John Deere G100 and G110 Garden Tractor Service Repair Manual Instant Download (tm2020)

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

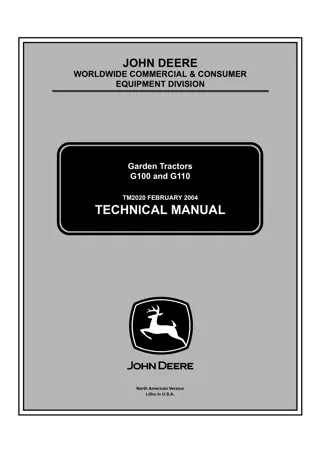

JOHN DEERE WORLDWIDE COMMERCIAL & CONSUMER EQUIPMENT DIVISION Garden Tractors G100 and G110 TM2020 FEBRUARY 2004 TECHNICAL MANUAL North American Version Litho in U.S.A.

INTRODUCTION Manual Description Safety Specifications and Information Engine (Kohler) Electrical Power Train Steering Attachments NOTE: Depending on the particular section or system being covered, not all of the above groups may be used. Miscellaneous w w

SAFETY Handle Fluids Safely - Avoid Fires Recognize Safety Information Be Prepared For Emergencies Understand Signal Words Replace Safety Signs Use Care In Handling And Servicing Batteries

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

SAFETY Prevent Battery Explosions Use Care Around High-pressure Fluid Lines p p Avoid High-Pressure Fluids Prevent Acid Burns Avoid acid burns by: If you spill acid on yourself: If acid is swallowed: Avoid Heating Near Pressurized Fluid Lines Wear Protective Clothing

SAFETY Parking Safely Support Machine Properly and Use Proper Lifting Equipment Service Machines Safely Using High Pressure Washers Use Proper Tools Illuminate Work Area Safely DO NOT Work In Ventilated Area Work In Clean Area Before starting a job:

SAFETY Service Tires Safely Warning: California Proposition 65 Warning Remove Paint Before Welding or Heating Avoid Harmful Asbestos Dust Avoid Injury From Rotating Blades, Augers And PTO Shafts

SAFETY Service Cooling System Safely Live With Safety Handle Chemical Products Safely Dispose of Waste Properly

SPECIFICATIONS & INFORMATION TABLE OF CONTENTS Table of Contents Fastener Torques..............................................9 General Information........................................11 Serial Number Locations ...............................15

SPECIFICATIONS & INFORMATION FASTENER TORQUES Fastener Torques Metric Fastener Torque Values 12.9 4.8 8.8 9.8 10.9 Property Class and Head Markings 12.9 10.9 8.8 9.8 4.8 8.8 9.8 12.9 4.8 10.9 12.9 Property Class and Nut Markings 12 10 10 5 10 10 12 5 5 10 10 12 o Lubricated means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. Dry means plain or zinc plated (yellow dichromate - Specification JDS117) without any lubrication

SPECIFICATIONS & INFORMATION FASTENER TORQUES Inch Fastener Torque Values 8 5 5.1 5.2 8.2 1 or 2b SAE Grade and Head Markings No Marks 5 2 SAE Grade and Nut Markings 8 No Marks o Lubricated means coated with a lubricant such as engine oil, or fasteners with phosphate and oil coatings. Dry means plain or zinc plated (yellow dichromate - Specification JDS117) without any lubrication Grade 2 applies for hex cap screws (Not Hex Bolts) up to 152 mm (6 in.) long. Grade 1 applies for hex cap screws over 152 mm (6 in.) long, and for all other types of bolts and screws of any length.

