Methods of Meat Preservation and Drying Techniques

Meat preservation is crucial to prevent microbial spoilage during distribution and storage. Methods include physical (drying, refrigeration, heat) and chemical (salting, smoking) techniques. Drying meat reduces water content, inhibiting microbial growth while prolonging shelf life. Various drying methods like sun drying, mechanical drying, and freeze-drying are used in the meat industry to produce preserved meats.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

PRESERVATION OF MEAT PRESERVATION OF MEAT Because it is high in protein and moisture, meat is an ideal medium for microbial growth, thus the preservation of meats against microbial spoilage is important during their distribution and storage. Therefore, the methods of meat preservation are based on either delay the growth of, or kill the microbes. Meat of tired or diseased animals as well as that contaminated with high numbers of spoilage microbes, are prone to rapid decomposition during preservation, hence only meat of good keeping quality should be preserved.

Methods of meat preservation can be classified into: Physical methods: Comprise drying, refrigeration (chilling & freezing), heat (canning) and irradiation. Chemical methods: Include salting, pickling, curing smoking and application of some chemical preservatives like nitrates, nitrites, sulphur dioxide, etc. Combined physical and chemical methods

Physical methods of meat preservation Physical methods of meat preservation (1) Drying of meat Preservative effect of drying is based on removing most of water content necessary for microbial growth. The average percentage of water content of dried meat is about 10% with a range of 8- 20%. In dried meats, the microbes remain inactive, cannot multiply and consequently cannot cause any deteriorative changes.

In meat industry, drying is used for the preservation and production of certain types of meats like pastrima, sausages, jerked beef, pemmican, biltong and charqui besides some animal by-products as meals (flours) of meat, bone and blood used for feeding of animals and poultry. Meat drying is usually fortified by salting and/or smoking. Dried meats are often soaked in water prior to consumption because they can easily regain water.

Methods of drying: 1- Sun (Natural) drying . 2-Mechanical drying. 3- Freeze-drying or lyophilization. 1-Sun (Natural) drying: In countries with a hot and dry climate, drying of meat can done by exposure the meat slices to the sun rays without controlled temperature, relative humidity or air drafts.

(a)Mechanical drying: Controlled-hot air driers can produce dry meats having moisture content not exceed 5%. (b)Freeze-drying or lyophilization: This is the process of removing water from slowly frozen meat (drying) by gentle heating in vacuum chamber. Sublimation (changing directly from ice to vapour without intervening liquid phase) decreases the moisture level down to 2% or my be lower.

So the freeze-dried meats possess longer shelf- life than that of mechanically-dried types. Nowadays beef, pork, chicken and shellfish are preserved by this method. The packaging of treated meats must be completely moisture- proof because the dried products are hygroscopic.

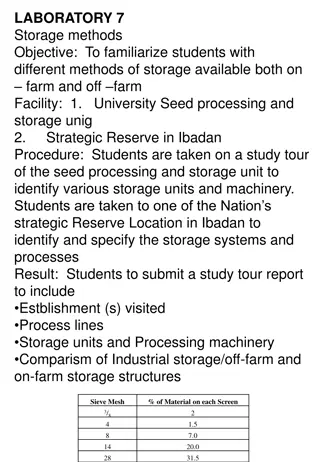

Freezing- drying machine Freeze the material Lower the pressure Increase the temperature slightly

1- Placed the material to be preserved onto the shelves when it still unfrozen when you sealed the chamber and begin the process, the machine runs the compressors to lower the temperature in the chamber. 2- The material is frozen solid, which separate the water from every thing around it, on molecular level, even though the water is still Present.

