Emissions Reduction Equivalency Evaluation: OGI vs. Method 21 Update

May 2019 update presents data comparison of Optical Gas Imaging (OGI) and Method 21 for LDAR programs, excluding Chemical Plant data. Results show the impact of including Refinery, Gas Plant, and Chemical Plant data versus only Refinery and Gas Plant data, revealing varying leak rate reductions. Charts highlight differences in aggregate leak rate reductions and projected future measurements, emphasizing the importance of connector monitoring.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

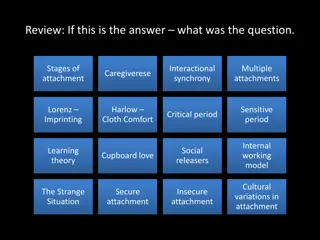

Summary for Transmittal to the U.S. EPA May 2019 Emissions Reduction Equivalency Evaluation: Comparison of Optical Gas Imaging to Method 21 for LDAR Programs Update showing charts that exclude Chemical Plant Data from the Comparison API OGI Working Group

Overview of Slides (1 of 2) Summary Comparison of Equivalency Data Refinery, Gas Plant, and Chemicals data all included Only Refinery and Gas Plant data included (excludes Chemical Plant data) OGI = Optical Gas Imaging; M21 = Method 21 Slides 4-7 show data with Refinery, Gas Plant and Chemical Plant data on the left chart and data for only Refineries and Gas Plants on the right chart Note that the y-axis scale differs on the two charts on each slide. Slide 4 Assumes no connectors are monitored currently at any facility Charts show that the aggregated leak rate reduction increases for scenarios that include Refinery, Gas Plant, and Chemical Plant data and that include only Refinery and Gas Plant data Slide 5 Prevailing connector monitoring requirements used as the data analysis basis for all sites; connector monitoring percentage and frequency vary depending upon local requirements (e.g., state rules, consent decree, etc.) Aggregate leak rate reduction is similar when Refinery, Gas Plant, and Chemical Plant data are included Larger aggregate leak rate reduction is shown when only Refinery and Gas Plant data are included 2

Overview of Slides (2 of 2) Slide 6 Charts show total component count, current total number of measurements, and the projected future number of measurements for: 1. Normal components, which include all equipment components that were not listed as Difficult-to- Monitor (DTM) or connectors. 2. DTMs 3. Connectors The ratio of the number of projected future number of measurements to the current total number of measurements is greater for the data set where only Refineries and Chemical Plants are considered Slide 7 Projected individual site changes in leak reduction rate under the assumptions used in Slide 4 Summation of individual site leak reduction rates should equal the totals shown on Slide 4 Slide 8 Projected individual site changes in leak reduction rate under the assumptions used in Slide 5 Summation of individual site leak reduction rates should equal the totals shown on Slide 5 Note that most individual Refineries and Gas Plants see an increased or similar leak reduction rate when including connectors in their monitoring program under OGI 3

Aggregate Leak Emissions Rate Data show an Increase in Leak Rate Reduction w/ and w/o Chemical Plant Data Included if No Connectors are Monitored Currently Refinery + Gas Plant + Chemical Plant Data Refinery + Gas Plant Data Only 4

Aggregate Leak Emissions Rate Data show an Increase in Leak Rate Reduction when only Refinery and Gas Plant Data are Considered at Current Facility-Specific Connector Monitoring Frequencies Refinery + Gas Plant + Chemical Plant Data Refinery + Gas Plant Data Only 5

Charts show the Total Number of Projected Future OGI Measurements Relative to the Total Number of Current Method 21 Measurements - Ratio of Future to Current Measurements is Higher for Refineries and Gas Plants Only Refinery + Gas Plant + Chemical Plant Data Refinery + Gas Plant Data Only 6

Individual Facility Leak Rate Reductions when Migrating from Method 21 to OGI, with an Assumption that No Connectors are Monitored Currently Refinery + Gas Plant + Chemical Plant Data Refinery + Gas Plant Data Only 7

Individual Facility Leak Rate Reductions when Migrating from Method 21 to OGI, with an Assumption that Connectors are Monitored Currently as per Facility-Specific Requirements -Most Refineries and Chemical Plants Show an Improved Leak Reduction Rate (Right Chart) Refinery + Gas Plant + Chemical Plant Data Refinery + Gas Plant Data Only 8

Data Analysis Assumptions Presented Originally on August 23, 2018

Data Analysis Assumptions 1 of 3 Leak rates estimated using Method 21 (M21) Screening Values (SVs) represent relative average VOC emissions Consequently, monitoring frequency of each component and time to repair are normalized Repairs are required for any component with a M21 SV 500 ppm Repairs are required for any component where OGI detects a leak Assumption: Optical Gas Imaging (OGI) detects leaks for M21 SVs 10,000 ppm After repairs are completed, the leak rate is negligible (i.e., zero) for calculation purposes Connectors are not monitored before the LDAR program shifts from M21 to OGI Data submitted by companies included monitoring at different frequencies: Initial monitoring of connectors only Annual subset (i.e., 10% of total connectors) Quarterly for all connectors (e.g., under Consent Decree requirement) All connectors are monitored quarterly in the future 11

Data Analysis Assumptions 2 of 3 DTM and connectors monitored on an annual basis can be converted to a quarterly monitoring basis by multiplying the number of DTMs or connectors by 4. The number of monitoring events for components monitored annually in current LDAR programs consequently increases by a factor of 4. Emissions reductions are calculated from facility-provided SVs Actual emissions for normal components, since they are monitored quarterly Actual emissions for connectors, where data were available Projected emissions using actual data from the survey for connectors Emissions rates for unmonitored connectors were assumed to have the same leak rate distribution as monitored connectors For sites with some monitored connectors, the site-specific component leak rate was applied For sites with no monitored connectors or limited connector data, average leak rates from sites with connector monitoring data were used to estimate future connector leak rates. This includes: Connectors that are only monitored initially (i.e., once) Connectors that are monitored infrequently (i.e., 10% or 200 connectors per year) 12

Data Analysis Assumptions 3 of 3 Leak rates calculated using M21 SVs and various SV correlations for different monitoring scenarios (scope & frequency) represent relative changes in emissions profiles upon implementing OGI and monitoring all connectors. Scenarios included: 1. M21 monitoring of normal components and DTMs only with SVs>500 Normal components quarterly DTMs annually 2. OGI monitoring of normal components and DTMs only with SVs>10,000 (OGI detection w/o connectors) Normal components quarterly DTMs annually 3. OGI monitoring of normal components, DTMs, and connectors with SVs>10,000 ppm (OGI detection on all connectors) Normal components quarterly DTMs quarterly (assumes all are OGI accessible) Connectors quarterly 13