SPECIFICATIONS & INFORMATION GENERAL INFORMATION General Information Gasoline CAUTION: Avoid Injury! Gasoline is HIGHLY FLAMMABLE, handle it with care. DO NOT refuel machine while: Indoors, always fill gas tank outdoors; Machine is near an open flame or sparks; Engine is running, STOP engine; IMPORTANT: Avoid damage! California Proposition 65 Warning: Gasoline engine exhaust from this product contains chemicals known to the State of California to cause cancer, birth defects, or other reproductive harm. first; Engine is hot, allow it to cool sufficiently smoking. Help prevent fires: Fill gas tank to bottom of filler neck only; Gasoline Storage Be sure fill cap is tight after fueling; Clean up any gas spills IMMEDIATELY; IMPORTANT: Avoid damage! Keep all dirt, scale, water or other foreign material out of gasoline. of excess grease, oil, debris, and faulty or damaged parts. Keep machine clean and in good repair - free John Deere Gasoline Conditioner and Stabilizer (TY15977) Any storage of machines with gas left in tank should be in an area that is well ventilated to prevent possible igniting of fumes by an open flame or spark, this includes any appliance with a pilot light. To prevent fire or explosion caused by STATIC ELECTRIC DISCHARGE during fueling: POLYETHYLENE PLASTIC fuel container and funnel WITHOUT any metal screen or filter. ONLY use a clean, approved To avoid engine damage: ONLY use clean, fresh unleaded gasoline with an octane rating (anti-knock index) of 87 or higher

SPECIFICATIONS & INFORMATION GENERAL INFORMATION Engine Oil Engine Break-In Oil IMPORTANT: Avoid damage! ONLY use a quality break-in oil in rebuilt or remanufactured engines for the first 5 hours (maximum) of operation. DO NOT use oils with heavier viscosity weights than SAE 5W- 30 or oils meeting specifications API SG or SH, these oils will not allow rebuilt or remanufactured engines to break-in properly. TURF - GARD - SAE 10W-30; PLUS - 4 - SAE 10W-30; also recommended TORQ - GARD SUPREME - SAE 5W-30 PLUS - 4 - SAE 10W-40 TORQ - GARD SUPREME - SAE 30. BREAK-IN ENGINE OIL also recommended as a break-in engine oil TORQ - GARD SUPREME - SAE 5W-30. SAE 30 SAE 10W-40 SAE 10W-30 IMPORTANT: Avoid damage! After the break-in period, use the John Deere oil that is recommended for this engine. SAE 5W-30 PREFERRED AIR TEMPERATURE

SPECIFICATIONS & INFORMATION GENERAL INFORMATION BREAK-IN OIL SAE 5W-30 SAE 10W-30 SAE 5W-30 PREFERRED AIR TEMPERATURE John Deere Dealers: AIR TEMPERATURE John Deere Dealers: Hydrostatic Transmission Oil Synthetic Lubricants IMPORTANT: Avoid damage! ONLY use a quality SAE 5W-50 SYNTHETIC engine oil in this transmission. Mixing of two viscosity grade oils is NOT RECOMMENDED. DO NOT use BIO-HY-GARD in this transmission. r

SPECIFICATIONS & INFORMATION GENERAL INFORMATION Chassis Grease Alternative Lubricants IMPORTANT: Avoid damage! ONLY use a quality grease in this application. DO NOT mix any other greases in this application. DO NOT use any BIO- GREASE in this application. IMPORTANT: Avoid damage! Use of alternative lubricants could cause reduced life of the component. HIGH-TEMPERATURE EP GREASE - JDM J13E4, NLGI Grade 2. GREASE-GARD - JDM J13E4, NLGI Grade 2. Lubricant Storage Mixing of Lubricants NLGI Grade 2 JDM J13E4 Oil Filters IMPORTANT: Avoid damage! Filtration of oils is critical to proper lubrication performance. Always change filters regularly. AIR TEMPERATURE John Deere Dealers:

SPECIFICATIONS & INFORMATION SERIAL NUMBER LOCATIONS Serial Number Locations Engine Identification Number Product Identification Number (PIN) A B A Hydrostatic Transaxle Identification Number A Note: G100 Shown

ENGINE - GAS TABLE OF CONTENTS Table of Contents Specifications .................................................19 Diagnostics .....................................................26 Theory of Operation .......................................27 Tests and Adjustments..................................29 Repair...............................................................39