3- Next , the machine turns on the vacuum pump to force the air out of the chamber , lowering the atmospheric pressure below .06 ATM. 4- The heating units apply a small amount of heat to the shelves , causing the ice to change phase . Since the pressure is so low, the ice turns directly into water vapor 5-The water vapor flows out of the freeze- drying chamber, past the freezing coil

6- The water vapor condenses onto the freezing coil in solid ice form , in the same way water condenses as frost on a cold day . 7- This continues for many hours (even days) while the material gradually dried out 8- Once the material is dried sufficiently , it is sealed in a moisture free package , often with an oxygen absorbing material

(2) Refrigeration (Cold storage) of meat Refrigeration is the simplest and most suitable method for the preservation of meat because it can preserve meat in a condition similar to its natural state for periods commercial requirements with little change in the colour, weight and flavour. adequate for

Refrigeration prevents the multiplication of harmful bacteria, yeasts and moulds by the artificial lowering of the storage temperature. Most bacteria cannot grow at or below freezing temperature because the removal of available water as ice, about 70% is removed at -3.5 C and 94% at-10 C. therefore, at a temperature of -8 C the multiplication of all microbes stops and only regains when the temperature is raised to a suitable level.

Neither sharp nor slow freezing completely destroys the microbial contaminants found on carcasses. Mould growth on the meat surface is controlled not only by the temperature but also by the relative humidity of the cold stores. Some moulds can grow on the meat at several degrees below freezing point when the water present in the surrounding atmosphere. Therefore, for preventing mould growth on meat sufaces both temperature and relative humidity must be lowered as possible.

Methods of refrigeration: (1) Natural refrigeration (2) Mechanical refrigeration ------------------------------------------------------------ (1) Natural refrigeration (a) Cooling on or in ice (b) Cooling through ice (c) Cooling by using dry ice

Methods of refrigeration: (1) Natural refrigeration: Comprises 3 means: (a) Cooling on or in ice: Meat is refrigerated by placing it in direct contact with ice. This method is not satisfactory because the meat becomes saturated with water and moulds develop rapidly. (b) Cooling through ice: Meat is refrigerated by placing it in ice cellars having air cooled by molten ice. (c) Cooling by using dry ice: Solid carbon dioxide is used, either as solid blocks or crushed, and provides a temperature of 0 to -10 C. this method can be used in meat transport wagons. It has an additional effect for inhibiting

(2) Mechanical refrigeration: Temperature of the refrigerating chambers must be constant and adjusted either to chilling or freezing. A good circulation of fresh air is necessary (air speed over the product is 0.75-1 meter per second) and relative humidity is maintained between 88 and 92%. Humidity levels above this range promote slime formation and mould growth, while lower values increase moisture loss during chilling; the undesirable feature for both economic reasons and eating quality.

In meat-carrying ships, the pipes containing ammonia are immersed in tanks of brine (calcium chloride solution), the resulting cold solution is circulated in pipes around the refrigerating chambers.

Criteria and precautions of refrigeration: Criteria and precautions of refrigeration: For obtaining of effective chilling and freezing of meats as well as the prevention of microbial growths causing spoilage and food poisoning, The following criteria must be adopted: (1)Initial design of refrigeration space should consider the size of individual units, rail height besides floor and wall surfaces. (2)Temperature must be checked regularly.

(3) Overloading should be avoided and carcasses must not touch each other. (4) Door opening and closing must be kept to a minimum. (5) Adequate air flow around carcasses is essential. (6) Carcasses of different species must not occupy the same area. (7) Cold shortening should be avoided by initial chilling of carcasses at not less than 5 C for the first 24 hours after dressing.

Cold shortening Cold shortening is the result of the rapid chilling of carcasses immediately after slaughter, before the glycogen in the muscle has been converted to lactic acid. With glycogen still present as an energy source, the cold temperature induces an irreversible contraction of the muscle (i.e., the actin and myosin filaments shorten). Cold shortening causes meat to be as much as five times tougher than normal. This condition occurs in lean beef and lamb carcasses that have higher proportions of red muscle fibers and very little exterior fat covering. -

Without the fat covering as insulation,the muscles can cool too rapidly before onset of rigor mortis. The process of electrical stimulation (the application of high-voltage electrical current to carcasses immediately postmortem) reduces or eliminates this condition by forcing muscle contractions and using up muscle glycogen. Thaw rigor is a similar condition that results when meat is frozen before it enters rigor mortis. When this meat is thawed, the leftover glycogen allows for muscle contraction and the meat becomes extremely tough.

