Cutting-Edge Applications of Carbon Nanotubes

Carbon nanotubes exhibit remarkable properties such as superconductivity near room temperature, exceptional thermal conductivity, and unique chemical reactivity. They can be synthesized using methods like sublimation of graphite and electric arc discharge. These nanotubes have the potential to revolutionize various fields including electronics, material science, and sensors due to their exceptional characteristics.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

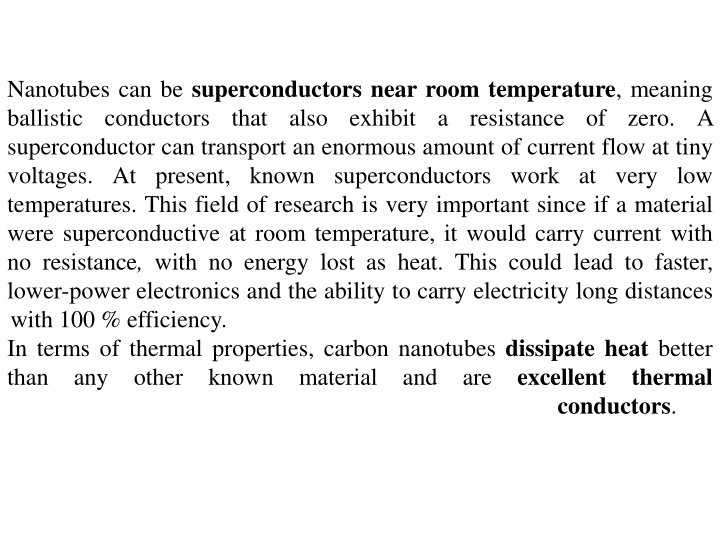

Nanotubes can be superconductors near room temperature, meaning ballistic conductors that also exhibit superconductor can transport an enormous amount of current flow at tiny voltages. At present, known superconductors work at very low temperatures. This field of research is very important since if a material were superconductive at room temperature, it would carry current with no resistance, with no energy lost as heat. This could lead to faster, lower-power electronics and the ability to carry electricity long distances with 100 % efficiency. In terms of thermal properties, carbon nanotubes dissipate heat better than any other known material a resistance of zero. A excellent conductors. thermal and are

Chemical reactivity Carbon nanotubes are very stable: they can withstand the attack of numerous chemicals and resist exposure to a large temperature range. However, their chemical structure can be changed by the addition of specific ligands with functional groups that allow interaction with different chemicals. This allows them to be used in sensors.

Synthesis of CNT There are two main methods for preparation of CNT Sublimation of graphite with subsequent desublimation This method involves condensation of carbon atoms generated from evaporation of solid carbon sources of graphite. The sublimation of the solid can be done using electric arc or laser ablation where the temperature reaches to 2500 -3500 C.

Fig. 1. Schematics for CNT formation by sublimation of graphite with subsequent desublimation.

The electric arc discharge method is one of the efficient techniques for synthesis of CNT. Typically, about 60 to70 wt% of the arc-synthesized soot is CNT. The rest of the soot comprises of fullerenes, amorphous carbon and catalyst nanoparticles. In electric arc discharge production of CNT two graphite rods are used and a current is passed continuously between the electrodes. The anode is drilled and filled with catalysts. The metal oxides (Ni, Co, Fe) are used as catalyst. In some cases the catalyst/graphite composite is used as electrode. The synthesis is performed in cooled chamber in presence of helium, argon or methane environment. During the arcing, the catalyst/graphite anode is evaporated and consumed with simultaneous carbon deposition around the cathode. The quality of CNT samples depends upon arc stability, current density and cooling of cathode. In laser ablation method the graphite target is subjected to laser and sublimated carbon is recollected. Inert gas atmosphere is maintained within the chamber.

Decomposition of carbon containing compounds The most used method to prepare CNT is pyrolysis of hydrocarbon gases or vapors such as propane, butane, hexane, benzene, toluene etc. The method is also known as chemical vapor deposition (CVD) process. Chemical Vapor Deposition ( CVD ) By chemical vapor deposition CNTs can be produced in large quantities. The process temperature can vary from 500 1300 C. The hydrocarbon precursors include CH4, C2H2, C6H6, alcohols etc.

In CVD method there is initial dissociation of hydrocarbons followed by dissolution and saturation of C atoms in metal nanoparticles. Thereafter there is precipitation of carbon. Vapor-grown CNTs generally use metal catalyst particles. Fe, Co and Ni catalysts are mostly used for the catalytic growth of CNT. More recently, CNTs have also been grown from metal such as Au, Ag and Cu. Catalyst serves as nucleation sites and also promotes pyrolysis of hydrocarbons. .

Carbon Nanotubes applications 1. Structural CNTs possesses remarkable properties and qualities as structural materials. Their potential applications include: (a) Textiles CNTs can produce waterproof and tear-resistant fabrics. (b) Body armor CNT fibers are being used as combat jackets. The jackets are used to monitor the condition of the wearer and to provide protection from bullets. (c) Concrete CNTs in concrete increases its tensile strength and halt crack propagation. (d) Polyethylene CNT fibers can be used as polyethylene. The CNT based polyethylene can increase the elastic modulus of the polymers by 30 %.

(e) Sports equipmentGolf balls, golf clubs, stronger and lighter tennis rackets, bicycle parts, and baseball bats. (f) Bridges CNTs may be able to replace steel in suspension and bridges. (g) Flywheels The high strength/weight ratios of CNTs enable very high rotational speeds. (h) Fire protection Thin layers of buckypaper can potentially protect the object from fire. The dense, compact layer of CNT or carbon fibers in the form of buckypaper can efficiently reflect the heat.