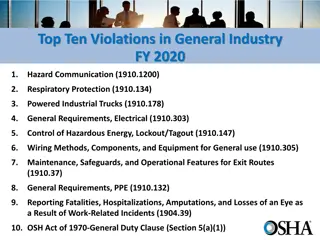

Hazardous Energy Control with Lockout/Tagout Standard

Prevent injuries related to hazardous energy by implementing Lockout/Tagout standard procedures for equipment maintenance. Lockout techniques involve isolating energy sources and using padlocks to ensure machinery stays off during servicing, reducing the risk of unexpected injuries from energy release.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level LOCK OUT/TAG OUT LOCK OUT/TAG OUT

29 CFR 1910.147 Click to edit Master text styles Second level Third level Fourth level Control of Hazardous Energy Control of Hazardous Energy Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level

OVERVIEW OVERVIEW Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level in the equipment. Click to edit Master text styles Second level Third level Fourth level machinery or equipment, or release of stored energy Workers performing service or maintenance on machinery and equipment are exposed to injuries from the unexpected energization, startup of the ON ON OFF OFF

LOCK OUT LOCK OUT TAG OUT TAG OUT Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level from escaping. Click to edit Master text styles Second level Third level Fourth level the hazardous energy Lockout is a technique used to prevent the release of hazardous energy, or to prevent A padlock is placed on the appropriate energy isolating device that is in the off or closed position.

Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level 3 3 Click to edit Master text styles Second level Third level Fourth level 2 2 1 4 4 5 5

LO LO- -TO STANDARD TO STANDARD Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level activities are being performed. Click to edit Master text styles Second level Third level Fourth level hazardous energy while maintenance and servicing The Lockout/Tagout standard requires the adoption and implementation of practices and procedures to shut down equipment, isolate it from its energy source(s), and prevent the release of potentially It contains minimum performance requirements, and definitive criteria for establishing an effective program for the control of hazardous energy. However, employers have the flexibility to develop lockout/tagout programs that are suitable for their respective facilities.

Scope and Application Scope and Application Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Who does this standard apply to? General Industry workers performing servicing and maintenance on machines and equipment and who are exposed to the unexpected energization, startup, or release of hazardous energy.

Definitions Definitions Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Electrician, Plumber, HVAC Mechanic, Maintenance Worker. Authorized Employee - one who locks out machines or equipment in order to perform the servicing or maintenance on that machine or equipment. Affected Employee - one whose job requires him/her to operate or use a machine or equipment on which servicing or maintenance is being performed under lockout, or whose job requires him/her to work in an area in which such servicing or maintenance is being performed. Custodian, Teacher, Kitchen Worker.

Definitions, cont.. Definitions, cont .. Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Energy Isolating Device - A mechanical device that physically prevents the transmission or release of energy. http://www.lockoutdevices.co.uk/xenoy%20safety%20padlocks.jpg Energy Control Procedure - Safety program adopted by the employer that includes energy control procedures plus provisions for inspecting the procedures and training employees for lock out/tag out.

ACTIVITIES COVERED ACTIVITIES COVERED Click to edit Master text styles Second level Third level Fourth level Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level

Hazardous Energy Sources Hazardous Energy Sources Found in the Workplace Found in the Workplace Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Electrical Generated Static Mechanical Transitional Rotational Thermal Machines or Equipment Chemical Reactions Potential Pressure Hydraulic Pneumatic Vacuum Springs Gravity Lockout / Tagout Valve tagout

DESCRIPTION DESCRIPTION Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level release of hazardous energy. Servicing and maintenance activities performed during normal production operations if: An employee is required to remove or bypass machine guards or other safety devices, or An employee is required to place any part of his or her body into a point of operation or into an area on a machine or piece of equipment where work is performed, or into the danger zone associated with the machine's operation. Click to edit Master text styles Second level Third level Fourth level energization or startup of the equipment or Constructing, installing, setting up, adjusting, inspecting, modifying, maintaining and/or servicing machines or equipment, including lubrication, cleaning or un-jamming of machines or equipment, and making adjustments or tool changes, where employees could be exposed to the unexpected

Who does this Who does this standard not apply to? standard not apply to? Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level energization or startup of the machines or equipment, or the release of hazardous energy. General Industry workers performing servicing and maintenance on machines or equipment who are NOT exposed to the unexpected

Lockout Procedure Lockout Procedure Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Equipment Shutdown Alert the operator power is being disconnected. Preparation for Shutdown Equipment Isolation Application of Lockout Devices Control of Stored Energy Equipment Isolation-Verification

Removal of Lockout Removal of Lockout Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Remove lockout/tagout devices. Ensure equipment is safe to operate Safeguard all employees Last person to take off lock Follow checklist

Temporarily Temporarily Reactivating Equipment Reactivating Equipment Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Click to edit Master text styles Second level Third level Fourth level Remove unnecessary tools from the work area and make sure everyone is clear of the equipment As soon as the energy is no longer needed, isolate the equipment and re-apply lockout/tagout, using the six step procedure. Remove lockout/tagout devices and re-energize the system

Special Situations Special Situations Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level service or maintenance at your workplace Worker who applied lock is not available. Click to edit Master text styles Second level Third level Fourth level Contractors are performing Servicing lasts longer than one shift.

Additional Info Additional Info Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level Never loan or share your lock, combination, or key with anybody else. Click to edit Master text styles Second level Third level Fourth level Program. Never attempt lockout/tagout procedures unless you have been trained and certified by your employer under an approved Energy Control Always be sure all lockout/tagout devices are compatible with the environment in which they will be used i.e. corrosive, humid, etc.

ANY QUESTIONS? ANY QUESTIONS? Click to edit Master text styles Second level Third level Fourth level Click to edit Master text styles Second level Third level Fourth level Fifth level Fifth level