Lactic Acid Fermentation in Food Industry

Lactic acid fermentation is a widely used method for producing fermented foods like dairy, vegetables, and meats. This process involves lactic acid bacteria and filamentous fungi to convert sugars into lactic acid. Various microbial cultures are utilized, and raw materials such as whey, molasses, and starchy materials are common substrates. Different fermentation methods like batch, fed-batch, and continuous are employed in industrial production, with batch fermentation being the most common due to its simplicity.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

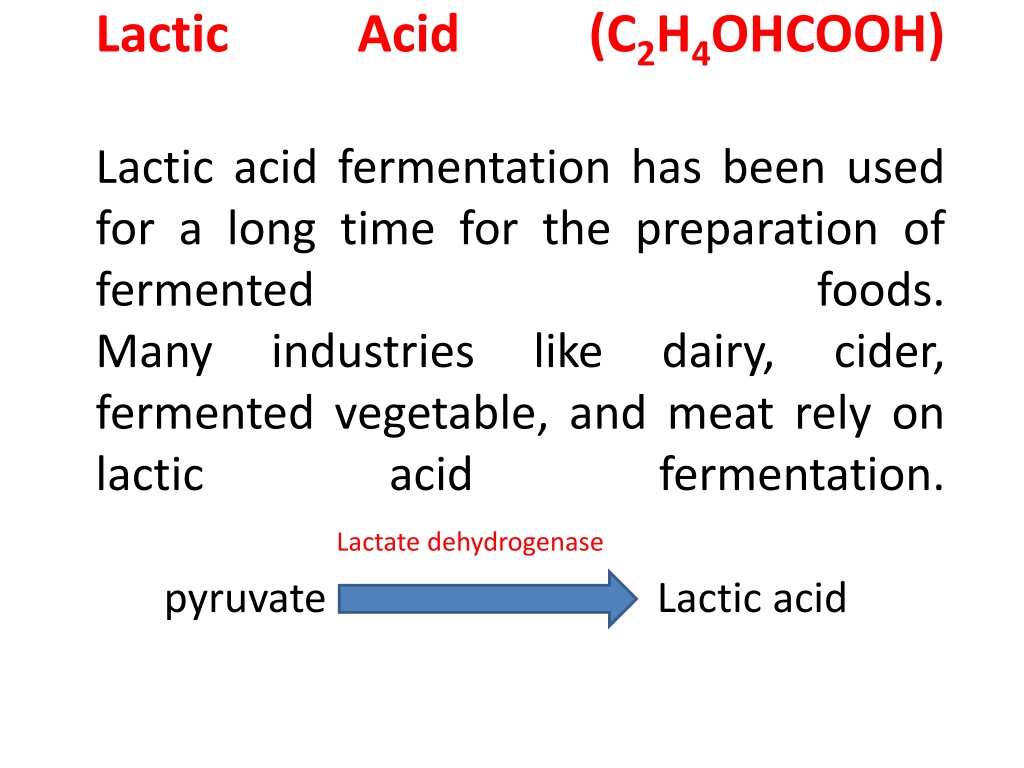

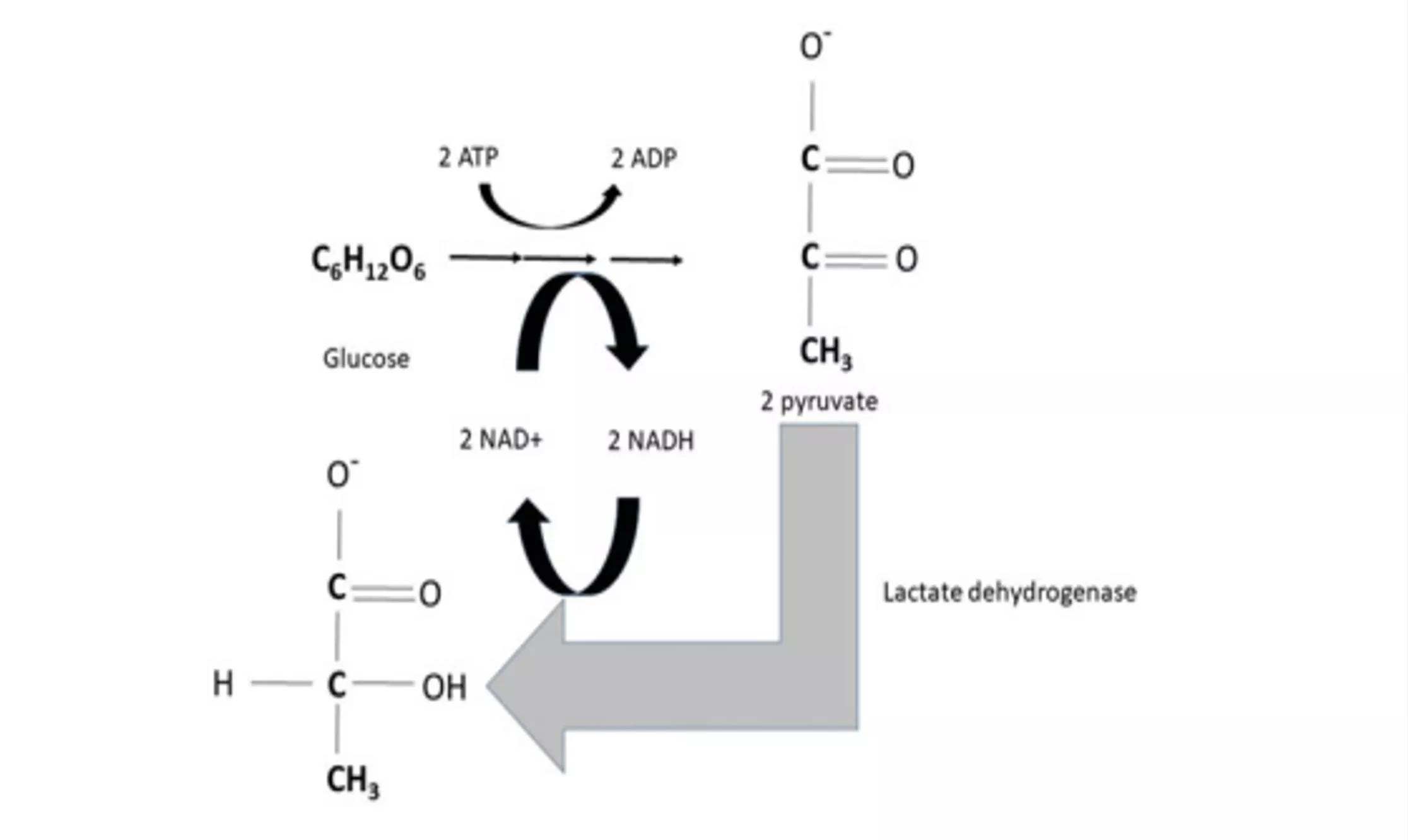

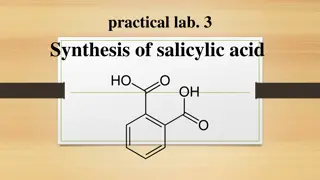

Lactic Acid (C2H4OHCOOH) Lactic acid fermentation has been used for a long time for the preparation of fermented Many industries fermented vegetable, and meat rely on lactic acid foods. cider, like dairy, fermentation. Lactate dehydrogenase pyruvate Lactic acid

Microbial cultures in lactic acid production The lactic acid production was carried out by using microorganisms such as lactic acid bacteria (LAB), and filamentous fungi, e.g. Rhizopus oryzae. Most of the lactic acid production is done industrially by the use of lactic acid bacteria.

Lactic acid bacteria Lactic acid bacteria are generally gram- positive bacteria. They are non-motile, have non-spore-forming rods and cocci. Lactic acid bacteria grow under anaerobic conditions , produce lactic acid as the major product from the energy-yielding fermentation of sugars . The LAB genera Lactobacillus, Lactococcus, Streptococcus, Enterococcus, Pediococcus. generally included Leuconostoc,

Based on fermentation pathways, LAB can be sub- devided into two groups, homofermentative or heterofermentative. where lactic acid is produced as the major or only end- product : homolactic metabolism, 85-90% LA *other end-products including CO2and ethanol are produced during heterolactic metabolism 50% LA - Homofermentative LAB Lactococcus, Enterococcus, Pediococcus -Heterofermentative LAB Leuconostoc. include Streptococcus, include Weissella and

