Complete Boiler Control System Overview by Preferred Instruments

Explore the BurnerMate Universal Boiler Control System by Preferred Instruments, a comprehensive solution for efficient boiler control. This system includes components such as the Controller Chassis, High Precision Servos, and LCD Interface, offering advanced features like flame safeguard control, O2 trim, and draft control. With over a century of expertise, Preferred Instruments is a trusted manufacturer known for linkage-less controls and exceptional field service support.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

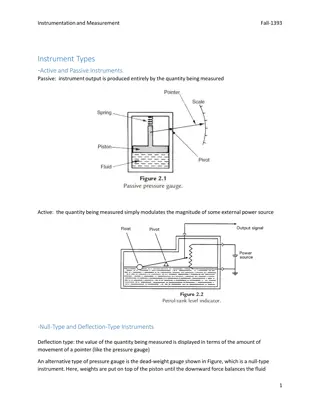

BurnerMate Universal A Complete Boiler Control System

PREFERRED UTILITIES MFG CORP 31-35 South St. Danbury CT T: (203) 743-6741 F: (203) 798-7313 www.PREFERRED-MFG.com

Preferred Instruments Preferred Instruments Combustion and control business since 1920. Only domestic manufacturer of linkage-less controls. Only manufacturer with significant field service department. Strong network of representatives are boiler/burner/controls experts.

Preferred Instruments new Preferred Instruments new BurnerMate BurnerMate Universal Universal Linkage-less controller incorporating: Flame safeguard control Parallel positioning combustion control w/ O2 trim Draft control Drum level control And a whole lot more

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components Controller Chassis: Includes separate processors for FSG and combustion control in accordance with NFPA 85 paragraph 1.9.3.2.3. Designed for sub-panel mounting. Wiring is by quick disconnect terminal blocks.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components High Precision Servos: Available in 3, 15, 37, 70, 140, 280, 420, and 720 ft-lb torques. Triac input with feedback pot allows 0.1 accuracy. All servos are daisy-chained on one digital loop. Mounting kits are available for most existing valves & dampers.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components System Components LCD Interface (required): Can be flush-mounted on BMS enclosure or mounted to BMU chassis. 4 x 20 character display is the primary interface to the controller. Displays boiler status, alarms, annunciations, event history, etc.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components System Components Optional 10 touch-screens available. Graphical interface provides additional information, easier operator interface. Modbus, Ethernet, and web-based communications are included for interfacing with EMS, BAS, or other LAN networks. Designed to be flush-mounted in the BMS enclosure or remote-mounted.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Touch Screen Graphics Touch Screen Graphics Boiler overview screens provide current boiler operating conditions in an easy-to-understand graphical format.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Touch Screen Graphics Touch Screen Graphics Color touch screens include walk-thru s for easy controller configuration.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Touch Screen Graphics Touch Screen Graphics Loop tuning screens provide familiar loop controller faceplates for easy configuration. Over 75 screens are pre-configured.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components System Components Optional Communications Module: Inexpensive module allows Modbus, Ethernet, and web- based remote monitoring. BMU Modbus addresses are pre- programmed. Designed to be sub-panel mounted.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller System Components System Components Preferred supplies a choice of three flame scanners: IR, UV, and self-checking UV. All flame scanners use identical military-style quick connect fittings. The BMU will accept any U.L. listed flame scanner.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Flame Safeguard Functions Flame Safeguard Functions Stages the burner through purge, lightoff, main flame, and shutdown. Supports up to three fuels (oil, natural gas, and a second gas fuel) Fuel changeover can be initiated locally or remotely. Monitors up to 6 recycling limits, up to 33 shutdown limits and one or two flame scanners. All limit inputs are 120 VAC, wired in parallel, and separately annunciated. During a shutdown, all major status bits are recorded and saved for up to the last ten lockouts. Adjustable time delays are available for many limits to avoid nuisance trips.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Flame Safeguard Functions Flame Safeguard Functions Optional gas valve leak test logic. Optional oil gun purge logic (blow-thru into the furnace, or suctioned back out of the gun via scavenger pump) High flue gas temperature shutdown (added dry boiler protection)

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Fuel Fuel- -Air Ratio Control Functions Air Ratio Control Functions Jackshaft or parallel positioning combustion control is supported. Up to 8 analog outputs available for fuel/air servos, and VSD s for FD fan, FGR fan, and ID fan. Up to 15 combustion control points can be programmed. Off-curve points available for standby, purge, and light- off positions. Optional O2 trim control is supported. Separate curves available for VSD by-pass mode (in case of VSD failure)

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Fuel Fuel- -Air Ratio Control Functions Air Ratio Control Functions Low fire and high fire rate limits can be temporarily configured to limit burner travel. Problematic firing rates can be configured to be skipped over until the problem is resolved. Burner can be warm-up slowly until FGR temperature reaches setpoint.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Boiler Control Functions Boiler Control Functions Single, two, or three-element PID feedwater control Adjustable draft control is fully integrated into flame safeguard and fuel-air control algorithms. Firing rate is used as a feed forward for both drum level and draft control. VSD outputs available for ID fan and feedwater pump.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Boiler Control Functions Boiler Control Functions Remote setpoint and remote firing rate control. Outdoor air temperature reset Warm standby and domestic hot water override Low fire hold based on boiler shell or flue gas temperature. Steam pressure or hot water control supported. Five auxiliary relays can be configured to control additional boiler auxiliaries. Supervised or automatic water column blowdown & low water level test logic. Boiler cold start function allows for adjustable boiler thermal shock protection.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Ease of Operation Ease of Operation No special sensors are required (common switches and transmitters can be used) Preferred supplies flame scanners, or any U.L. listed scanners can be used. (BMU provides 120 VAC and 24 VDC power, and accepts a contact closure for proof of flame and analog input for optional flame intensity. Servo set-up is easy, intuitive, and well-documented. 33 basic parameters configure most control functions. Flame safeguard logic is designed to U.S. standards (NFPA 85)

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Security Features Security Features Servos are locked into place on the fuel air curves. Putting a servo in manual will trip the burner. Safety related parameters can only be changed when the burner is off-line. Fuel-air curve points must be verified before the technician can exit commission mode. Four levels of password security enable operators, technicians, engineers, and Preferred factory personnel access to parameter settings.

BurnerMate BurnerMate Universal Boiler Controller Universal Boiler Controller Product Support Product Support BMU is Made in America. It is available only through Preferred and it s factory trained representatives. All components are in stock. It is supported from the Preferred Utilities factory in Connecticut, outside sales offices in Massachusetts, Illinois, Texas, and Oregon, and factory trained representatives around the country. Preferred has service engineers located throughout the U.S.