ENGINE - GAS SPECIFICATIONS Specifications General Specifications G100 Engine: Make. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kohler Model Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . CV23S-75569 Horsepower. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17.2 kW (23 hp) Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 674 cc (41.1 cu in.) Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80.0 mm (3.15 in.) Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 mm (2.64 in.) G110 Engine: Make. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Kohler Model Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .CV730-0040 Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18.6 kW (25 hp) Displacement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 725 cc (44.0 cu in.) Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 83.0 mm (3.27 in.) Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 67 mm (2.64 in.) All Engines: Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 Stroke/Cycle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 Valves . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Overhead Valves Compression Ratio - G100. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8.5:1 Compression Ratio - G110. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9.0:1 Compression Release . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Automatic/Centrifugal Crankshaft Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Vertical Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Fully Pressurized 0 - 413 kPa (0 - 60 psi) Oil Filter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Single Element, Full Flow, Spin-On Filter Crankcase Oil Capacity - G100: w/o Oil Filter). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.8 L (1.9 qt) w/ Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 L (2.0 qt) Crankcase Oil Capacity - G110: w/o Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.9 L (2.0 qt) w/ Oil Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.0 L (2.1 qt) Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Air Cooled Air Cleaner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Dual Stage Muffler . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Horizontal Discharge Below Frame Fuel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 L (2.1 gal) Fuel Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Replaceable (In-Line Type) Fuel Shut-Off Solenoid. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Replaceable (Below Carburetor Float Bowl) Spark Plug-Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Champion RC12YC or Equivalent

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

ENGINE - GAS SPECIFICATIONS Tests and Adjustments Specifications Valve Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . None (Hydraulic Lifters) Automatic Compression Release Minimum Lift (Engine Cold) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.25 mm (0.01 in.) Oil Pressure (Minimum at 1250 rpm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124 kPa (18 psi) Crankcase Vacuum (Minimum At Operating Temp.) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15 cm (6.0 in.) Ignition Module Air Gap. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.20 - 0.30 mm (0.008 - 0.0012 in.) Maximum Compression Pressure Variation Between Cylinders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 138 kPa (20 psi) Cylinder Compression Pressure (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1125 kPa (160 psi) Oil Pressure Sensor Activates . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21 - 35 kPa (3 - 5 psi) Carburetor Slow Idle Mixture Screw Initial Setting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Lightly Seat, Then 1 Turn Out Fuel Pressure (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 kPa (0.3 psi) Fuel Flow (minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.5 L/hr (2 gph) Slow Idle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1700 75 rpm Fast Idle Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3350 75 rpm Spark Plug-Gap . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.76 mm (0.030 in.) Repair Specifications Cylinder Head: Cylinder Head Flatness (Maximum Warp) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.08 mm (0.003 in.) Push Rod: Maximum Bend. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.76 mm (0.030 in.) Valves and Valve Lifters: Hydraulic Lifter to Crankcase Running Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.02 - 0.05 mm (0.001 - 0.002 in.) Intake Valve-to-Guide Clearance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.04 - 0.08 mm (0.002 - 0.003 in.) Intake Valve Stem OD. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.98 - 7.00 mm (0.275 - 0.276 in.) Oversize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.23 - 7.25 mm (0.284 - 0.285 in.) Intake Valve Guide ID: New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.04 - 7.06 mm (0.277 - 0.278 in.) Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.13 mm (0.281 in.) Oversize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.29 - 7.31 mm (0.287 - 0.288 in.) Exhaust Valve-to-Guide Clearance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.05 - 0.09 mm (0.002 - 0.004 in.) Exhaust Valve Stem OD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.97 - 6.99 mm (0.274 - 0.275 in.) Oversize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.22 - 7.24 mm (0.284 - 0.285 in.) Exhaust Valve Guide ID: New . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.04 - 7.06 mm (0.277 - 0.278 in.) Maximum. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.16 mm (0.282 in.) Oversize. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.24 - 7.31 mm (0.285 - 0.288 in.) Valve Guide Reamer: Standard . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.05 mm (0.278 in.) Oversize (0.25 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.30 mm (0.287 in.) Intake Valve Lift (Minimum - Engine Cold) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.07 mm (0.318 in.) Exhaust Valve Lift (Minimum - Engine Cold) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8.07 mm (0.318 in.) Valve Face Angle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45 Valve Seat Angle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44.5 Valve Margin (Minimum) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1.50 mm (0.06 in.)

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com