Raw materials for lactic acid production Whey and molasses, which are industrial wastes, are commonly used as substrates for lactic acid production. Also, the cheap raw material sources for the production of lactic acid: Starchy materials such as corn, potato, rice, and wheat starch, and cellulosic materials such as wood.

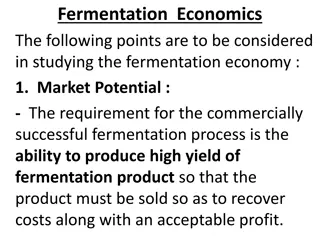

Fermentation process: Three different methods of fermentation are practiced in lactic acid production, namely, 1-Batch fermentation, 2-Fed-batch fermentation, and 3-Continuous fermentation. Batch fermentation process is the most commonly practiced fermentation process as it is simple. process the culture is first grown in a series of inoculums vessels and after that transferred to the fermentor. The size of inoculum is usually 5-10% of the liquid volume in this fermentor. The fermentation is usually kept at 35-45C and at pH 5- 6.5 by adding a suitable base, such as ammonium hydroxide. In this

Fermentation takes 1-2 days under optimal lab conditions. Conditions for fermentation are different for each industrial method but are usually in the 45 C having a pH of 5-6.5 for Lactobacillus delbrueckii. Productivity is affected fermentation time and the level of substrate. The yield of lactic acid after the fermentation stage is 90-95 wt% based on the initial sugar or starch concentration. Y%=Produced lactic acid/ sugar(g)*100 by temperature,

Purification or product recovery Purification or product recovery is an important step in lactic acid production . Fermentation broth contains a number of impurities such as residual sugars, color, nutrients and other organic acids, as part of cell mass. These impurities must be removed from the broth in order to achieve more pure lactic acid . To recover and purify the lactic acid produced from the microbial fermentation media, using ion exchange chromatography , it gives product recovery at very low cost within a short period of time.

