Guidelines for Maintaining Hygiene in Manufacturing Environments

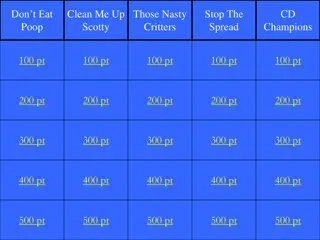

The article highlights the importance of hygiene in both manufacturing industries and hospitals, covering key aspects such as manufacturing processes, quality assurance, good manufacturing practices, quality control, and microbial contamination control. Environmental cleanliness and hygiene play a crucial role in minimizing contamination risks, emphasizing the need for proper control measures at various stages of production.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

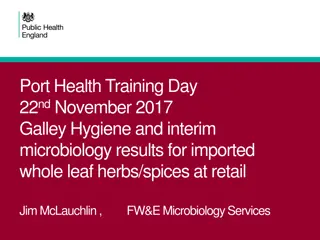

FACTORY AND HOSPITAL HYGIENE Prof. Dr. Shumaila Bashir

INTRODUCTION Manufacturing is carried out in both industuires and hospitals In the latter, batches tend to be much smaller sometimes only one item and the products are stored for much less time usually less than 24 hours

MANUFACTURE Manufacture is the complete cycle of production of a medical product

QUALITY ASSUARANCE (QA) Sum total of the arrangements made to ensure that the final product is of a quality required for its intended purpose

GOOD MANUFACTURING PRACTICES Part of the quality assuarance that is aimed at ensuring that the product is consistently manufactured to a quality appropriate for its intended use

QUALITY CONTROL(QC) Part of GMP that ensures that necessary test are conducted and product is not released until it has passed these tests

IN-PROCESS CONTROL Any test on a product , the environment or the equipment that Is made during the manufacturing process

CONTROL OF MICROBIAL CONTAMINATION DURING MANUFACTURE

GENERAL ASPECTS A pharmaceutical product may become contaminated by a number of means and at several points during manufacture There are sebveral ways in which this risk can be minimized

ENVIRONMENTAL CLEANLINESS AND HYGIENE Transfer of microbes to a product from working surfaces,fixtures, equipment and pooled stagnant water fall out of dust , droplet borne microbes from atmosphere Personel who are are working in the area

QUALITY OF STARTING MATERIALS Raw materials including water supplies Storage conditions must be appropriate Treated water must be used

PROCESS DESIGN The manufacturing process must be Fully defined Facilities available Product microbiologically acceptable According to specifications

QUALITY CONTROL AND DOCUMENTATION Quality control tests must be performed Documentation include: 1. Details of starting materials 2. Packaging material 3. Distribution record

PACKAGING,STORAGE AND TRANSPORT PRIMARY PACKAGING: it keeps the contents in SECONDARY PACKAGING: for storage and transport

MANUFACTURE OF STERILE PRODUCTS

REQUIREMENT Strict aseptic techniques are required for the manufacturing of sterile products

CLEAN AND ASEPTIC AREAS DESIGN OF PREMISES: sterile production should be carried out in a separate manufacturing area INTERNAL SURFACES,FITTINGS AND FLOORS: 1. avoid microbial contamination from all working surfaces 2. Internal fittings such as cupboards drawers and shelves should be kept to a minimum

SERVICES: lightening services Electrical Switches Sinks and drains AIR SUPPLY: Filtered Air is used to achieve the necessary standards CLOTHING: Must be of non shedding fibre CHANGING FACILTIES: Entry to an aseptic area should be through a changing room fitted with interlocking room

CLEANING AND DISINFECTION: A strict disinfection policy is necessary by using cleaning agents including: 1. Alkaline detergents 2. Non ionic surfactants 3. Clear soluble phenolics

undefined

undefined