Lockout/Tagout Safety Procedures

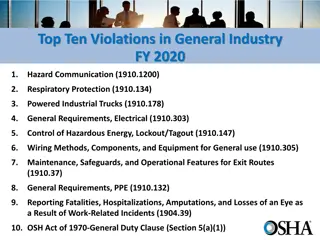

In industrial settings, lockout/tagout procedures are crucial for preventing accidents related to hazardous energy sources. Authorized employees must evaluate, identify, and control energy sources to avoid unexpected startups or energy releases. These procedures cover servicing, maintenance, and normal operations, with a focus on safety measures to protect employees. An energy control program, preparation for shutdown, and specific shutdown procedures are essential elements of effective lockout/tagout practices.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Lockout/Tagout Authorized Employees

Hazardous energy sources Evaluate machines, equipment, and processes Develop energy control plan 1a

Hazardous energy sources Look for all sources of energy Identify secondary and stored energy sources 1b

Why lockout/tagout is necessary Prevents injury due to unexpected startup of equipment or released energy Maintenance/ servicing operations often require employee to place part or all of his/her body into machine s point of operation 2a

Functions covered by lockout/tagout Servicing of machines and equipment Performing maintenance on equipment and machinery Normal operations 3a

Energy control program Authorized employees Affected employees Other employees 4a

Energy control program Energy control procedures Training Periodic audits 4b

Preparation for shutdown Locate all energy sources Inform all affected persons 5a

Shutdown procedure Each piece of equipment or machine must be shutdown according to written energy control procedures Orderly shutdown avoids additional or increased hazards 6a

Shutdown procedure Use shutdown procedures that are established for the machine 6b

Isolating machinery from its energy sources Type of devices to be used Placement of isolating devices 7a

Application of lockout/tagout devices Positioning of lockout/tagout devices Only authorized employees can attach the devices 8a

Releasing stored energy Check for and relieve: electrical energy capacitors residual pressure in lines and pipes 9a

Verification procedures Verify that all locks and tags are in place Try to operate the equipment 10a

Lockout devices Types used Standardized for easy recognition 12a

Lockout devices Never use someone else s lockout device The lock must identify the person who applied it 12b

Tags Types used Standardized for easy recognition 13a

Tags The attachment means for a tag must be: non-reusable attachable by hand self-locking and non-reusable with locking strength of 50 pounds equivalent to a one-piece, all- environment-tolerant nylon cable tie 13b

Tags The tag s legend must include the following types of statements: 13c

Group lockouts Uses group lockout devices (hasps) to accommodate all locks Each authorized employee must affix a personal lockout or tagout device to the group lockout device when he/she begins work hasp 14a

Group lockouts Each authorized employee must remove those devices when he/she stops working on the machine/ equipment 14b

Shift changes The first employee s lock remains in place until the next shift s employee applies his/her lock 15a

Removing a lock If an employee is not available to remove a lock, the employer must: verify that the employee is not in the facility make reasonable efforts to contact the employee inform the employee of the removal before he/she resumes work 16a

Restoring energy to the equipment/machine Remove tools from the area, replace guards Ensure that employees are safely positioned or removed from the area 17a

Restoring energy to the equipment/machine The employee who applies the lock is the only one who can remove it Special requirements for testing and positioning equipment 18b