_Innovative Approaches to Formulating Probiotic Products

From prebiotic-rich formulations to the emerging realm of postbiotics, our blog navigates the cutting edge of nutritional science. nnMore info >> // /blog/new-product-development/innovative-approaches-probiotic-formulation/ nnContact Us nnUK- 44 161 394 1144 nnIndia - 91 9566299022 nnMail Id: info@foodresearchlab.com

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

INNOVATIVE APPROACHES TO FORMULATING PROBIOTIC PRODUCTS INNOVATIVE APPROACHES TO FORMULATING PROBIOTIC PRODUCTS A presentation by Dr. Nancy Agnes, Head, Technical Operations, FoodResearchLab Group: www.foodresearchlab.com Email: info@foodresearchlab.com

What is Gut Flora? The symbiotic flora in the human gut is more numerous and complex than that found in other areas of the body. In the colon, there are roughly 3.9 1013 adult intestinal flora, which is marginally greater than the total number of human cells. Intestinal flora can be categorized into three functional groups based on their effect on human health: probiotics, neutral bacteria, and pathogenic bacteria. The human body and intestinal flora interact to generate functional molecules including amino acids, vitamins, short- chain fatty acids, metabolise toxic waste, and aid in absorption of nutrients from food.

Current Trends in Probiotic Formulation Novel advancements in the composition of dried probiotics encompass application, like nasal sprays and creams or lotions. alternative modes of Probiotic formulations are advantageous for the upper respiratory tract (URT), helping to prevent acute respiratory tract infections. The formulation and maximum shelf-life stability: 4.5% (w/v) lactose and 1% (w/v) HPMC; 2.5% (w/v) trehalose and 1% (w/v) methylcellulose); 2.5% (w/v) sucrose and 0.4% (w/v) xanthan gum; 2.5% (w/v) isomalt and 0.4% (w/v) xanthan gum following formulation exhibited a stable HPMC (hydroxypropyl

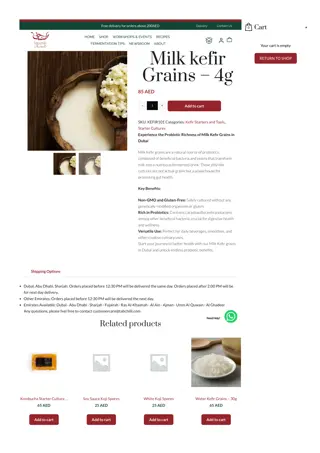

Applications in Dairy Industry Dairy products with probiotics are manufactured and consumed globally in a variety of forms, including pasteurized milk, fermented milk, and ice creams. new-born formula, Certain foods, such as cheese and fermented milk, are more suited as probiotic carriers because of their ability to buffer pH and fat content, which gives probiotics more protection as they go through the GI system. Probiotics, prebiotics, conjugated linoleic acids, sterols, stanols, reduced lactose or lactose-free yogurts, and yogurts enriched with functional ingredients have all enjoyed long-term market success.

Applications in Beverage Industry Fruit juices enhanced with probiotics occupies a distinctive place in the food and beverage market. Due to the unfavourable conditions that probiotics in beverages endure, their viability in non-dairy foods is shorter than that of dietary supplements. Probiotic juice manufacturing involves a number of considerations for processors, temperature, anthocyanin, vegetative form of the bacteria. including pH, and above all a

Applications in Bakery Industry A variety of important nutritional components, including carbohydrates, proteins, lipids, dietary fiber, vitamins, and minerals, are included in varied levels in bakery items (bread, biscuits, doughnuts, cookies, etc.). In an effort to provide probiotics the ability to withstand the high temperatures involved in baking, researchers have been working to develop novel delivery methods for thermo-durable bioactive materials. Examples include: Leveraging microencapsulation and sourdough method for bread making and encapsulation of L. rhamnosus in sodium alginate for pan bread baking

CONTACT US UNITED KINGDOM +44- 161 394 1144 INDIA +91 9566299022 EMAIL info@foodresearchlab.com