Fracture Mechanics in Materials Engineering

Fracture in materials is the separation of a body into two or more pieces under static stress. Fracture mechanics studies how materials fracture and their resistance to it, focusing on crack propagation. Historical instances like ship and bridge failures illustrate the catastrophic effects of fractures in various structures. Different fracture modes such as tensile and shear are explored, alongside the influential work of Griffith in understanding the energy dynamics of cracked materials.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

Simple fracture is the separation of a body into two or more pieces in response to an imposed stress that is static (i.e., constant or slowly changing with time) and at temperatures that are low relative to the melting temperature of the material. The applied stress may be tensile, compressive, shear, or torsional.

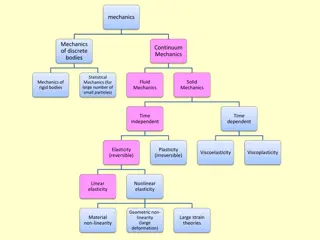

The study of how materials fracture is known as fracture mechanics and the resistance of a material to fracture is known as its toughness . The theory of fracture mechanics assumes the pre-existence of cracks and develops criteria for the catastrophic growth of these cracks.

Out of 2500 liberty ships built in world war II, 145 ships broke in two. Steam turbines 1950. Framed welded tankers 1954. Comet aircraft 1955. King bridge in Melbourne 1962. Pleasant bridge in Virginia 1967. Tank Barge vessel 1972

An oil tanker that fractured in a brittle manner by crack propagation around its girth. (Photography by Neal Boenzi. Reprinted with permission from The New York Times.)

A natural gas pipeline that failed during field testing. From E. Parker, Brittle Fracture of Engineering Structures, Wiley, 1957, p. 269.

A ship that fractured while in port From C. F. Tipper, The Brittle Fracture Story, Cambridge Univ. Press, 1963.

I- Opening mode in tensile. II- In plane shear mode. III-Anti plane shear mode.

Photoelastic fringe pattern associated with a particular crack geometry.

Griffith noted in 1921 that when a stressed plate of an elastic material containing a crack, the potential energy decreased and the surface energy increased.

The total potential energy of the system is given by ? = ?? ??+ ?? ? = ?? ???2?2? ? + 2 2???? ? = Potential energy of the cracked body. ??= Potential energy of uncracked body. ??= Elastic energy due to the presence of the crack. ??= Elastic-surface energy due to the formation of crack surfaces. a = One-half crack length. 2 2?? = Total surface crack area. ??= Specific surface energy. ?= 1 for plane stress and ? = 1 ?2for plane strain.

2?? =????2 ? rearranging it, we will get a significant expression in linear elastic fracture mechanics (LEFM) 2??? ? ? ?? = ??= ? ?? The parameter ??is called the stress intensity factor. KICis the fracture toughness. Fracture occurs when ?? ???

? 2??cos? 21 + sin? 2sin3? ???= 2 ? 2??cos? ? 2??sin? 21 sin? 2sin3? ???= 2 2cos? 2cos3? ???= 2

Through- thickness central crack. ??= ? ?? for infinite plate. 1 2 for plate of finite width ? ??tan?? ??= ? ?? ?

Single edge crack. ??= ?? ? ? ? ? ? ? ? ? ? ? ? ? ? = ?.?? ?.?? + ??.? ??.?? + ??.??

Double edge crack. ??= ?? ? 2 3 ? ? 8.48 ? ? ? ? ? = 1.99 + 0.76 + 27.36