Types of purified lactic acid Technical grade lactic acid .It is 44-45% total acidity.(higher content of contaminated sugar ,metal,chloride ,sulphate ,ash Food grade acid has a total acidity of about 50%. It is made from the fermentation of higher grade sugar and bleached with activated carbon. Plastic grade (80%) is obtained by esterification with methanol after concentration. High-grade lactic acid (pharmaceutical grade 85%) is made by various methods: steam distillation under high vacuum, solvent extraction etc.

Lactic acid products (Dairy products): COMMERCIAL STARTER CULTURE PREPARATIONS A. Frozen Concentrated Cultures B. Freeze-Dried Cultures C. Spray-Dried Cultures

Starter culture problems 1. BACTERIOPHAGES Bacteriophages (phages) are viruses that infect bacteria. Bacteriophagic infection of starter cultures can result in failure of the fermentation and loss of product. The control process included the use of lactic acid bacteria genetically bacteriophagic resistance. engineered for

2. CULTURE INHIBITORS A. Raw Milk Associated Inhibitors Lactic starter cultures grow more slowly in raw than in heated milk; caused by the presence of natural lactoperoxidase system significant microbial inhibitor in raw milk.Other naturally microbial inhibitors in milk include lysozyme and lactoferrin. inhibitors. is The most the

B. Antibiotics Treatment application of antibiotics. Milk from treated cows cannot be legally sold. The resulting contamination may be inhibit starter culture microorganisms. of mastitis in cows involves low-level antibiotic

C. Chemical Sanitizers Chemical sanitizers may contaminate milk, usually as a result of human error. Chlorine- and iodine-based sanitizers lose their activity in milk and are, therefore, unlikely to cause starter culture inhibition. Quaternary ammonium compounds present more potential problems, maintain activity in milk, and lactic acid bacteria are sensitive to low concentrations because they

Probiotics and health aspects Probiotics microorganisms which when administered in adequate amount confer a health benefit to the host".(like Bifidobacterium, Streptococcus) . The prebiotic as a non-digestible food ingredient that beneficially affects the host by selectively stimulating the growth and/or activity of one or a limited number of bacteria in the colon . A synbiotic is a synergistic combination of a probiotic and prebiotic. have been defined as "Live Lactobacillus, or

Yoghurt Yogurt (yoghurt) is a fermented dairy product, manufactured from pasteurized milk. Its fat content ranges from 0 to over 4% . Roles of Starter Cultures in yogurt a. Acidification: Yogurt is made using a combination of S. thermophilus and Lb. delbrueckii subsp. bulgaricus. These organisms grow in a cooperative relationship resulting in rapid acidification. The presence of lactobacilli stimulates growth of the more weakly proteolytic S. thermophilus, because lactobacilli liberate free amino acids and peptides from casein . S.thermophilus, in turn, stimulates growth of Lb. delbrueckii subsp. bulgaricus; by removing oxygen, lowering pH, and producing formic acid and pyruvate.

Yogurt may also contain Lb. acidophilus or other (probiotic cultures), this type of yogurt called probiotic yogurt.

The most important characteristics for yogurt cultures are: (1) rapid acidification, (2) production of characteristic balanced flavor (3) ability to produce the desired texture. Acidification refrigeration, but the culture may continue to acidify slowly at cold temperatures. of yogurt is controlled by

b. Flavor: The yogurt flavor is a balanced blend of acidity and acetaldehyde. This is achieved through balance of rod to coccus ratio, and fermentation control. c. Texture: The texture of yogurt results from a complex interaction between milk proteins, acid, and exocellular polysaccharide produced by the starter culture . Several different types of yogurt are commercially available. These include plain (no added flavors), flavored, liquid, carbonated, and low lactose.

Manufacture of yogurt: Manufacture of yogurt steps: * Standardization of mix(Standardization of fat and solid content in milk), *Homogenization at 50-55c or 65c, * Heat treatment( pasteurization), *Cooling to incubation temperature, *Inoculation with yogurt cultures S. thermophilus and Lb. delbrueckii subsp. bulgaricus., *Incubation(45c for 4-6 h), *Cooling to 2-4 c, and Packaging.