Comprehensive Guide to Electric Tapping Machines & Their Applications

This detailed guide covers the terminology, types of tap tools, components, and capacities of electric tapping machines. It explains the advantages of electric tapping machines, highlighting their compact design, versatility, and efficiency in various tapping processes. With insights into machine structure, mounting dimensions, and applications in different industries, this guide provides a thorough understanding of electric tapping technology.

Uploaded on Sep 18, 2024 | 2 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

You are allowed to download the files provided on this website for personal or commercial use, subject to the condition that they are used lawfully. All files are the property of their respective owners.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author.

E N D

Presentation Transcript

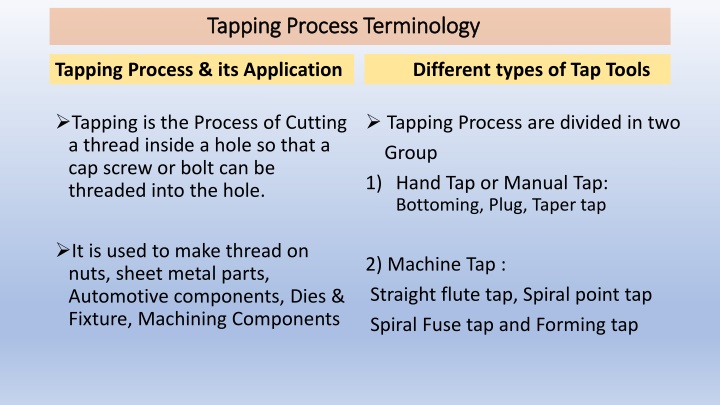

Tapping Process Terminology Tapping Process Terminology Tapping Process & its Application Different types of Tap Tools Tapping is the Process of Cutting a thread inside a hole so that a cap screw or bolt can be threaded into the hole. Tapping Process are divided in two Group 1) Hand Tap or Manual Tap: Bottoming, Plug, Taper tap It is used to make thread on nuts, sheet metal parts, Automotive components, Dies & Fixture, Machining Components 2) Machine Tap : Straight flute tap, Spiral point tap Spiral Fuse tap and Forming tap

Main Component of Electric Tapping Machine Main Component of Electric Tapping Machine Servo Gear Box Servo Motor Control Panel with inbuilt Microprocessor Liquid Spring Tapping Collet Mounting Base Optical Axle Shaft

Machine Mounting Dimension Details Machine Mounting Dimension Details

Machine Structure Machine Structure Total working Arm Length 1MTR Total Machine Height -750 MM Max Tapping Depth with respective mounting Base plate 150 MM Max Job Working Height -350 MM Machine Rotation Angle 360 Degree Weight : DS16 -23Kg, DS30- 43Kg

Machine Capacity : Vertical & Universal Electric Tapping M/C Machine Capacity : Vertical & Universal Electric Tapping M/C ITEM MR-DS16(push-button,vertical type) VOLTAGE 220V/50HZ POWER 600W 0-312RPM TAP RANGE M3-M16 COLLET M3,M4,M5,M6- 8,M10,M12,M14,M16 ITEM MR-DS30(push-button,vertical type) VOLTAGE 220V/50HZ POWER 1200W 0-150RPM TAP RANGE M6-M30 COLLET M6-8,M10,M12,M14,M16,M18- 20,M22,M24,M30

Advantages of Electric Tapping Machine Advantages of Electric Tapping Machine Compact & advanced mechanical design, a variety of processes using mold castings, the overall rigidity is strong, durable, non deformation, beautiful appearance. The machine adopts servo drive control,Gear Box with intelligent torque protection, instead of the traditional lathe, drilling machine or manual tapping limitations. The high definition touch screen is simple and flexible. It can realize the vertical and horizontal work of complex and heavy workpiece, locate quickly, and process accurately. Tapping speed change, manual, automatic, linkage three modes of work, whatever you choose. Automatic mode can effectively control the depth of tapping, without the operation button, automatic control by depth controller. Repeated positioning fast, tapping speed, high production efficiency. By Vibration Mode Eliminate the Tapping Damage. On Manual Tapping Process can measure Tapping Depth.

Usage and Application of Electric Tapping Machine Usage and Application of Electric Tapping Machine Generally Tapping machine can be used in Multiple Industries Shown in Images . Machine Tools Industries Automotive Component Mfg. Industries Tool and Die Making Industries Sheet Metal Industries. Heavy Fabrication Industries. Any Kind of Manufacturing Industries.