Mechanical Contributions & Installation Sequences for Cathode Assembly in DUNE Project

This document outlines the tools, area requirements, and installation sequence for the cathode assembly, routing, and testing in the DUNE project. It covers tool lists, area estimates, shipping box specifications, handling instructions, and equipment needed for ground and underground operations. The focus is on the Cathode Assembly Routing Testing Wall (CARTW) setup in the grey room and outside the cryostat, emphasizing the vertical assembly, fiber routing, and testing procedures.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

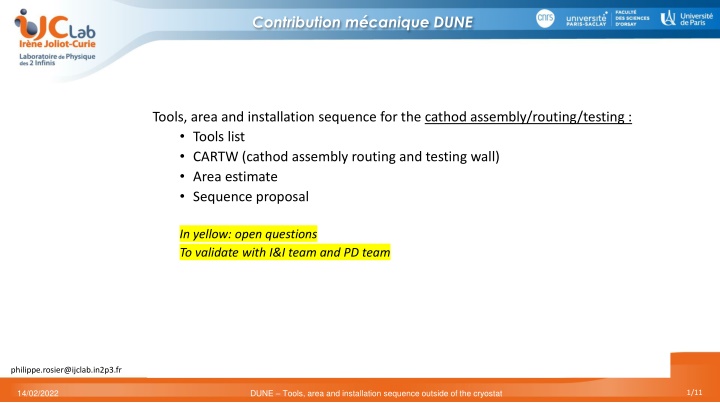

Contribution mcanique DUNE Tools, area and installation sequence for the cathod assembly/routing/testing : Tools list CARTW (cathod assembly routing and testing wall) Area estimate Sequence proposal In yellow: open questions To validate with I&I team and PD team philippe.rosier@ijclab.in2p3.fr 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 1/11

Shipping Box size to fit in the lift cage: Shipping Box size to fit in the lift cage: principle principle 100 foam 50 shell 1 box = 3 frames = super cathode 100 foam 50 shell 50 shell 100 foam 2350 mm external size 6 half frames stacked = 950 mm external size 100 half frames connect.links 2988,3 CAGE LIFT SIZES 1683 Option Rotation axis Option Rotation axis 100 foam 100 shell 200 wood bars 3300 mm external size Side view Box in horizontal position for shipment In vertical position just in the lift cage 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 2/11

Shipping Box Shipping Box specifications specifications 3300 x 2350 x 1085 mm3 Total mass 730 Kg Including 250 Kg of frames Equipped of lifting rings or rotation axis I&I constraints ? How to handle and rotate this box ? 20 or 60 m cables !! With bending radius Fibers mounted on the CARTW !! 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 3/11

Tools Tools needed needed on on ground ground and/or underground and/or underground (to (to validate validate with withITs ITsand set the design and set the design details details) ) With a crane: Lifting beam + rotation axis Or slings + lifting rings ? Forklift In the cryostat: Transfer tables with rollers ? Mounting tables or the super cathod Scissor lift for the CARTW With a crane: Lifting beam + rotation axis Or slings + lifting rings ? And rollers in the cage lift ? 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 4/11

Definition Definition of a of a Cathod Cathod Assembly Assembly RoutingTesting RoutingTesting wall wall (CARTW) (CARTW) IN THE GREY ROOM The assembly, fiber routing and testing are done in vertical position (to validate with PD team) This is convenient for any arapuca configuration (perimeter or central positions) It permits to access on the 2 faces of a cathod and on the sides The wall is 4 m height x 4 m long x 2 m width It has to be screwed in the ground to secure the vertical position This wall could be IJCLAB designed but purchased directly in the USA and mounted underground. A crane with lifting beam helps the transfer of elements => Own gantry to provide A scissor lift helps the work and access in height (Floor up to 1,8 m mini) It is installed in a grey room with climate and ventilation (glue vapors) + all fiber routing and testing equipments 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 5/11

Frame Frame assembly assembly and and glueing glueing operations operations on the CARTW on the CARTW 2 half frames of 1,7 x 3 m are transferred out from the shipping box They have been : - precabled with arapuca fibers, - equipped of their cross ribs - equipped of their meshes except on arapuca squares 40 kg each half before glueing If visual inspection is satisfactory The bottom half is installed on the CARTW. Glue is applied on the top boundary. The top half is lift with a crane and slide on the bottom boundary for glueing and screwing 40 kg each half before glueing 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 6/11

