Laser Ignition Technology for Improved Engine Combustion

Internal combustion engines rely on ignition systems for optimal performance. Laser ignition technology offers advantages over conventional spark plugs, addressing drawbacks and enhancing combustion efficiency.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

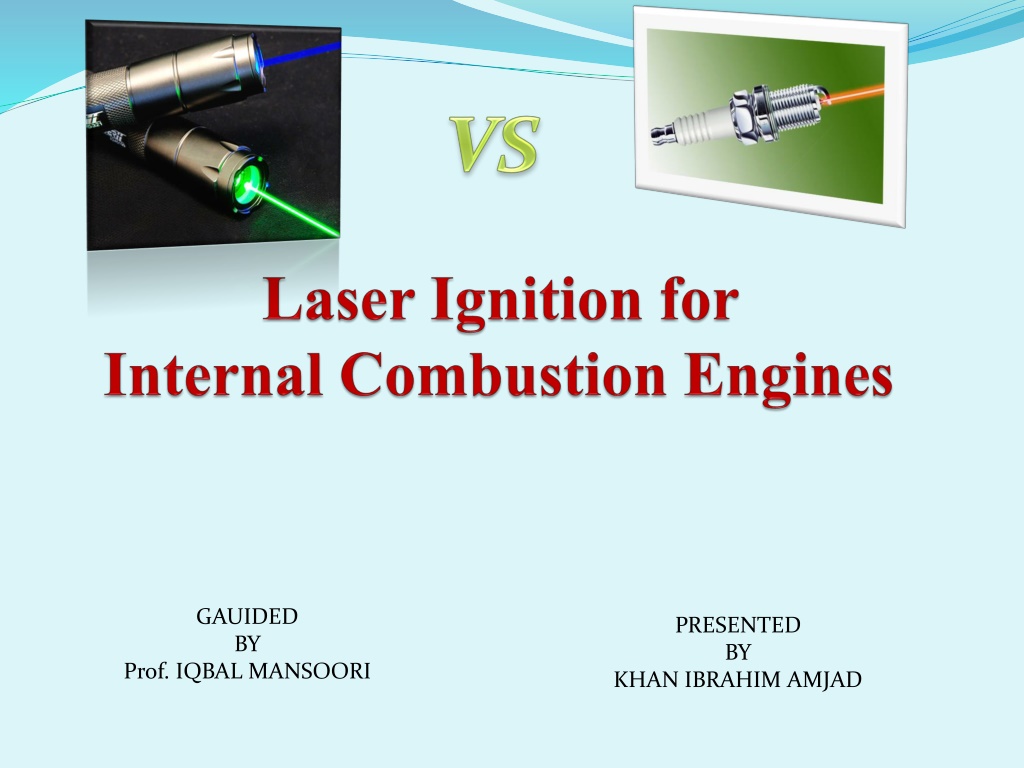

GAUIDED BY PRESENTED BY KHAN IBRAHIM AMJAD Prof. IQBAL MANSOORI

CONTENTS INTRODUCTION CONVENTIONAL SPARKING PLUG IGNITION DRAWBACKS OF CONVENTIONAL IGNITION SYSTEM WHAT IS A LASER? LASER Ignition Types of Laser Ignition SETUP OF LASER IGNITION Working principle FLAME PROPAGATION IN COMBUSTION CHAMBER Why Laser Ignition? Comparative Advantages of Laser Ignition Additional advantages of Laser Ignition COMPERISION S.P AND L.I Future Research Needs and Shortcomings Summary Conclusion REFERENCES

INTRODUCTION Internal combustion engines play a dominant role in transportation and energy production. In technical appliances such as internal combustion engines, reliable ignition is necessary for adequate system performance. Unfortunately, conventional spark plug ignition shows a major disadvantage with modern spray-guided combustion processes since the ignition location cannot be chosen optimally. A laser ignition source has the potential of improving engine combustion with respect to conventional spark plugs.

CONVENTIONAL SPARKING PLUG IGNITION Conventional spark plug ignition has been used for many years. For ignition of a fuel-air mixture the fuel-air mixture is compressed and at the right moment a high voltage is applied to the electrodes of the spark plug.

Standard Spark Plug Ignition in an Internal Combustion Engine Current internal combustion gasoline engines use spark plugs to ignite the air/fuel mixture in each cylinder (located at the top of the combustion chamber).

DRAWBACKS OF CONVENTIONAL IGNITION SYSTEM Location of spark plug is not flexible as it requires shielding of plug from immense heat and fuel spray. Leaner mixtures cannot be burned, ratio between fuel and air has to be within the correct range. Flame propagation is slow. Erosion of spark plug electrodes. Degradation of electrodes at high pressure and temperature.

WHAT IS A LASER? Alaser is a device that emits electromagnetic radiation through a process of optical amplification based on the stimulated emission of photons. The term laser is an acronym for Light Amplification by Stimulated Emission of Radiation

LASER Ignition Laser ignition, or laser-induced ignition, is the process of starting combustion by the stimulus of a laser light source. Laser ignition uses an optical breakdown of gas molecules caused by an intense laser pulse to ignite gas mixtures. The beam of a powerful short pulse laser is focused by a lens into a combustion chamber and near the focal spot and hot and bright plasma is generated, see fig.

