Dust Control Products for Mining Operations: Enhancing Safety and Efficiency

Enhance mining safety and efficiency with advanced dust control products. Explore Dust Control Plus, soil stabilizers, water sprays, and foam solutions for effective dust management.n

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

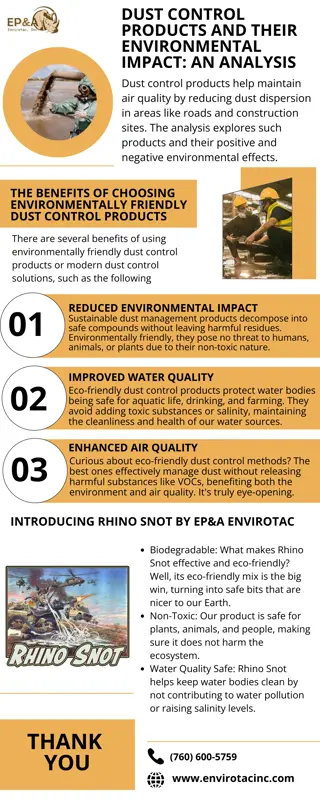

EP&A Envirotac,Inc. DUST CONTROL PRODUCTS FOR MINING OPERATIONS Enhancing Safety and Efficiency www.envirotacinc.com

IMPORTANCE OF DUST CONTROL IN MINING OPERATIONS Mining operations are crucial for the extraction of vital materials from the earth but come at a high cost, the biggest challenge being dust generation. Dust control is very necessary for mining operations because it has direct implications on both worker health and safety, operational efficiency, and the environment. Effective dust control products and solutions could significantly enhance operational safety and productivity for mining operations. At EP&A Envirotac Inc., we provide innovative dust control products designed for mining operations that deliver safe, productive environments.

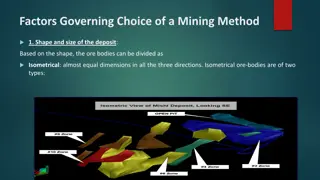

TYPES OF DUST CONTROL PRODUCTS FOR MINING There are various dust control products geared towards mining operations. All of these aim to address different problems in dust control. They include: Dust Soil Suppressants Stabilizers Chemical dust suppressants are applied to mining surfaces to prevent dust from becoming airborne by bonding dust particles and creating a crust. Products like Dust Control Plus offer long-lasting dust control, reducing the need for frequent applications and conserving water resources. This sort of product enhances the physical properties of soil, making the soil more erosion- and dust-resistant. In such a context, soil stabilizers will be quite helpful for the internal road construction work at the site since they would improve the durability and stability of haul roads, minimizing dust and maintenance costs in the transportation network.

Water Sprays Soil Stabilizers This sort of product enhances the physical properties of soil, making the soil more erosion- and dust-resistant. In such a context, soil stabilizers will be quite helpful for the internal road construction work at the site since they would improve the durability and stability of haul roads, minimizing dust and maintenance costs in the transportation network. This is one of the oldest methods of dust suppression. It involves frequent water spraying to suppress dust. As much as water spraying works to offer short-term dust control, it often requires frequent application and can be quite wasteful. To improve its efficiency, it is combined with other dust control products like chemical suppressants, hence offering a more sustainable dust control solution. Foam-Based Solutions Geotextiles and Mulching These are foam-based dust control products used in high dust-generation areas such as crushing and screening. The products create a foam barrier that traps dust particles, preventing them from becoming airborne. This foam-based solution has a quite effective capacity to lower dust emissions in areas of high activity significantly, ensuring a safer working environment for miners. Geotextiles are permeable fabrics that reinforce, protect, and stabilize soil surfaces. When laid on mining roads and other surfaces, geotextiles hold in the topsoil very effectively, preventing erosion and thereby exercising dust control. In mulching, organic or inorganic material is used to cover the top layer of soil, which helps reduce the generation of dust. These methods are usually used with dust control products to help hold or lock them in, hence enhancing their functions.

IMPLEMENTATION OF DUST CONTROL SOLUTIONS IN MINING OPERATIONS The implementation of effective dust control solutions within mining operations calls for a holistic approach to address correctly the dust control needs at the site: site assessment, product selection, application methods, and monitoring and maintenance. SITE ASSESSMENT PRODUCT SELECTION This starts with a proper assessment of the mining site to locate areas that are prone to the generation of high dust and thus may be potentially difficult to control. At this stage, the selection of the most appropriate dust control products and solutions for the site will be done. The selection of the proper dust control products for the mining operation must be based on the needs identified. The type of dust, site conditions, and regulatory requirements are major factors to consider when choosing dust control products.

Application Methods The application of the chosen dust control products through appropriate application methods ensures their effectiveness. It could be in the form of spraying, spreading, or even mixing with the soil. Proper application can derive full benefit from dust control solutions. Monitoring and Maintenance Periodic checking for the effectiveness of the dust control solutions and maintenance ensures that the dust control measures in place are effective and can be sustained over time.

BENEFITS OF EFFECTIVE DUST CONTROL IN MINING Effective dust control in mining operations offers benefits like improved visibility, reduced health risks, and safer working conditions. It also enhances equipment efficiency, reduces maintenance costs, safeguards the environment, ensures regulatory compliance, and leads to long-term cost savings.

CASE STUDIES: SUCCESSFUL DUST CONTROL IN MINING Mining operations use dust control solutions to improve safety and efficiency. Examples include using Dust Control Plus and soil stabilizers in an Australian coal mine to reduce dust emissions and enhance road stability. Another case involves a South African gold mine using foam-based solutions to trap dust particles during crushing and screening, improving air quality, visibility, worker safety, and operational efficiency.

Thank You For your attention (760) 600-5759 www.envirotacinc.com