Heat Transfer Film & In Mould Labels manufacturer in India

PB HOLOTECH INDIA. PVT. LTD. is the only manufacturer of Heat Transfer Film, Labels or foils in Eastern India for Plastic containers, utensils, writing instruments, buckets, cosmetics containers etc. We have specialised on PP, ABS, PET, PVC, GLASS, H

Uploaded on | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

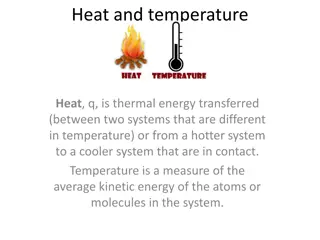

Heat Transfer Film & In Mould Labels manufacturer in India Why Top Brands Are Switching to Heat Transfer Film & In-Mould Labels The packaging industry has witnessed a major transformation with the rise of Heat Transfer Film & In-Mould Labels (IML). These advanced labeling techniques are helping brands enhance their product appeal while improving durability and sustainability. As a result, top brands across various industries are making the switch. But why? Let s explore. What Are Heat Transfer Film & In-Mould Labels? Heat Transfer Film (HTF) Heat Transfer Film is a specialized decorative film that uses heat and pressure to apply graphics onto a product surface. It is widely used in plastics, textiles, and metal surfaces to create vibrant, long-lasting designs.

In-Mould Labels (IML) IML is an advanced labeling technology where pre-printed polypropylene (PP) labels are placed inside a mold before injecting molten plastic. This process fuses the label with the product itself, resulting in a highly durable and aesthetically appealing design. The Key Benefits of Heat Transfer Film Superior Durability Resistant to scratches, water, and environmental conditions High-Quality Finish Delivers sharp, vibrant designs Cost-Effective Reduces production costs by eliminating additional label application steps Eco-Friendly Uses fewer adhesives and chemicals Versatile Applications Suitable for plastic, metal, and glass surfaces Advantages of In-Mould Labels (IML) Long-Lasting Since the label integrates with the plastic, it won t peel or fade Enhanced Aesthetic Appeal Achieves a seamless look with photo-realistic graphics Eco-Friendly Uses recyclable polypropylene, reducing plastic waste Efficient Production Reduces extra label application steps, improving productivity Why Are Top Brands Switching to These Solutions? Many global brands are adopting Heat Transfer Film & In-Mould Labels due to their durability, cost savings, and environmental benefits. Here are some real-world applications: Coca-Cola & Pepsi: Using IML for long-lasting, high-quality bottle branding Unilever & P&G: Enhancing packaging for homecare and beauty products Automobile Industry: Using HTF for durable branding on car interiors and exteriors

Applications of Heat Transfer Film & IML Packaging Industry: Used in food, beverage, and cosmetic containers Automobile Industry: Branding on dashboards, trims, and accessories Home Appliances: Durable labeling on washing machines, air conditioners, and more Consumer Goods: Toys, electronics, and promotional products Comparison: Heat Transfer Film vs Traditional Labels Feature Heat Transfer Film Traditional Labels Durability High Moderate Cost Cost-effective in large-scale production Higher costs over time Aesthetic Appeal Seamless, premium finish May peel or fade over time Eco-Friendliness Less adhesive, recyclable Uses more plastic-based adhesives Manufacturing Process of Heat Transfer Film Design & Printing: Graphics are printed onto the transfer film Coating Application: Adhesive and protective coatings are added Heat Transfer Process: The film is pressed onto the product using heat & pressure Peeling & Finishing: The film is removed, leaving a high-quality print How In-Mould Labels Are Produced Label Placement: A pre-printed label is positioned inside an injection mold Plastic Injection: Molten plastic is injected, fusing the label with the product Cooling & Ejection: The molded product is cooled and removed

Market Trends & Future of Heat Transfer Film & IML The market for Heat Transfer Film & IML is expected to grow rapidly due to increasing demand for sustainable, cost-effective labeling solutions. Future trends include: Biodegradable Labels Innovations in eco-friendly materials Smart Labels Integration with RFID & NFC technology Enhanced Customization AI-powered design tools for personalized branding FAQs 1. Are Heat Transfer Films waterproof? Yes, they are resistant to water, UV rays, and scratches. 2. Can In-Mould Labels be customized? Absolutely! Brands can choose from various colors, textures, and finishes. 3. Are these labeling solutions eco-friendly? Yes, IML is fully recyclable, and HTF uses fewer adhesives. 4. What industries use Heat Transfer Film & IML? From packaging and automotive to home appliances and consumer goods. 5. Is Heat Transfer Film cost-effective? Yes, especially for large-scale production, as it eliminates extra label application steps. 6. How do I choose a reliable manufacturer? Look for quality certifications, customization options, and strong industry experience.

The shift towards Heat Transfer Film & In-Mould Labels is a game-changer for brands looking for cost-effective, durable, and sustainable packaging solutions. If you want to stay ahead in the competitive market, investing in these advanced labeling technologies is the way forward. PB Holotech India is a top-tier Heat Transfer Film & In-Mould Labels manufacturer in India, providing premium-quality labeling solutions for diverse industries. With cutting-edge technology and advanced printing techniques, PB Holotech ensures durable, vibrant, and eco-friendly labels for packaging, automotive, and consumer goods. Their customized solutions enhance product branding, offering high-definition prints with superior adhesion. Known for innovation, reliability, and cost-effectiveness, PB Holotech is a trusted name for businesses seeking long-lasting, aesthetic, and sustainable labeling options. Partner with PB Holotech India for high-performance Heat Transfer Film & In-Mould Labels that elevate your brand's packaging appeal. For Enquiry PB HOLOTECH INDIA. PVT. LTD. CB-70, Saltlake City, Kolkata: 700064 Telephone: + 91-33-23580400 Mobile: + 91-9830189898 E-mail: info@labelholograms.com, sales@labelholograms.com Visit: https://www.labelholograms.com/