Methods of Metal Forming: Rolling and Related Techniques

Rolling is a metal forming method that involves shaping metal billets between rotating rollers, utilizing friction and normal forces to deform the material. The process includes sheet rolling, slabbing, various sections of rolled metal, and different equipment used in metal forming. Other methods discussed include wire drawing, cold drawing, hot forging, and cold sheet-metal stamping.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

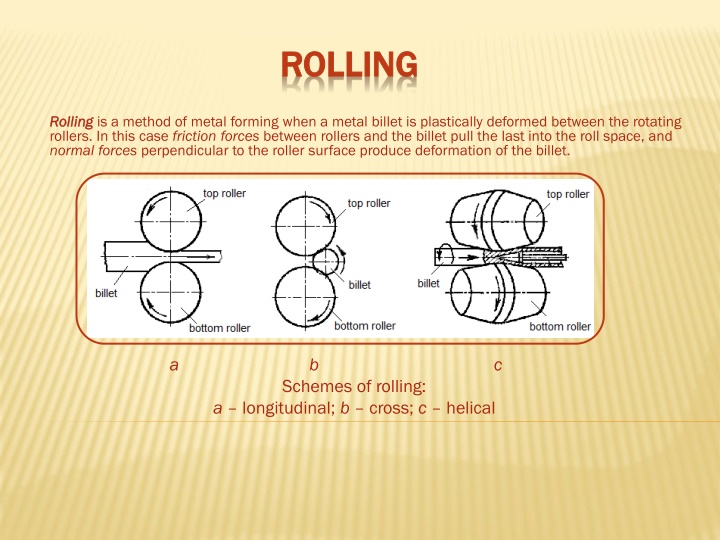

ROLLING ROLLING Rolling Rolling is a method of metal forming when a metal billet is plastically deformed between the rotating rollers. In this case friction forces between rollers and the billet pull the last into the roll space, and normal forces perpendicular to the roller surface produce deformation of the billet. a b c Schemes of rolling: longitudinal; b cross; c helical

ROLLING ROLLING Sheet rolling mill Sheet rolling mill T cos > N sin ; friction force T = N kfr, therefore N kfr cos > N sin ; kfr> tg . Rolling deformation zone Condition of roller bite of metal Condition of roller bite of metal: the coefficient of friction between the rollers : the coefficient of friction between the rollers and a billet should be higher than tangent of the angle of nip. and a billet should be higher than tangent of the angle of nip.

ROLLING ROLLING Slabbing Slabbing is a primary rolling mill for making slabs plates 2000 20 mm Single Single- -stand rolling mill: stand rolling mill: rollers; 3 3 screw screw- -down structure; 5 5 spindles; spindles; 6 6 clutches 1 1 mill housing; mill housing; 2 2 rollers; down structure; 4 4 bearings; clutches bearings;

ROLLING ROLLING a b c d e f g h i j k Sections of rolled metal Sections of rolled metal simple circle; b square; c strip; d hexagonal steel; e oval; f segmental steel; g angle; h channel; i T-beam; j I-beam; k rail simple ( ( f) f) and shaped and shaped (g (g k) k): : b b c Rollers: flat ( ) and grooved (b): 1 body; 2 roll neck; 3 roll wobbler; c pass

METHODS OF METAL FORMING Place of deformation Deformation value Name Tool Equipment Billet Heating Products Fabrication of shapes Ingot, Hot Sections, sheets, pipes, special shapes bloom, slab, intermediate product Rolling Roller opening Rolls or rollers Rolling mill deformation as a rule 2 Wire, gauged bars and pipes, shaped sections Hole of drawing die Bar, pipe, hot- rolled wire Cold Drawing Drawing die Drawing bench 1,5 deformation Simple and shaped sections, tools Ingot, hot-rolled wire Usually hot deformation Pressing Matrix hole Matrix, needle Hydraulic press = 30 50 Fabrication of billets and machine parts Ingot, Wide range of forged pieces not over 300 t Heads, laid under tools Hammers and presses Hot Forging Between heads bloom, sections of simple shape deformation FR 20 Hammers and presses, crank stamping press, upsetting machine Stamped pieces of series manufacture not over 3 t Hot Sections of simple shape Die forging Die cavity Die (stamp) deformation more often FR 2 3 Flat and volume parts having small mass and high strength Gap between punch and matrix Crank stamping press, hydraulic press Cold sheet-metal stamping Punch and matrix Cold Sheet, strip, tipe - deformation