Performance Degradation Summary for FRIB Cryomodule VT vs. Bunker

FRIB's performance degradation analysis focuses on validating the design of the cryomodule, with tests conducted under various operational conditions to assess parameters such as cryogenic losses, SRF subsystems performance, and cavity dynamics. The ReA6-1 cavity's performance, measured in terms of VT vs. bunker dynamic heat load, shows some degradation in QO, highlighting the complexities involved in assessing individual cavity dynamic loads. Milestones for the FRIB-1 test completion, including cold mass assembly, cavity integrated tests, and low-level control, have been achieved despite resource limitations. FRIB-1 has been kept at 4 K for four months as of January 23.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

FRIB summary of performance degradation - VTA to cryomodule K. Saito MSU/FRIB SRF Development Manager This material is based upon work supported by the U.S. Department of Energy Office of Science under Cooperative Agreement DE-SC0000661, the State of Michigan and Michigan State University. Michigan State University designs and establishes FRIB as a DOE Office of Science National User Facility in support of the mission of the Office of Nuclear Physics.

FRIB Cryomodule Design Validation: ReA6 tested in FRIB Operation Conditions ReA6, 2-QWRs CM tested for final design validation of FRIB cryomodule and its subsystems Installed on a FRIB-type cryogenic distribution box QWR operation test at 4 K, in more demanding conditions than in FRIB due to larger pressure fluctuations, and at 2 K Test of all parameters and simulation of FRIB operation: Cooldow-warmup, repeated Alignment, vacuum, instrumentation Cryogenic losses Cryogenic operation SRF testing SRF subsystems performance (QWRs, tuners, RF couplers, LLRF, HLRF) Superconducting Solenoids testing Long term CM locked operation in FRIB conditions Steady state parameters measurements (cryogenics, SRF, amp-phase errors and detuning distributions, mechanical vibrations, etc ) ReA6 installed in the FRIB prototype test stand K. Saito, June 6 2016 TTC meeting WG1, Slide 2

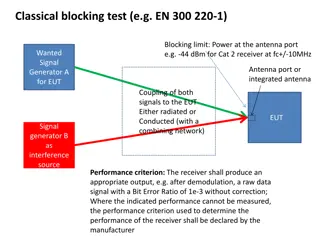

ReA6-1 Cavity Performance VT vs. Bunker Dynamic heat load was measured at Eacc = 6.2 MV/m at bunker test, which includes the coupler dynamic load (simulation 0.15W) also. Very difficult to measure individual cavity dynamic load due to small loss below the static heat load, two cavities are simultaneously measured at 2 K. Some degradation is observed in QO but not conclusive in this stage. VT at 2K Bunker at 2K QO 5.5 x 109 ~ 4 x 109 Cavity 1 Ploss [W] Eacc [MV/m] QO 1.3 ~ 2.1 6.2 6.2 Cryogenic Group 5.16 W 5.5 x 109 4.2K Operation ~ 4 x 109 SRF Group Simulation Cavity1 Cavity2 Static heat load ~ 2.1 5.5 0.57 W 4.8 W - - Cavity 2 Ploss [W] 1.3 3.1 W 3.6W Dynamic Heat load 6.2 - 6.7 W - QO > 2.7x109 at 6.2 MV/m QO > 2.3 x 109 at 6.2 MV/m Eacc [MV/m} 6.2 Cryogenic Group - 2K Operation SRF Group Simulation Cavity1+Cavity2 5.7W 5.2 W Static heat load Dynamic Heat Load 4.2W (2.1W/cavity) QO ~ 4x109 (at 6.2MV/m) 3.85W/cavity (@5.67MV/m) QO = 1.8x109 (at 2K) - 4.2 W - FRIB Goal , Slide 3 K. Saito, June 6 2016 TTC meeting WG1

FRIB 0.085QWR first Cryomodule Milestone for the FRIB-1 test completion Events Date Coldmass assembly completed 09/2015 Cryomodule assembly completed 12/2015 First cooldown started 01/23/16 Cavity integrated test 4 K completed 02/23/16 Cavity integrated test 2 K completed 03/10/16 Solenoid/magnetic shield test completed 03/18/16 Low level control test completed 05/20/16 FRIB SRF staff is working in parallel on cavity certification tests and integrated tests. The limited resources does not allow to concentrate to FRIB-1 CM test. FRIB-1 was kept at 4 K since January 23,for 4 months K. Saito, June 6 2016 TTC meeting WG1 , Slide 4

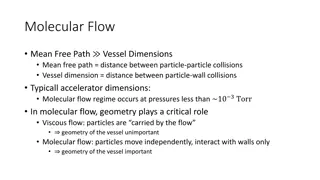

Integrated Test at 4 K/2 K with FRIB-1 Cryomodule Two cavities simultaneous operation Only two amplifiers and two low level RF control systems equipped at East highbay banker Cavity gradient (Requirement 5.6 MV/m) Result: Eacc 6 MV/m at 4 K, meets FRIB specifications, not tested at 2 K due to the limited cryo-capability in East Highbay. Cavity gradient in FRIB-1 CM at 4 K Measured dynamic Loss at Eacc = 5.6 MV/m (requirement 3.85 W/ cavity, Q0 =1.8 x 109 at 2 K) Result: 2.8 1.5 W, Q0=(2.5 1.3 ) x109 in average (included coupler dynamic heat load) at 2 K with ~ 40 % margin for FRIB spec. VT test result is (2.7 0.4) x 109 in average. No Q-degradation by cold mass assembly. Cavity Bandwidth [Hz] Q0 in VTA at 5.6 MV/m Dynamic heat Load at 2 K (W) #C1 (S85-009) 20 2.3 x109 6.2 #C2 (S85-011) 39 2.3 x109 2.4 #C3 (S85-005) 44 2.4 x109 2.5 #C4 (S85-008) 37 3.0 x109 1 #C5 (S85-003) 25 2.8 x109 2.4 #C6 (S85-004) 27 2.4 x109 2.5 #C7 (S85-006) 27 2.9 x109 2.4 More data will be collected soon #C8 (S85-007) 26 3.1 x109 2.6 Average 31 9 (2.7 x109 0.4) 2.8 1.5 K. Saito, June 6 2016 TTC meeting WG1 , Slide 5