Overview of Wastewater Treatment Units and Processes

Screening units with screens and racks remove coarse solids, comminutors reduce the size of suspended solids, and grit chambers remove sand and metal fragments from wastewater to protect downstream equipment and processes. The floatation tank removes grease, while different designs of grit chambers separate organic and inorganic solids based on their specific gravity. Specific velocities are crucial in grit chamber design to effectively remove solids. Aerated grit chambers control the separation of organic and inorganic solids through a spiral flow.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

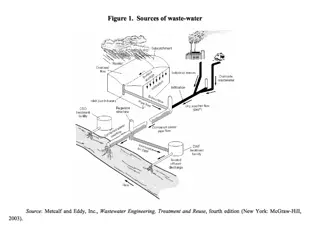

Screen and racks: Screen and racks: screening device are used to remove coarse solids from wastewater. Coarse solids consist of sticks, rags, boards, and other large objects that often find their way into sewer system. Racks are composed of parallel bars and rods with clear opening = 2.5 CM or more. Both racks and screens are cleaned mechanically or by hand.

Comminutors comminutors reduces the size of large suspended solids so that they will not harm subsequent equipment, the chopped solids are then removed in sedimentation process. Floatation tank (Skimming): Grease should be removed because they tend to plug pipes and pumps. Retention time 15 min or less. Horizontal velocity = 50 250 mm/ sec.

Grit chamber: Suspended solids such as sand, metal fragments, etc. should be removed because of their bad effect on biological treatment and mechanical equipment. Grit removal rely upon the difference in specific gravity between organic and inorganic solids to separate them. Two common design of grit chamber: a. horizontal b. aerated.

a. Horizontal grit chamber: All particles are assumed to settle in accord with newton's law: And to be scoured at a velocity 8 ? ?? ? 1 ? ? = Cd= 10, ?= 0.06, f= 0.03 , S= specific gravity. To ensure removing of inorganic without removing of organic we have to choose a horizontal velocity less than scouring velocity of inorganic and grater than scouring velocity of organic.

Ex. Grit diameter = 0.2 mm, S.G. = 2.65, Cd= 10, f= 0.03, ?= 0.06, specific gravity of organic matter= 1.1, select Vh for the basin. Sol. For inorganics: 4 3 980 10 ?? = 2.65 1 0.02 =2.1 cm/sec. 8 0.06 0.03 ? = 980 2.65 1 0.02 = 22.7 cm/sec. For organic 8 0.06 0.03 ? = 980 1.1 1 0.02 = 5.6 cm/sec.

Basin design with SOR = 2.1 cm/sec (to remove inorganic solids) Vhgreater than 5.6 cm/sec but less than 23 cm/sec. Vh= 21 Cm. b. Aerated grit chamber: It control the separation of organic and inorganic solids by producing a spiral flow. The velocity of the bulk solution is kept above the settling velocity of the organic particles, but below that of inorganic particles. Air flow is regulated to give the desired separation.

Typical design information for aerated grit chamber Parameter Range Typical Depth (m) 2 -5 Length (m) 7.5 -20 Width (m) 2.5 - 7 Width/depth 1:1 - 5:1 1.2 :1 Detention time at peak flow (min) 2 -5 3 Air supply (m3/m. min) 0.3 0.5 0.3 Grit quantity (m3 / 1000 m3) 0.004 0.2 0.015

Ex. Design an aerated grit chamber for the treatment of municipal wastewater, the average flow is 0.5 m3/sec. Assume the peaking factor is 2.75. Sol. Peak flow rate = 0.5 X 2.75 = 1.38 m3/ sec. Use two chamber Detention time at peak flow is 3 minutes Volume (each) = 1 / 2 X 1.38 X 3 X 60 = 124.2 m3 Use width / depth ratio of 2 : 1 and assume that the depth is 3 m, width = 3 Length = 124.2 / (3X3) = 13.8 m. Add 15% for inlet and outlet condition Length = 13.8 + 0.15X13.8 = 15.87 m

Determine the air supply requirement: Assume that 0.4 m3/m. min is suitable Air required = 0.4X 15.87 = 6.3 m3/ min. Estimate the quantity of grit that must be handled. Volume of grit = (0.005/1000) X 1.38X24X60X60 = 6 m3/day. Grit can be used as fill material.