Concrete Innovation Journey in Michigan

Explore the fascinating history of concrete innovation in Michigan, from the early milestones in the 1900s to recent advancements like performance specifications, optimized mixtures, and sustainable practices. Discover how collaboration between industry and state entities has led to significant improvements in concrete technology and infrastructure development.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Innovation in Concrete Steve Waalkes, P.E. Director of Engineering W. Mich. Michigan Concrete Association

High Level Overview of Concrete Innovation Competition & communication are the keys to innovation Always lessons to learn have to keep trying, implementing new ideas Solving problems & making improvements before they become problems 2

Long History of Innovation in Michigan 1909 U.S. first full mile of concrete highway, on Woodward Ave., 6 Mile Rd. to 7 Mile Rd. 1911 U.S. first painted centerline 1912 U.S. first highway materials testing lab 1918 U.S. first 4-way red/yellow/green signal 1929 U.S. first paved runways at Ford Airport in Dearborn 1955 World s first freeway-to-freeway interchange 1960 U.S. first state to complete border-to-border interstate (I-94, Detroit to New Buffalo) 3

Recent History of Concrete Innovation in Michigan Mid- 1990 s 1997 Movement towards Performance Related Specifications Midwest Concrete Consortium started (precursor to NC2) state DOT s and industry collaboration Increase in state gas tax funding; included are requirements for pavement warranties and LCCA P1Mod spec first developed by MDOT concrete engineers Re-tooling of the P1Mod spec; requires 3 aggregates, well-graded, optimized blend 2004 4

Recent History of Concrete Innovation in Michigan (cont.) 2005 2006 P1Mod upgraded: stockpile management, process control MCA funded study indicates ASR, air entrainment, and other issues are to blame for some early durability problems I-96 and Ambassador Gateway projects utilize stabilized subgrades Supplementary cementitious materials required at min. of 25% Optimized mixtures for use in bridge elements FHWA, CP Tech Center, and MDOT start NC2 PEM implementation 2010 2015 5

Recent History of Concrete Innovation in Michigan (cont.) 2015 2018 MDOT specs allow ASTM C595 Type IL cement MDOT demonstrates 30- and 50-year designs, utilizing stabilized subgrades (among other improvements) WisDOT adopts optimized/well-graded concrete mixtures New MDOT spec book, P1M now called 3500HP MCA & MDOT discussing innovative concepts including: Stabilized subgrades; Thickened edge for truck lane; Recycling concrete into 3-inch minus material, into subgrade 2020 2021 6

FHWA Emphasis on Pavement Foundation(s) ME designs do not consider the effects of any deterioration or spatial variability in the foundation layers. Over time, the conditions of the foundation layers can degrade and deform under the influence of repeated heavy loads, leading to non- uniform support conditions and localized failures. Thus, the principal role of a robust pavement foundation is ensuring the foundation layers retain their integrity throughout the pavement life. 7

MDOT Specifications: 12SP-604B-11 (Quality Control and Acceptance of Portland Cement Concrete): Required for all trunkline 12SP-604B Moving to new spec. book 3.09 Optimized Aggregate Gradation MDOT MQAP Manual

Maximum Cement Content and W/C: Maximum Cement Content: Pavements: 564 lbs.(6 sack) Bridge Decks: 611 lbs. (6.5 sack) Maximum W/C Ratio: 0.45 Benefits: Reduced paste content Reduced costs associated with cement Difficulties: Dependent on Water Reducing Admixtures Local Cement testing

Supplementary Cementitious Materials: Replacement rates: 25%-40% replacement of Portland cement Replacement amount is determined by the Contractor 40% total replacement Improvements: Permeability Resistance to Freeze-thaw damage Consistency Difficulties: Initial pushback/learning curve Can cause air issues Slower initial strength gains

Optimized Aggregates: Improvements: Slump/Consistency Permeability Additional aggregates gradation used Difficulties: Agency and Contractor understanding MDOT Optimized Aggregate Spreadsheet Ready Mix with limited bins Preblended aggregates 2 aggregate gradation blends

PEM (Performance Engineered Mixtures) Pooled Fund Study 19 state DOT s 4 national industry associations Implement newer technologies to deliver enhanced concrete durability & maximize pavement performance