Chilling of meat For preserving the quality, bloom and weight of meat, it is important to begin chilling as soon as possible after dressing. For initial chilling of warm carcasses, sides or quarters, the temperature must be maintained at 5 C, while in the terminal chilling kept between -7 and +2 C. The carcasses should not be subjected to very low temperature or very high air circulation for the first 24 hours, thus the temperature maintained at not less than 5 C with an air speed of not more than 1 meter/second for this period. Lower temperatures and higher air speeds induce cold shortening.

Therefore, the meat exporters prefer to export chilled beef kept at -1.1 C (slightly above the freezing point) and preferably in the dark, because the light accelerates fat oxidation and production of rancidity Although bacterial growth is usually inhibited at this chilling room temperature, the meat continues to lose water by evaporation, and the surrounding air, becoming humid, creates a suitable condition for the mould growth.

Therefore, the atmosphere must be kept dry to hinder the formation of mould growths which are more often attack chilled meat than frozen. The storage life of this chilled beef is only 35 days. After this time deterioration becomes apparent (mould growth, bacterial slime and putrefaction).

When the air of chill rooms contains 10% CO2, the storage life of meat at 0 C is double that of meat stored in ordinary air at a similar temperature, and by this method the storage life of chilled meat is extended to 60-70 days enabling its exportation to distant countries in excellent condition.

Changes in chilled meat: (1) Conditioning, ripening or maturation: (2) Loss of weight (Shrinkage ) (3) Soiling (4) Sweating (condensation of water vapour ) (5) Absorption of foreign odours (6) Microbial spoilage

(1) Conditioning, ripening or maturation: This change is characterized by marked increase in tenderness, juiciness and flavour of chilled meat. This done by autolytic proteolysis which will stop under freezing temperatures. (2) Loss of weight (Shrinkage): Chilled meat usually loses 1.5-2% of its weight during the first 24 hours of chilling due to moisture loss, later on further losses will depend on the ambient relative humidity. More moisture loss causes excessive shrinkage which results in a dry, dark and unattractive surface. Therefore, the relative humidity of the chilling rooms must be maintained at 90%.

(3) Soiling: Chilled meat can be soiled by microbial contaminants come from the dirty workers and adjacent carcasses. (4) Sweating (condensation of water vapour): Condensation of water vapour on the surface of chilled meat brought from a cold store into an ordinary room temperature occurs because the cold carcass lowers the temperature of surrounding air to below the dew point. If the chilled quarter or side is cut up immediately after removal from the cold store, the sweating will extend to the individual joints.

(5) Absorption of foreign odours: Meat easily absorbs the odours of strong smelling substances like disinfectants (carbolic acid and formalin), ammonia, fruits, vegetables and fish. Ozonization may be recommended to deodourize the abnormal odours of chilling rooms. (6) Microbial spoilage: a) Mould growths: b) Bacterial spoilage:

a) Mould growths: They are the most common type of spoilage in chilled meat. Mould growths on chilled meat can be prevented contamination of meat surface with mould spores, lowering the relative humidity to a minimum as well as by fumigating the cold stores by sulphureous acid gas or formalin vapour prior to meat chilling. by reducing the

b) Bacterial spoilage: Although mould growths are the commonest type of microbial spoilage in chilled meat, bacteria of the A chromobacter bacteria may spoilage meat because they can grow at 0 C. The affection appears as small glistening brown droplets which eventually coalesce to form a brownish slime on the meat surface with the production of a characteristic sour odour (cold store taint); the slime frequently becomes visible when the bacterial numbers exceed 30 millions/cm2