Improving Performance of Compressed Earth Blocks Through Pozzolanic Reaction

Enhancing the strength and durability of compressed earth blocks for modern construction using chemical stabilization methods involving materials like calcium carbide residue and rice husk ash. Experimental approaches and raw material processing are detailed in the study, focusing on binder additions and their impact on the earthen material. The research explores various ratios and combinations of binders to optimize the performance of compressed earth blocks in both saturated and dry conditions.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Amlioration des performances des briques en terre comprim es travers une r action pouzzolanique NSHIMIYIMANA Philbert, MESSAN Adamah, COURARD Luc SustainEng2018: 12-14/12/2018, Ouagadougou-Burkina Faso

Compressed earth blocks for construction of modern housing 2

Compressed earth blocks for construction of modern housing Modern compressed earth blocks (CEBs) (~2 MPa) Traditional adobe bricks (~1 MPa) 3 Houben and Guillaud, 2006; Bogas et al. 2018

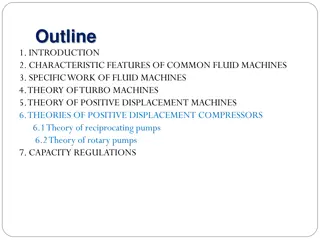

Chemical stabilization improves the performances of CEBs in saturated and dry conditions 1. Cement: hydration reaction requires ~28 days of curing. 2. Lime: pozzolanic reaction requiring >28 days of curing. 3. Geopolymer: geopolymerization of aluminosilicates by activation with alkaline solutions. 4 Houben & Guillaud, 2006; Bogas et al. 2018; Al-Mukhtar et al. 2010, 2014; Sore et al. 2018

Calcium carbide residue (CCR) and rice husk ash (RHA) for improving the performances of CEBs 1. Kinetic of reaction in solutions of mixtures : Earth + CCR (calcium carbide residue) Earth + CCR:RHA (rice husk ash) 2. Mechanical performances: CEBs stabilized with CCR CEBs stabilized with CCR:RHA 3. Mineral changes in cured mixtures. 5

EXPERIMENTAL APPROACH 6

Raw materials were processed and characterized Earthen material Pulverized (<5 mm) Kaolinite (>75 %) CCR Ball milled (<125 m) Active lime (~ 50 %) RHA Calcinated : 500 C (2 h) Ball milled (<80 m) Amorphous silica (70 %) 7

Binder (CCR/CCR:RHA) was added to the earthen material on weight percentage basis 0 - 5 - 8 - 10 10 (9:1) (8:2) (7:3) (6:4) 15 15 20 20 25 25 CCR CCR: RHA (13.5:1.5) (12:3) (10.5:4.5) (9:6) (18:2) (16:4) (14:6) (12:8) (22.5:2.5) (20:5) (17.5:7.5) (15:10) (ratios) 8

Mix solutions and CEBs were prepared, cured and characterized Concentration of free calcium [Ca2+] Compressive strength in saturated and dry condition Mineral change by XRD 2. Prodution and Curing stabilized CEBs (45 days), 40 2 C 1. Curing mix solutions (1-90 days); 40 2 C 9

RESULTS & IMPLICATIONS 10

Concentration of unconsumed calcium [Ca2+] in mix solutions reached the minimum after 45 days Earth+20 % CCR Earth+20 % CCR:RHA(16:4) 28 45 Consumption of free [Ca2+] during the pozzolanic reaction 11

CEBs stabilized with CCR/ CCR:RHA were resistant to the degradation after 2 hours in water Stabilized CEBs (5 % CCR) Unstabilized CEBs (0 % CCR) Pozzolanic reaction improved the cementation in CEBs 12

Compressive strength of CEBs was improved and reached the maximum with 10-20 % CCR Two-torey housing Dry Saturated Compressive strength required for load-bearing wall (4 MPa) 13

Compressive strength of CEBs was further improved with 20 % CCR:RHA in 16:4 ratio Three-storey housing Two-storey housing Dry Saturated RHA accelerated the pozzolanic reaction resulting in occurrence of extra compressive strength (6 MPa) 14

Cementitious products formed from the pozzolanic reaction between aluminosilicates and CCR CSH: Calcium Silicate Hydrate; CAH: Calcium Aluminate Hydrate K: kaolinite; P: Portlandite (active lime) 15

CONCLUSIONS & REMARKS 16

Conclusions and studies in perspective Hydro-mechanical performances of CEBs were improved by stabilization with by-products : 10-25 % CCR alone reaches 4 MPa required for two- storey housing; 20 % CCR:RHA (16:4) reaches 6 MPa for tree-storey housing; Investigate the performance of stabilized CEBs at early age; Investigate the durability of CCR/CCR:RHA stabilized CEBs 17

MERCI POUR VOTRE ATTENTION PRD 2016-2021: Am lioration de la qualit de l habitat en terre crue au Burkina Faso philbert.nshimiyimana@2ie-edu.org pnshimiyimana@doct.uliege.be Skype ID: philbert.nshimiyimana 18