Grey room Grey room equipped equipped with with 3 CARTW 3 CARTW Arapuca and mesh mounted Ready for fiber testing Frame ready for arapuca mounting Frame ready for arapuca mounting 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 7/11

Top view Top view of the grey room => of the grey room => 2 grey rooms needed 2 grey rooms needed or more depending of the PD test or more depending of the PD test Grey room : Testing station Testing station Testing station Area 8x8 m ceiling height: 5 m mini 2,5 m CARTW 1 CARTW 2 CARTW 3 Anti-dust Glue vapor extraction 20 C ambient temperature Crane lifting (incorporated in the cartw) cathod cathod scissor lift cathod 4 m 8 m scissor lift scissor lift scissor lift Wide opening door Cold test !! UNIT ASSEMBLY WALL instead of 3 ??? Cathod door 8 m 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 8/11

Cold box test in clean area Cold box test in clean area Arapuca power over fiber need to be checked Done for FD1 for APA 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 9/11

Transfer to the cryostat in vertical position Transfer to the cryostat in vertical position One equipped frame with arapuca What about the transfer through the TCO ? Change of crane ? Temporary station in horizontal or vertical position ? We need input from the I&I to define the process TCO beam available then we can just provide rotation axis 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 10/11

Sequence Sequence summary summary : Phases, area and : Phases, area and tooling tooling (1/2) (1/2) Object: 80 frames (160 half frames) Shipping box for 3 frames : 3300 x 2350 x 1085 mm3 / Total mass 730 Kg Including 250 Kg of frames => 27 box shipped in horizontal position Shipping schedule ?? : 30 in 2024, 30 in 2025, 20 in 2026 (Ground logistic volume ? where will it be stored on ground and/or underground ?) CHECK LYDIA GROUND GROUND Phase : Tools = Forklift Transfer in horizontal position Area = 300 m mini for 30 box CAGE LIFT Phase: Tools = lifting beam+rotation axis ? / slings / rollers ? Rotation of the box from Horizontal to Vertical position before getting in the cage Transfer with rollers to move in/out the cage ?? Rotation of the box from Vertical to Horizontal position after getting out the cage Area = 25 m Process to validate with I&I constraints UNDERGROUND Box storage: When (2026/2027) ? Tools= lifting beam and crane / Forklift ? Transfer in horizontal position Storage box ? (AREA ???) Area = 40 m min for a super cathod (2 box) UNDERGROUND Underground logistic volume ?? UNDERGROUND Box opening : Tools= lifting beam and crane Opening to extract the frames (6 half frames) each IN a CLEAN BAG Transferred directly to CARTW in grey room => need a cart table Area = 20 m min 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 11/11

Sequence Sequence summary summary : Phases, area and : Phases, area and tooling tooling (2/2) (2/2) UNDERGROUND Frames assembly ang glueing Tools= lifting beam and crane / Cissor lift Transfer on the assembly wall in vertical position Positionning the bottom half glue addition Positionning the top half After 12 h curing => tests or unloading/transfer 1 days for 6 frames Area = 70 m min each grey room => 2 grey rooms depend of PD tests UNDERGROUND in the grey room UNDERGROUND Arapuca, Fiber and Mesh mounting Tools= Cissor lift Arapuca insertion in the frame Fiber routing completion Fiber connection tests (How many hours for the testing ?)(COLD BOX tests) Mesh final mounting UNDERGROUND UNDERGROUND to the cryostat UNDERGROUND Transfer towards the cryostat Tools= lifting beam and crane Transfer in vertical position Process through TCO ? Area = 16 m min per cathod to the cryostat UNDERGROUND In the cryostat Tools= lifting beam and crane / mounting tables Rotation of the frame from Vertical to Horizontal position after getting in the cryostat => Drive with rolling table to SSC positions ?? Installation on mounting tables 14/02/2022 DUNE Tools, area and installation sequence outside of the cryostat 12/11