Garments Dyeing Process in Textile Industry

Garments dyeing is a method of coloring garments to achieve the desired shade, involving processes like over-dyeing, dip dyeing, tie dyeing, and tinting. This technique is gaining popularity for various garments like jeans, shirts, socks, and more due to advantages such as lower production costs, shorter turnaround times, and the ability to work with small lots efficiently. However, precautions must be taken in garment design, fabric selection, and thread quality to ensure uniform dyeing results.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

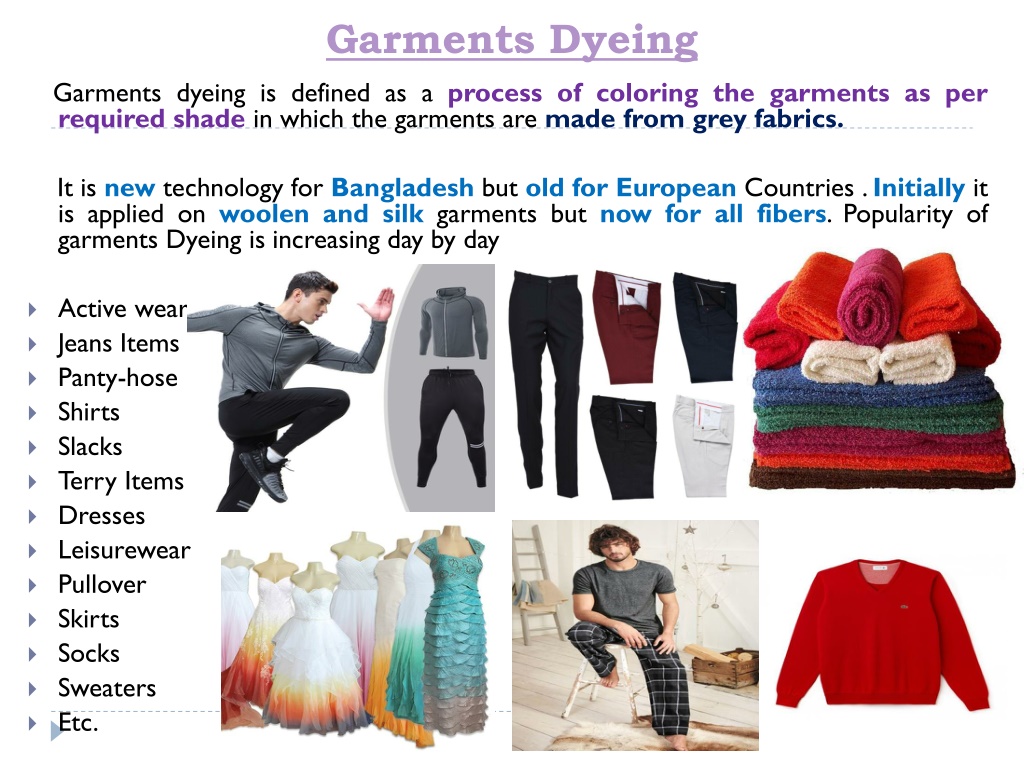

Garments Dyeing Garments dyeing is defined as a process of coloring the garments as per required shade in which the garments are made from grey fabrics. It is new technology for Bangladesh but old for European Countries .Initially it is applied on woolen and silk garments but now for all fibers. Popularity of garments Dyeing is increasing day by day Active wear Jeans Items Panty-hose Shirts Slacks Terry Items Dresses Leisurewear Pullover Skirts Socks Sweaters Etc.

All are done by same process????? http://4.bp.blogspot.com/-KudctD-W-3Y/UrBhy-rh5OI/AAAAAAAAANw/2edIx7zxtAo/s320/3d_101309.jpg http://1.bp.blogspot.com/-uAlJaj4UUQM/UrBhybWiytI/AAAAAAAAANo/ooXQf8fz4kg/s1600/Dip_Dyeing_Textileaid+%281%29.JPG http://2.bp.blogspot.com/-1qlJqLf3R88/UrBhyxkxXvI/AAAAAAAAANs/PGcDoOY7YIk/s320/Tie_dye_Textileaid.blogspot.com.jpg http://1.bp.blogspot.com/-mjzlyWXHy60/UrBh1W9PpbI/AAAAAAAAAOA/hhfxK8XNpS4/s320/Tinting_textileaid.blogspot.com.png

Types of Garments Dyeing Over Dyeing: Done over any dyed and white garments. Garments of100% cotton can be only over dyed. Dip Dyeing: In a dyeing bath of direct or reactive dye garments to be dipped to a certain area as per requirements.Then subsequent after-treatments required. Tie Dyeing: Consists of folding, twisting, pleating, or crumpling a garment and binding with string or rubber bands,followed by application of dyestuffs. Tinting: After completing basic washing, some tint is added to the dye bath before softening to make it somewhat bluer, yellower, greener, redder or any color to match.

Advantages in GD Lower cost of production for any color and shade. Less time is required to produce and supply garments to the customers. Small lots can be made within short time. Pre-treatments like de-sizing, scouring, bleaching, dyeing and finishing could be done in the same machine. Lower liquor ratio with minimum energy consumption for dyeing. Old garments can be recycled and be converted to new garments. Lower capital investment cost to set-up a garments dyeing project. Lower wastage cost in garments dyeing.

Pre-cautions in GD Garments design:engineering point of view. Fabric Source:Same lot and source. Seams:not be too tight or too loose to avoid irregular dyeing. Mix Fabric (woven and knitted): Because of unequal shrinkage % seam pucker can occur. Mixed fibers:proper dye selection to avoid irregular dyeing. Poor quality metal: may be damaged during dyeing for salt and alkali. (better:nickel or its alloy) Sewing thread: same fibre like the garment fabric, to avoid color difference.

Continued Button: Button of casin, cellulose, nylon can be damaged but synthetic buttons are safe. Elastic: Natural or polyurethane may damage in bleaching. Copper free natural/polyurethane or polyester type elastic is safe. Interlining: Use recommended interlining Compactly cotton woven fabric: Use hot brand reactive dyes to avoid irregular dyeing Specific shade: Use specific dye Proper Pre-treatments:Needed to remove impurities. Crease marks:special chemicals may be needed

Selection of Interlining in GD During interlining otherwise it may be destroyed for chemicals & temperature. Interlining for the garments to be dyed should have the following properties: garments dyeing we should be careful to select Interlining should take-up equal amount of dyes and chemicals as the garment fabrics take-up. Bond strength between interlining and garment fabric should be unaffected. Handle property of the interlining attached areas of the garments should be as per requirements. Resin containing interlining may pick-up dye molecules, hence color variation problem between interlining areas and remaining areas of the garment will arise.