Types of Laser Ignition Basically, energetic interactions of a laser with a gas may be classified into one of the following four schemes as described in 1. Thermal initiation 2. Non-resonant breakdown 3. Resonant breakdown 4. Photochemical mechanisms

Laser Ignition System for an Internal Combustion Engine Laser ignition will replace the spark plug seen in current gasoline engines.

Working principle The laser ignition system has a laser transmitter with a fiber-optic cable powered by the car s battery. It shoots the laser beam to a focusing lens that would consume a much smaller space than current spark plugs. The lenses focus the beams into an intense pinpoint of light, and when the fuel is injected into the engine, the laser is fired and produces enough energy (heat) to ignite the fuel. Below is a diagram of the laser arrangement:

FLAME PROPAGATION IN COMBUSTION CHAMBER

Why Laser Ignition? Regulations on NOx emissions are pushing us toward leaner air/fuel ratios (higher ratio of air to fuel). These leaner air/fuel ratios are harder to ignite and require higher ignition energies. Spark plugs can ignite leaner fuel mixtures, but only by increasing spark energy. Unfortunately, these high voltages erode spark plug electrodes so fast, the solution is not economical. By contrast, lasers, which ignite the air-fuel mixture with concentrated optical energy, have no electrodes and are not affected. Natural gas is more difficult to ignite than gasoline due to the strong carbon to hydrogen bond energy. Lasers are monochromatic, so it will be much easier to ignite natural gases and direct the laser beam to an optimal ignition location. Because of the requirement for an increase in ignition energy, spark plug life will decrease for natural gas engines. Laser spark plug ignition system will require less power than traditional spark plugs, therefore outlasting spark plugs. Ignition sites for spark plugs are at a fixed location at the top of the combustion chamber that only allows for ignition of the air/fuel mixture closest to them. Lasers can be focused and split into multiple beams to give multiple ignition points, which means it can give a far better chance of ignition.

Why Laser Ignition? (continued) Lasers promise less pollution and greater fuel efficiency, but making small, powerful lasers has, until now, proven hard. To ignite combustion, a laser must focus light to approximately 100 gigawatts per square centimeter with short pulses of more than 10 millijoules each. Japanese researchers working for Toyota have created a prototype laser that brings laser ignition much closer to reality. The laser is a small (9mm diameter, 11mm length) high powered laser made out of ceramics that produces bursts of pulses less than a nanosecond in duration. The laser also produces more stable combustion so you need to put less fuel into the cylinder, therefore increasing efficiency. Optical wire and laser setup is much smaller than the current spark plug model, allowing for different design opportunities. Lasers can reflect back from inside the cylinders relaying information such as fuel type and level of ignition creating optimum performance. Laser use will reduce erosion.

Comparative Advantages of Laser Ignition Spark ignition system Laser ignition system Less intense spark More intense spark Leaner mixtures cannot be burned Leaner mixture can burn effectively Flame propagation is slow Flame propagation is faster Multi point fuel ignition is not feasible. Easier possibility of multipoint ignition. It causes more NOx emission Less NOx emission

Additional advantages of Laser Ignition: It does not require maintenance to remove carbon deposits because of its Self cleaning property. Precise ignition timing possible. High load/ignition pressures possible => increase in efficiency. Easier possibility of multipoint ignition.

COMPERISION S.P AND L.I 110 100 Spark ignition between fuel spray Laser ignition between fuel spray Laser ignition within fuel spray (Percent) 90 80 Consumption Smoothness Emissions

Future Research Needs and Shortcomings Cost Concept proven, but no commercial system yet available. Stability of optical window Beam Delivery/Laser induced optical damage Particle Deposits Intelligent control Laser Distribution Multiple pulse ignition Multiple point ignition Single Point Ignition: Timing optimization (phasing) vs Thermal Efficiency NOx tradeoffs Knock margin Multipoint Ignition: Higher flame speed may provide additional knock margin as well as a higher burn rate. Multipulse Ignition: May provide improved ignition, leaner combustion, and lower emissions. May provide a way to circumvent beam delivery issue.

Summary Laser Ignition has the potential to greatly improve existing and future artillery systems. Safer Environmentally Friendly Reliable Automated Operation Technology Driven System Improvements Versatile and Flexible

Conclusion Laser ignition system allows almost free choice of the ignition location within the combustion chamber, even inside the fuel spray. Significant reductions in fuel consumption as well as reductions of exhaust gases show the potential of the laser ignition process. Laser ignition is nonintrusive in nature; high energy can be rapidly deposited, has limited heat losses, and is capable of multipoint ignition of combustible charges.

REFERENCES http://www.laserist.org/Laserist/showbasics_laser.html Bergmann and Schaefer, Lehrbuch der Experimentalphysik: Elektrizit at und Magnetismus, vol. 2, Walter de Gruyter Berlin, 1981 D. R. Lidde, ed., CRC Handbook of Chemistry and Physics, CRC Press, 2000 International Journal of Science and Research (IJSR) Volume 3 Issue 7, July2014. J.D. Dale, P.R. Smy, R.M. Clements, Laser Ignited Internal Combustion Engine An Experimental Study, S.A.E. Conference in Detroit, 29March 1978 Ma J.X., Alexander D.R., Poulain D.E., Laser spark ignition and combustion characteristics of methane-air mixtures, Combustion and Flame 112, 492-506 (1998).