movement and storage. Inventory control is a major tool for cost reduction, JIT and EOQ are useful techniques Chapter 2 PhysicalDistribution

Like us on Facebook: http://www.facebook.com/welearnindia Follow us on Twitter: http://twitter.com/WeLearnIndia Watch informative videos on Youtube: http://www.youtube.com/WelingkarDLP