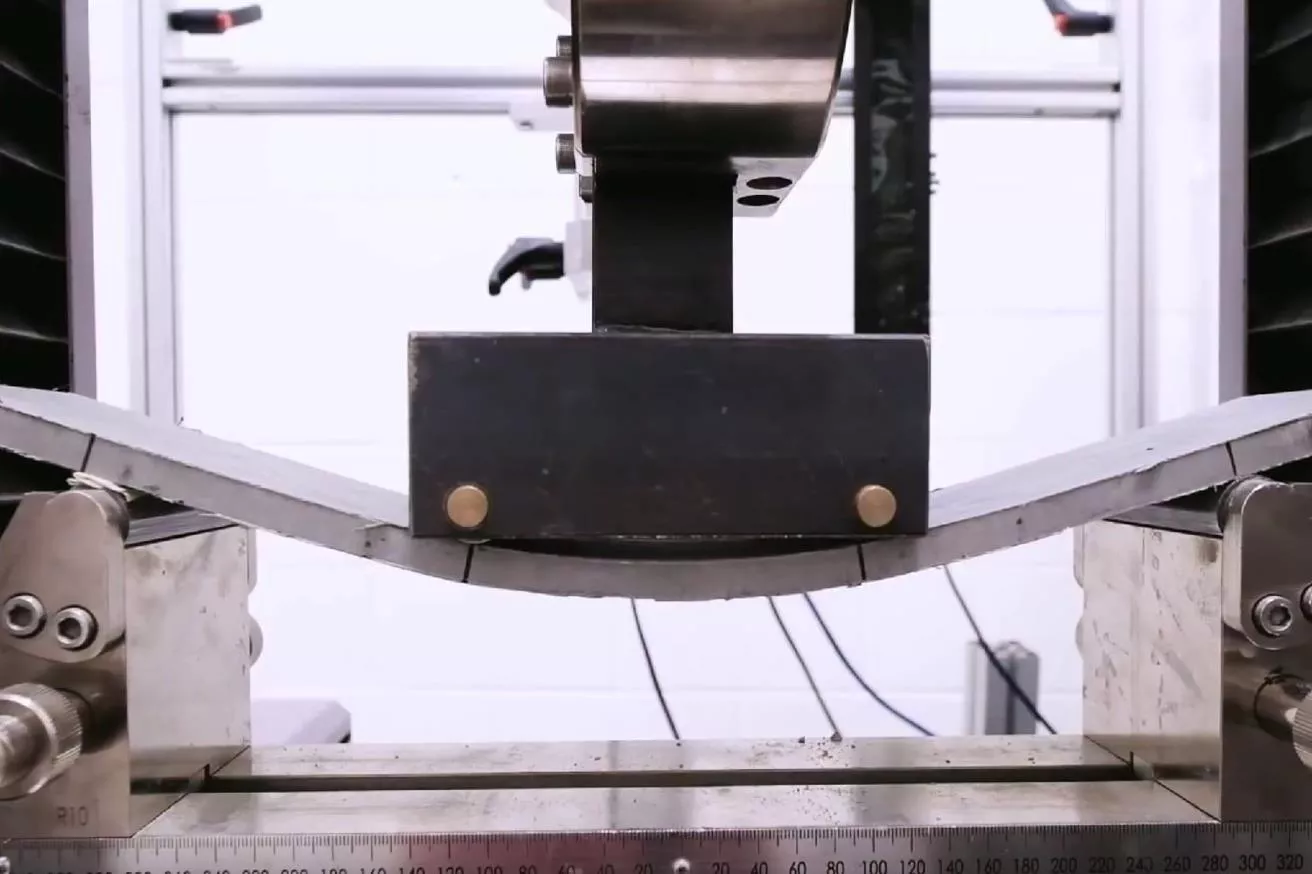

PEM (Performance Engineered Mixtures) V-Kelly Ball (V-Kelly) Box Test Maturity Method Formation Factor Surface Resistivity Bulk Resistivity Sequential Air Metric Apparatus/Super Air Meter (SAM)

PEM Testing V-Kelly Ball (V-Kelly): Has been used in the lab Have not required its use on Projects QC Test

PEM Testing Box Test: Has been used in the lab Have not required its use on Projects Perhaps require its use for trial batches in the future QC Test

PEM Testing Maturity Method: MDOT Special Provision Contractor s option Open to traffic only Training is key: Fingerprints correct Doesn t measure strength development it predicts it

PEM Testing Formation Factor: MDOT has not used the formation factor Mainly focused on resistivity testing

PEM Testing Surface Resistivity: Testing was performed on 2 long-life (30 and 50 year) pavement projects Was being conducted on all freeze-thaw samples 40+ sets of coarse aggregate samples were tested All testing and mix ingredients were provided to Jason Weiss at Oregon State University MDOT s experience: Fairly high level of variability Must hold Probes perpendicular to the surface Ensure the Probes reservoirs are full Keep Probes away from voids and aggregate located on the surface Currently, MDOT has transitioned to Bulk Resistivity

PEM Testing Bulk Resistivity: Used on multiple research & pilot projects MDOT s experience: Simpler test than surface resistivity Consistent results Ensure the sponges remain wet Keep away from metal Correlates with surface resistivity Correlated well with RCP in recent research project

PEM Testing Bulk Resistivity: Currently MDOT is collecting data Performed on all freeze-thaw samples Perhaps require its use for trial batches in the future?

PEM Testing Super Air Meter (SAM): MDOT owns 19 SAMs Introduced to Region personnel Pilot field Testing/Shadow SP: 12CF601 Requires testing for information only: Mainline Pavement Structures Barrier One test per sublot Typically 5 tests per day for mainline paving

PEM Testing Super Air Meter (SAM): Michigan Concrete Association s SAM Certification Class: 2 train-the-trainer classes completed 3 certification classes completed In-field, on-site training in 2020

PEM Testing Super Air Meter (SAM): Shadow SP: 12CF601 Placed in multiple projects: Previous: I-75, Monroe US-131, Grand Rapids (Rockford) I-69, Flint Information provided to Federal Highway and CP Tech Center

PEM Testing Super Air Meter (SAM): Shadow SP: 12CF601 Project Complete in 2020: I-496, Lansing 66 complete samples 2021 Research Project: University of Michigan Hardened air analysis of 75 samples Future projects? Lansing

PEM Testing Super Air Meter (SAM): MDOT s Experience: Introduce the SAM gauge Inspectors experience Time to run the test Do not store wet gauges in cases Do not leave the gauges in the air- conditioned cab prior to testing Always have spare batteries Have a backup gauge Use the Shotgun Follow the gauge s directions

PEM Testing Super Air Meter (SAM): Future Use: QC? Mix Design Verification? Quality Assurance Daily Test? Random number Testing? PWL?

Summary Michigan has a history of innovation More innovation in the works Not all innovations prove themselves to be worth it Concrete open and suited to innovation We have the tools to properly assess Performance Related Specifications and new materials to be added to concrete 27

Special Thanks To: Ethan Bahmer, MDOT CFS Bahmert1@Michigan.gov (517) 230-0190